Rapid denture forming method and rapid denture forming device

A molding method and molding device technology, applied in the field of 3D printing, can solve the problems of long processing cycle of denture molding production plan, poor matching of denture oral teeth, and increased manufacturing cost of dental restorations, so as to shorten molding time and production cost Reduced and high molding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

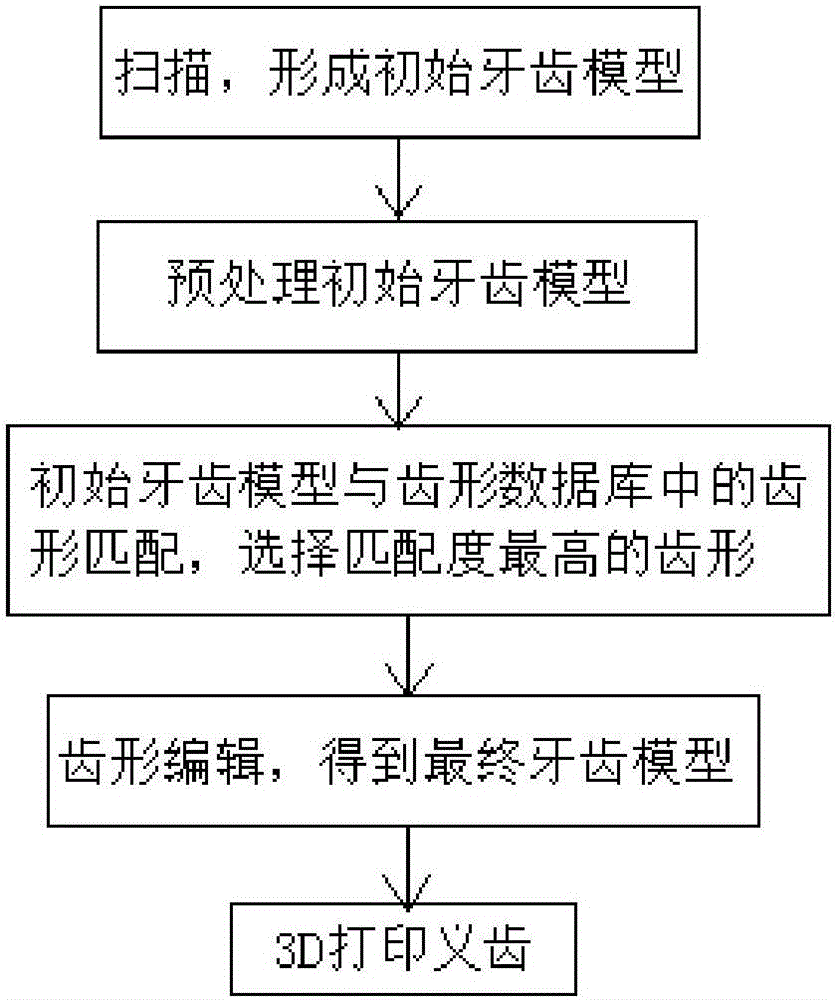

[0036] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0037] A rapid prototyping device for dentures, comprising

[0038] An oral scanner for scanning the teeth in the oral cavity to form an initial tooth model;

[0039] A preprocessing module is used to preprocess the initial tooth model;

[0040] The matching module is used to match the preprocessed tooth model with the tooth shape in the tooth shape database, and select the tooth shape with the highest matching degree;

[0041] The tooth shape editing module is used to edit the selected tooth shape according to the international denture repair standard to obtain the final tooth model;

[0042] 3D printers for printing out dentures based on the resulting tooth models.

[0043] A memory is also included, the storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com