Welding method for tapered aluminum product

A welding method and variable wall thickness technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve problems such as welding defects that are prone to occur, reduce the generation of welding pores and micro-cracks, meet the welding seam penetration, Ensure the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

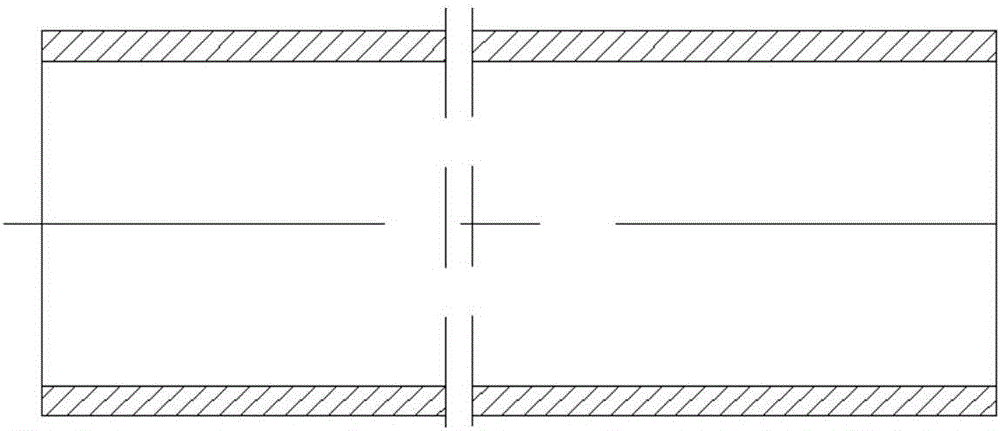

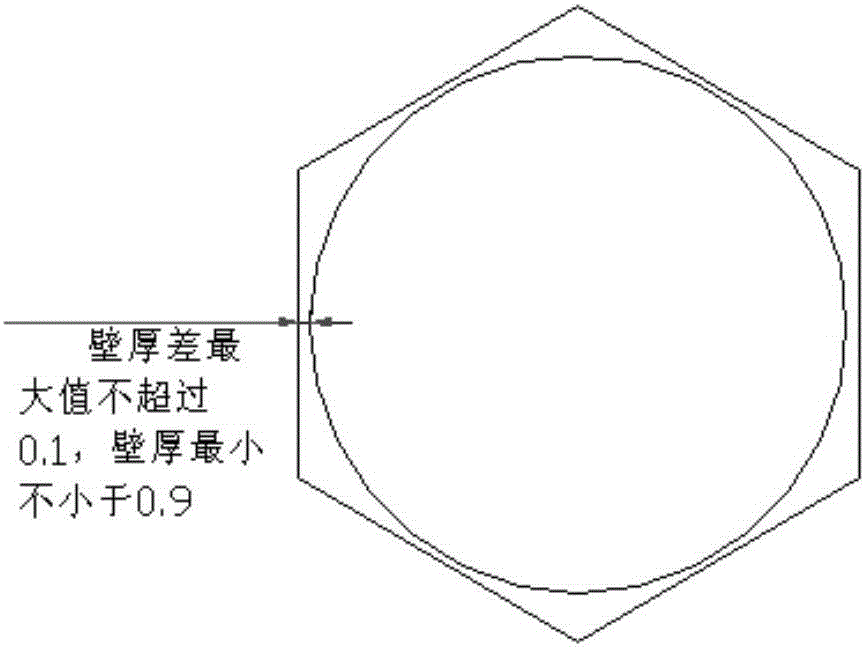

[0030] Depend on figure 1 and figure 2 As shown, the hexagonal tube has an outer square inner circle structure, where the wall thickness is the largest at the sharp corners, with a maximum thickness of 6.4mm; the wall thickness is the smallest at the middle of the plane, with a minimum thickness of 1mm.

[0031] The hexagonal tube and the joint are made of LT24 aluminum alloy. The hexagonal tube and the joint are connected by welding. The depth of the welded joint changes cyclically. The depth of the thinnest part of the joint is 1mm, and the maximum is 6.4mm, and the welding plane transition is not arc transition. , but directly transitioned at an angle of 120°, this structure brings great difficulties to the welding process.

[0032] Using a variable-wall-thickness aluminum material welding method according to the present invention to connect the aluminum weldment hexagonal pipe with the joint by welding, it includes the following steps:

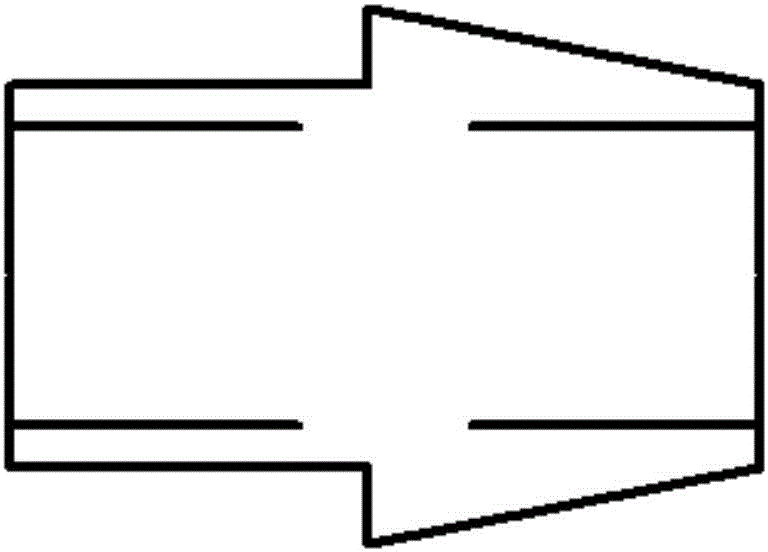

[0033] (a) Beveling the hexagona...

Embodiment 2

[0040] Depend on figure 1 and figure 2 As shown, the hexagonal tube has an outer square inner circle structure, where the wall thickness is the largest at the sharp corners, with a maximum thickness of 6 mm; the wall thickness is the smallest at the middle of the plane, with a minimum thickness of 0.6 mm.

[0041] The hexagonal tube and the joint are made of 6061 aluminum alloy, and the hexagonal tube and the joint are connected by welding. The transition of the welding plane is not an arc transition, but a direct transition at an angle of 120°.

[0042] Using a variable-wall-thickness aluminum material welding method according to the present invention to connect the aluminum weldment hexagonal pipe with the joint by welding, it includes the following steps:

[0043] (a) Beveling the hexagonal tube of the aluminum weldment, that is, performing mechanical beveling on the six edges of the hexagonal tube, such as Image 6 As shown, the groove size is 30°×2mm.

[0044] (b) Car...

Embodiment 3

[0050]Depend on figure 1 and figure 2 As shown, the hexagonal tube has an outer square inner circle structure, where the wall thickness is the largest at the sharp corners, with a maximum thickness of 7mm; the wall thickness is the smallest at the middle of the plane, with a minimum thickness of 1.5mm.

[0051] The hexagonal tube and the joint are made of LT24 aluminum alloy, and the hexagonal tube and the joint are connected by welding, which includes the following steps:

[0052] (a) Beveling the hexagonal tube of the aluminum weldment, that is, performing mechanical beveling on the six edges of the hexagonal tube, such as Image 6 As shown, the groove size is 40°×4mm.

[0053] (b) Surface treatment of the hexagonal tube, 5 minutes of alkali washing and 10 minutes of pickling to clean the oil and oxide film on the surface of the weldment; then dry the hexagonal tube after surface treatment; the drying device uses far infrared rays Heated blast circulation drying box, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com