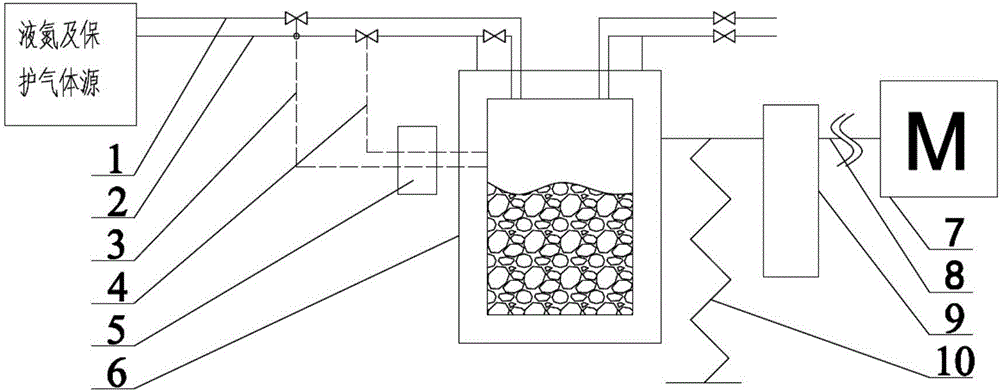

Equipment and method for preparing nanocrystal powder through vibration type copious cooling ball milling

A vibration-type, nano-crystalline technology, applied in the field of low-temperature ball milling, can solve the problems of low working temperature, reduce the dynamic recovery ability of powder deformation, etc., and achieve the effect of high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

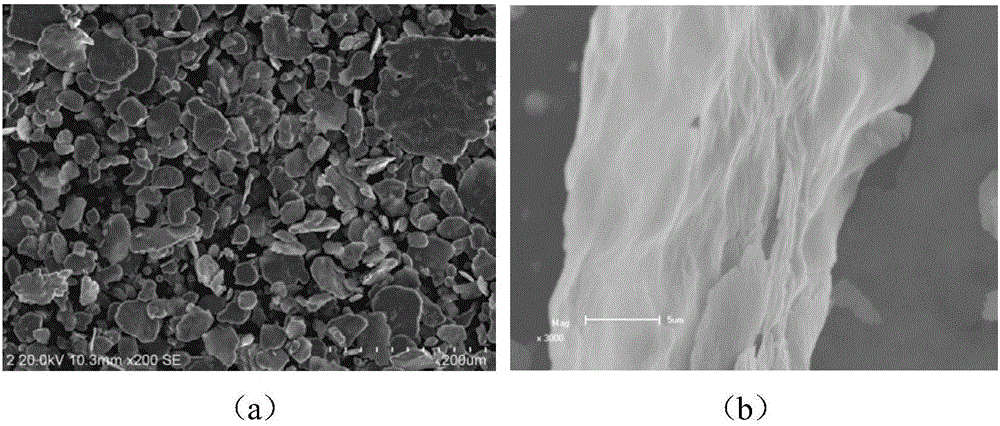

[0036] In this example, commercial gas-atomized aluminum powder with a primary grain size of about 1-5 μm was ball-milled. Ball milling temperature -180°C, ball milling amplitude 5mm, vibration frequency 50Hz, ball milling time 2 hours, using stainless steel balls, mass ratio of ball to material 10:1, adding stearic acid amount to 2% of the mass of the abrasive, and preparing a thickness of 100-200nm The two-dimensional sheet-like nanocrystalline powder, the grain size is about 35nm.

Embodiment 2

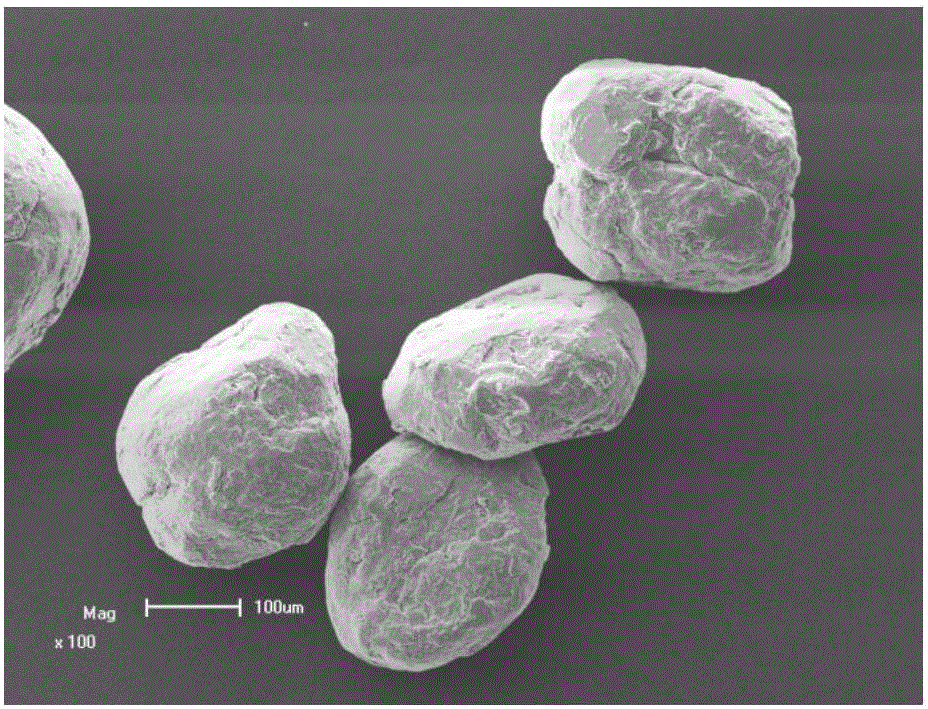

[0038] In this example, commercial gas-atomized aluminum powder with a primary grain size of about 1-5 μm was ball-milled. Milling temperature -180°C, ball milling amplitude 6 mm, vibration frequency 50 Hz, ball milling time 4 hours, using stainless steel balls, ball-to-material mass ratio 10:1, after adjusting the size of the balls, it can produce concentrated particle size distribution, D50 in the range of 15-500 μm Precisely controlled equiaxed nanocrystalline powder, the grain size is about 50nm.

Embodiment 3

[0040] In this example, commercial gas-atomized aluminum powder with a primary grain size of about 1-5 μm was ball-milled. Milling temperature -180°C, ball milling amplitude 4mm, vibration frequency 50Hz, ball milling time 2 hours, using stainless steel balls, ball to material mass ratio 10:1, after adjusting the size of the balls can be prepared with concentrated particle size distribution, D50 in the range of 15 ~ 500μm Precisely controlled equiaxed ultrafine crystal powder body, the grain size is about 200nm.

[0041] Such as figure 2 Shown, adopt the SEM photo of the two-dimensional sheet-shaped powder prepared by ball milling of the present invention, as can be seen from figure (a) that the powder is on the micron scale in two dimensions; as can be seen from figure (b) that the two-dimensional sheet-formed powder The thickness is about 100-200nm.

[0042] Such as image 3 , Figure 4 As shown, the SEM photographs of nanocrystalline powders with D50=400 μm and D50=100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com