Composition for forming cured film, orientation material, and retardation material

A curing film and composition technology, applied in liquid crystal materials, chemical instruments and methods, instruments, etc., can solve problems such as difficulty in improving contrast ratio and brightness, response speed, less brightness change/color change, low contrast ratio, etc., to achieve The effect of excellent vertical alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

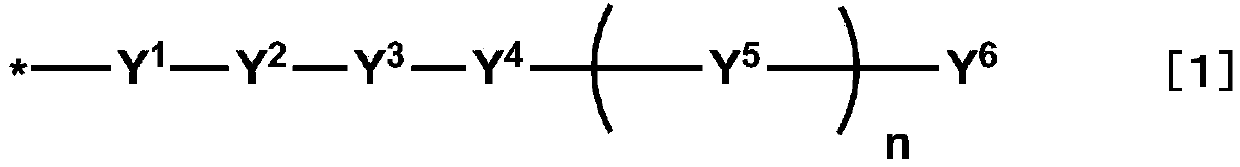

[0302]

[0303] The cured film forming composition of this invention contains the polymer of (A) component, the crosslinking agent of (B) component, and the adhesion accelerator of (C) component, and / or (D) the heat-crosslinkable group Agglomerated polymers may contain a crosslinking catalyst as component (E) if desired, and may contain other additives as long as the effect of the present invention is not impaired. And usually, these are used in the form of the solution which melt|dissolved in the solvent.

[0304] Preferred examples of the cured film-forming composition of the present invention are as follows.

[0305] [1]: A cured film forming composition comprising (A) component, 1 to 300 parts by mass of (B) component based on 100 parts by mass of (A) component, and The total amount of 100 parts by mass of the polymer and the crosslinking agent as component (B) is at least one of component (C) of 0.1 to 100 parts by mass and component (D) of 1 to 400 parts by mass .

...

Embodiment

[0322] The following examples are given to illustrate the present invention in more detail, but the present invention is not limited to these examples.

[0323] [Abbreviated symbols used in Examples]

[0324] The meanings of the abbreviations used in the following examples are as follows.

[0325]

[0326] LAA: lauryl acrylate

[0327] PAA: palmityl acrylate

[0328] LAMA: lauryl methacrylate

[0329] HEMA: 2-Hydroxyethyl methacrylate

[0330] MMA: methyl methacrylate

[0331] BzMA: benzyl methacrylate

[0332] BMAA: N-Butoxymethacrylamide

[0333] GMA: glycidyl methacrylate

[0334] AIBN: α,α'-azobisisobutyronitrile

[0335] A1: 2-(((4-(4'-pentyl-[1,1'-bis(cyclohexane)]-4-yl)phenoxy)carbonylamino)ethyl methacrylate

[0336]

[0337] A2: 6-(4-(4-heptylcyclohexyl)phenoxy)hexyl methacrylate

[0338]

[0339]

[0340] HMM: Melamine crosslinking agent represented by the following structural formula [Cymel (CYMEL) (registered trademark) 303 (manufactured by Mits...

Synthetic example 1

[0382] Synthesis of compound [DM-1]

[0383]

[0384] Under nitrogen flow, at room temperature, 500 g of ethyl acetate, 35.5 g (0.300 mol) of 1,6-hexanediol, 1,8-diazabicyclo[5.4.0]- 1.80 g (11.8 mmol) of 7-undecene (DBU) and 0.45 g (2.04 mmol) of 2,6-di-tert-butyl-p-cresol (BHT) were stirred by a magnetic stirrer, and the temperature was raised to 55°C. Add 95.9 g (0.679 mol) of ethyl acrylate 2-isocyanate dropwise to the reaction solution, stir for 2 hours, then use high performance liquid chromatography to analyze the reaction solution, and the area percentage of the intermediate is less than 1% end the reaction. After adding 328 g of hexane and cooling to room temperature, the precipitated solid was washed twice with 229 g of hexane and dried to obtain compound [A-a] (104 g, 0.260 mol, yield: 86.7%).

[0385]

[0386] Under nitrogen flow, put 1330g of dichloromethane, 100g (0.250mol) of compound [A-a], and 22.5g (0.749mol) of paraformaldehyde in a 2L four-necked b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com