Go-Nafion composite film Ag/AgCl reference electrode for ocean exploration and preparation method thereof

A reference electrode and composite membrane technology, applied in the field of electrochemistry, can solve the problems of poor resistance to seawater interference, poor pressure resistance, and low life, and achieve the effects of improved mechanical strength, excellent performance, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

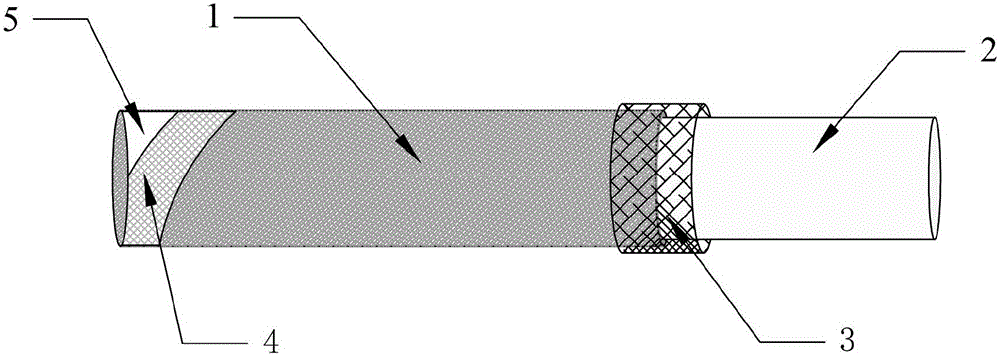

[0029] 1) Preparation of bare Ag / AgCl electrode: Cut a piece of silver wire with Φ=0.5mm and L=25mm, ultrasonically clean it in 1.6M HCl, acetone and ultrapure water for 20 minutes, weld a piece of platinum wire to draw ohmic potential, The silk was immersed in 0.2M HCl solution with a current density of 0.5mA / cm 2 Anodized silver wire, a layer of gray-black silver chloride layer is grown on the silver substrate;

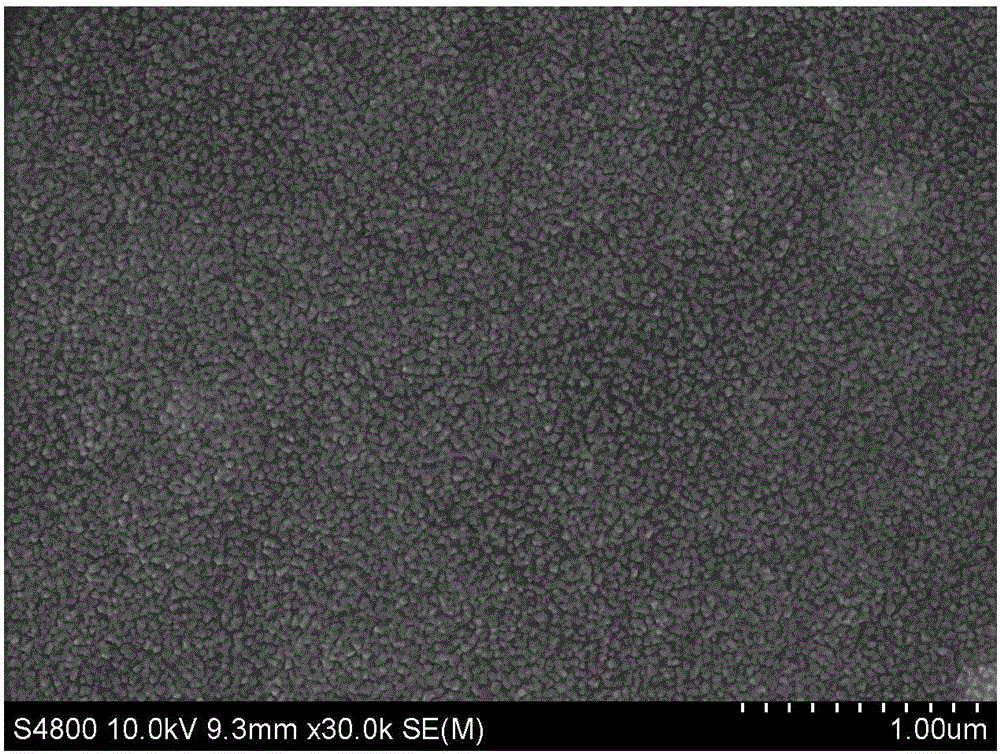

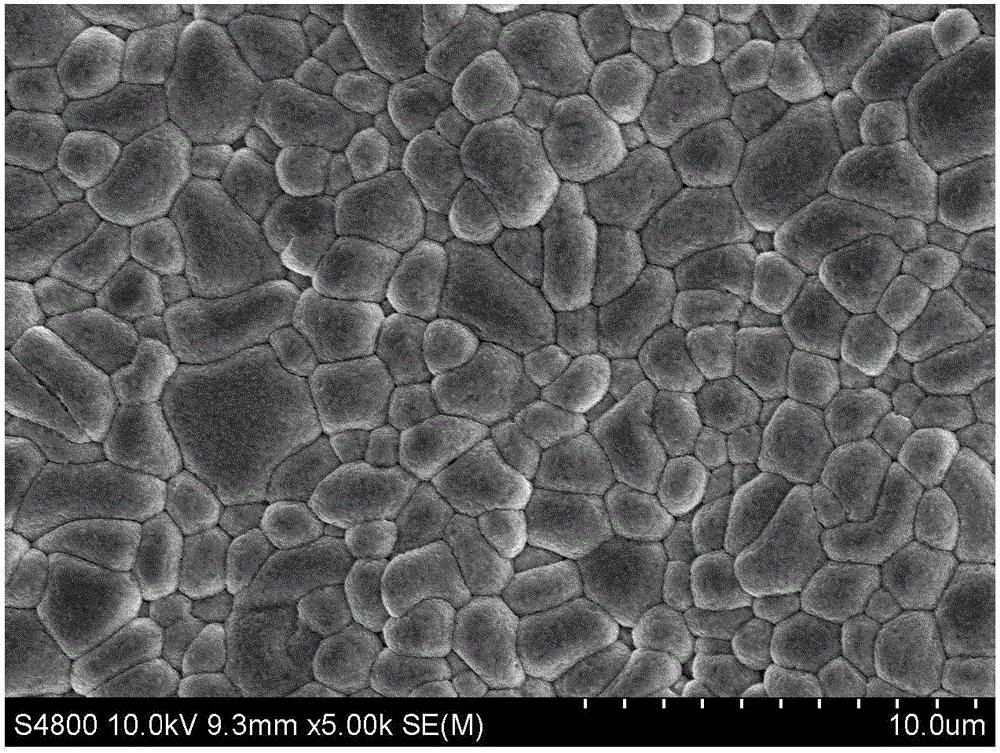

[0030] 2) Preparation of the composite film Ag / AgCl electrode: Take the electrode prepared in (1) and keep it at 400°C for 1.5h at a heating rate of 2°C / min, with 0.5mg / L Go and 30wt% Nafion at a volume ratio of 20: 1 The Go-Nafion composite solution configured in 1 electrophoretically deposits Go-Nafion on the electrode surface, the deposition time is 30s, and the heating rate is 2°C / min in the atmosphere furnace, N 2 After being treated at 300°C for 2 hours in the atmosphere, it was activated in 3.5wt% NaCl solution for 4 hours and packaged to obtain an all-solid...

Embodiment 2

[0032] 1) Preparation of bare Ag / AgCl electrode: cut a piece of Φ=0.64mm, L=20mm silver wire, ultrasonically clean it in 1.6M HCl, acetone and ultrapure water for 30min respectively, weld a piece of platinum wire to draw ohmic potential, and connect the silver wire Immerse in 0.1M HCl solution, with a current density of 0.9mA / cm 2 Anodize the silver wire for 2 hours, and grow a layer of gray-black silver chloride layer on the silver substrate;

[0033]2) Preparation of composite film Ag / AgCl electrode: Take the electrode prepared in (1) and keep it at 300°C for 2 hours at a heating rate of 2°C / min, and use 0.33mg / L Go and 30wt% Nafion in a volume ratio of 40:1 The configured Go-Nafion composite solution was electrophoreticly deposited Go-Nafion on the electrode surface, and the deposition time was 20s; the heating rate was 2°C / min in the atmosphere furnace, and the N 2 After being treated at 300°C for 2 hours in the atmosphere, it was activated in 3.5wt% NaCl solution for 6 h...

Embodiment 3

[0037] 1) Preparation of bare Ag / AgCl electrode: cut a piece of Φ=0.5mm, L=25mm silver wire, ultrasonically clean it in 1.6M HCl, acetone and ultra-pure water for 30 minutes, weld a piece of platinum wire to draw ohmic potential, and connect the silver wire Immerse in 0.5M HCl solution with a current density of 1.5mA / cm 2 Anodize the silver wire for 1.5h, and grow a layer of gray-black silver chloride layer on the silver substrate;

[0038] 2) Preparation of composite film Ag / AgCl electrode: Take the electrode prepared in (1) and keep it at 400°C for 2 hours at a heating rate of 2°C / min, and use 0.6mg / L Go and 30wt% Nafion in a volume ratio of 50:1 The configured Go-Nafion composite solution was electrophoreticly deposited Go-Nafion on the electrode surface, and the deposition time was 60s; 2 After being treated at 200°C for 3 hours in the atmosphere, it was activated in 3.5wt% NaCl solution for 8 hours and then packaged to obtain an all-solid-state reference electrode with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com