Waste battery recovery device used for building

A technology of waste batteries and recycling devices, applied in vertical pipelines, building components, buildings, etc., can solve the problems of lack of funds and policy guidance, lack of social recycling system, and weak public awareness of environmental protection, so as to reduce the burden on the government and endure Guaranteed corrosion performance and reduced recycling labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

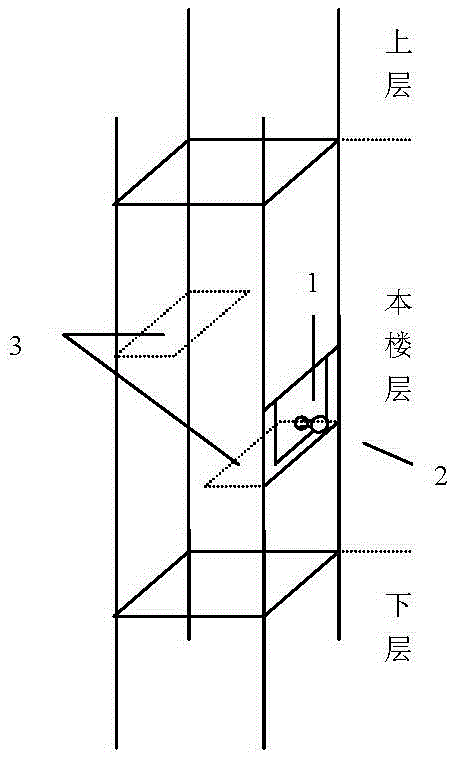

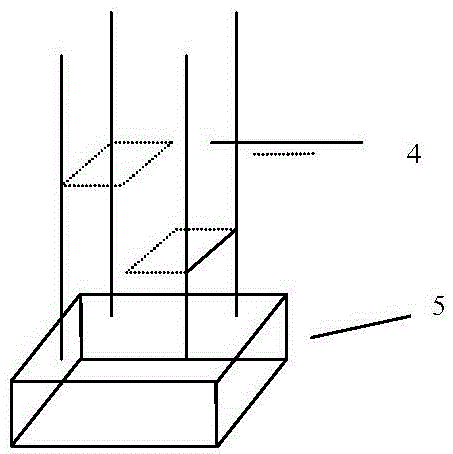

[0025] Such as Figure 1-3 As shown, a waste battery recovery device for buildings is characterized in that:

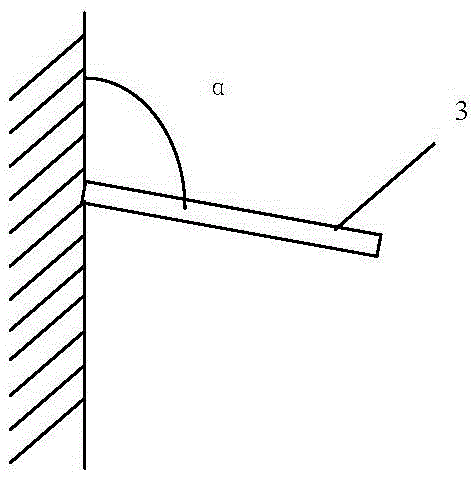

[0026] The device is a rectangular parallelepiped-shaped battery recovery passage, which runs through the top floor to the basement floor, and each floor from the top floor to the basement floor is provided with two rectangular shrapnel (3), one of which is adjacent to the indoor side The height of the shrapnel from the ground is 1 / 3 of the height of the floor, and the height of the shrapnel away from the indoor side is 2 / 3 of the height of the floor; the thickness of the shrapnel is 1mm, and the angle α with the upper wall is 100°. The material is corrosion-resistant austenitic Fe-Cr-Ni type alloy stainless steel. The chemical composition of the alloy is: C 0.03-0.3, N 0.12-0.32, Mo 1.6-2.0, Si 1.1-1.6, Cr 19-21, Ni 9 -11, Mn1.8-2.2, Fe is the balance; the excellent corrosion resistance of the shrapnel ensures the weather resistance of the recovery device, and it is...

Embodiment 2

[0030] The collection box of used batteries is collected once every six months, and the rest is the same as in Example 1.

Embodiment 3

[0032] The cross-section of the battery recovery channel is designed as a square with a side length of 10-20 cm, and the rest is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com