Outdoor waterproof antibacterial superfine fiber synthetic leather and finishing method thereof

A technology of superfine fiber and synthetic leather, which is applied in the fields of application, clothing, textiles and papermaking, etc. It can solve the difference between waterproof and antibacterial effects, unstable finishing technology of waterproofing agent and antibacterial agent, unstable waterproof and antibacterial microfiber leather technology, etc. problem, to achieve the effect of good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Padding finishing agent: impregnate the microfiber suede leather in the finishing agent, 4 dips and 4 pads, with a liquid retention rate of 55%, drying at 130°C for 10 minutes, then cooling and winding.

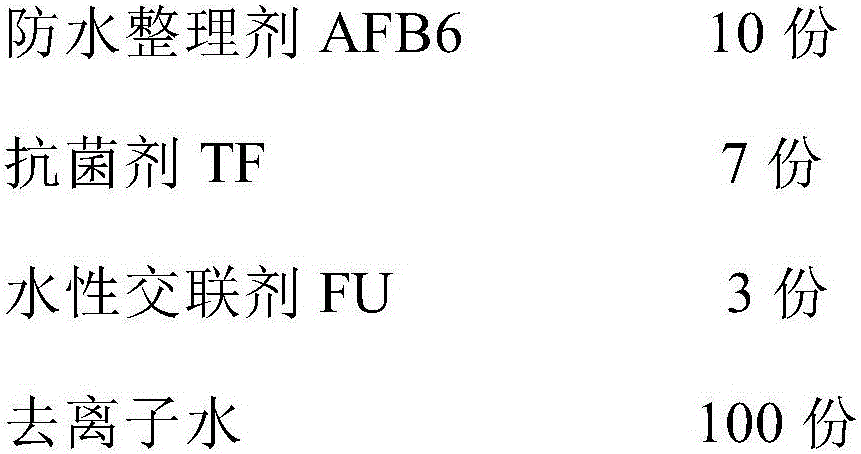

[0028] The finishing agent is composed of the following components in parts by weight:

[0029]

[0030] Adjust the pH to 4.5 with acetic acid

[0031] (2) Printing antibacterial agent: apply oily antibacterial agent ATE 9280 on the front and back of the microfiber leather,

[0032] The amount of roller coating is 2g / m 2 , and then dried at 120°C, and finally cooled and rolled.

[0033] The microfiber leather obtained by this process can achieve the following effects:

[0034] Water absorption rate 5.2%, water penetration 0.02g, water vapor penetration 10mg / cm 2 h (test standard ISO 20345); meanwhile, anti-Klebsiella pneumoniae is 95%, (test standard ATCC 4352), and anti-Staphylococcus aureus is 93% (test standard ATCC 6538).

Embodiment 2

[0036] (1) Padding finishing agent: impregnate the microfiber suede leather in the finishing agent, 4 dips and 4 pads, with a liquid retention rate of 60%, drying at 135°C for 12 minutes, then cooling and winding.

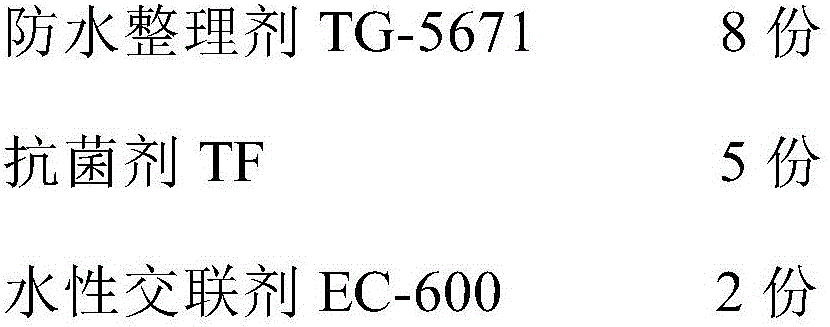

[0037] The finishing agent is composed of the following components in parts by weight:

[0038]

[0039]

[0040] Adjust the pH to 5 with acetic acid

[0041] (2) Printing antibacterial agent: apply oil-based antibacterial agent ATE 9280 on the front and back of the microfiber leather, and the amount of roller coating is 7g / m 2 , and then dried at 120°C, and finally cooled and rolled.

[0042] The microfiber leather obtained by this process can achieve the following effects:

[0043] Water absorption rate 9.9%, water penetration 0.15g, water vapor penetration 13mg / cm 2 h (test standard ISO 20345); meanwhile, anti-Klebsiella pneumoniae is 92% (test standard ATCC 4352), and anti-Staphylococcus aureus is 94% (test standard ATCC 6538).

Embodiment 3

[0045] (1) Padding finishing agent: impregnate the microfiber suede leather in the finishing agent, 4 dips and 4 pads, with a liquid retention rate of 60%, drying at 135°C for 10 minutes, then cooling and winding.

[0046] The finishing agent is composed of the following components in parts by weight:

[0047]

[0048] Adjust the pH to 5 with acetic acid

[0049] (2) Printing antibacterial agent: apply oily antibacterial agent SKANEòM-8 on the front and back of the microfiber leather, and the amount of roller coating is 10g / m 2 , and then dried at 120°C, and finally cooled and rolled.

[0050] The microfiber leather obtained by this process can achieve the following effects:

[0051] Water absorption rate 4.3%, water penetration 0.02g, water vapor penetration 11mg / cm 2 h (test standard ISO 20345); meanwhile, anti-Klebsiella pneumoniae is 91% (test standard ATCC 4352), and anti-Staphylococcus aureus is 92% (test standard ATCC 6538).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com