High-tearing-intensity high-temperature vulcanized silicon rubber, and preparation method and application thereof

A high-tear strength, high-temperature vulcanization technology is applied in the field of vulcanized silicone rubber to achieve the effect of improving tear strength, simple production process, and widening application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

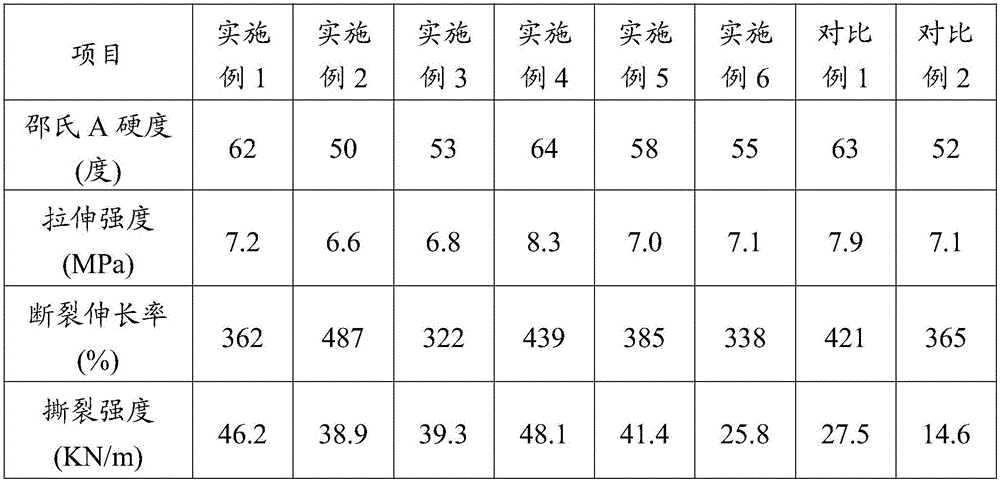

Examples

Embodiment 1

[0069] Add 8 parts of α,ω-dihydroxy polydimethylsiloxane (viscosity: 30mPa. s), 50 parts of fumed silica (specific surface area: 300m 2 / g), fully kneaded in a kneader for 2 hours (room temperature), then kneaded at 170°C for 4 hours under normal pressure; finally at 170°C, kneaded for 2 hours under vacuum-0.1MPa conditions, and obtained For rubber compound I containing vulcanizing agent, place the rubber compound I at room temperature for 24 hours, then cool to room temperature for use.

[0070] Add 0.5 part of triallyl isocyanurate to 100 parts of rubber compound I, and knead at 150°C for 1 hour to prepare compound rubber II containing additives, and cool the compound rubber II to room temperature stand-by. Add 0.5 parts of vulcanizing agent bis(2,4-dichlorobenzoyl peroxide) to the rubber compound II, and mix it on a two-roll mill for 5 times to prepare the rubber compound III containing the vulcanizing agent.

[0071] Feed the mixed rubber III containing vulcanizing agen...

Embodiment 2

[0074] In 100 parts of methyl vinyl silicone rubber raw rubber (vinyl mole fraction: 0.08%, average molecular weight: about 800,000), add 6 parts of diphenylsilanediol, 55 parts of fumed silica (specific surface area: 150m 2 / g), fully kneaded for 2 hours (room temperature) in a kneader, then kneaded for 4 hours at 180°C under normal pressure conditions; finally kneaded for 2 hours at 180°C under vacuum-0.1MPa conditions, and obtained For rubber compound IV containing vulcanizing agent, place the rubber compound IV at room temperature for 24 hours, and cool to room temperature for use.

[0075] Add 3 parts of tetramethyltetravinyl cyclotetrasiloxane and 3 parts of vulcanizing agent benzoyl peroxide to 100 parts of rubber compound IV, and mix Botong 5 times on a double-roller mill to obtain a vulcanized Agent compound V.

[0076] Feed the mixed rubber V containing vulcanizing agent into the rubber strainer to obtain a mixed rubber material with a diameter of 4 cm, feed the mi...

Embodiment 3

[0079] In 100 parts of methyl vinyl silicone rubber raw rubber (vinyl mole fraction: 0.25%, average molecular weight: about 500,000), add 10 parts of dihydrocarbyl dialkoxysilane, 40 parts of fumed silica (specific surface area : 300m 2 / g), 10 parts of precipitated silica (specific surface area: 150m 2 / g), 3 parts diatomite (specific surface area: 10m 2 / g) Fully knead in a kneader for 2 hours (at room temperature), then knead at 170°C for 4 hours under normal pressure; finally knead at 170°C for 2 hours under vacuum-0.1MPa to obtain Vulcanizing agent compound VI, place the compound VI at room temperature for 24 hours, cool to room temperature for use.

[0080] Add 1 part of ethoxylated trimethylolpropane triacrylate, 1.5 parts of tert-butyl peroxybenzoate and 0.5 part of benzoyl peroxide to 100 parts of rubber compound VI, and mix thin pass on a double-roller mill. 5 times, the mixed rubber VII containing vulcanizing agent was obtained.

[0081] Feed the mixed rubber VI...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com