Ultra-low-temperature-resistant antistatic polypropylene composition and preparation method thereof

A polypropylene composition and antistatic technology, applied in the field of polypropylene composite materials, can solve problems such as static spark discharge, material damage, explosion and fire in chemical product warehouses, and achieve good low-temperature impact toughness, good dimensional stability, and antistatic good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

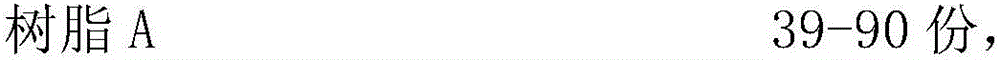

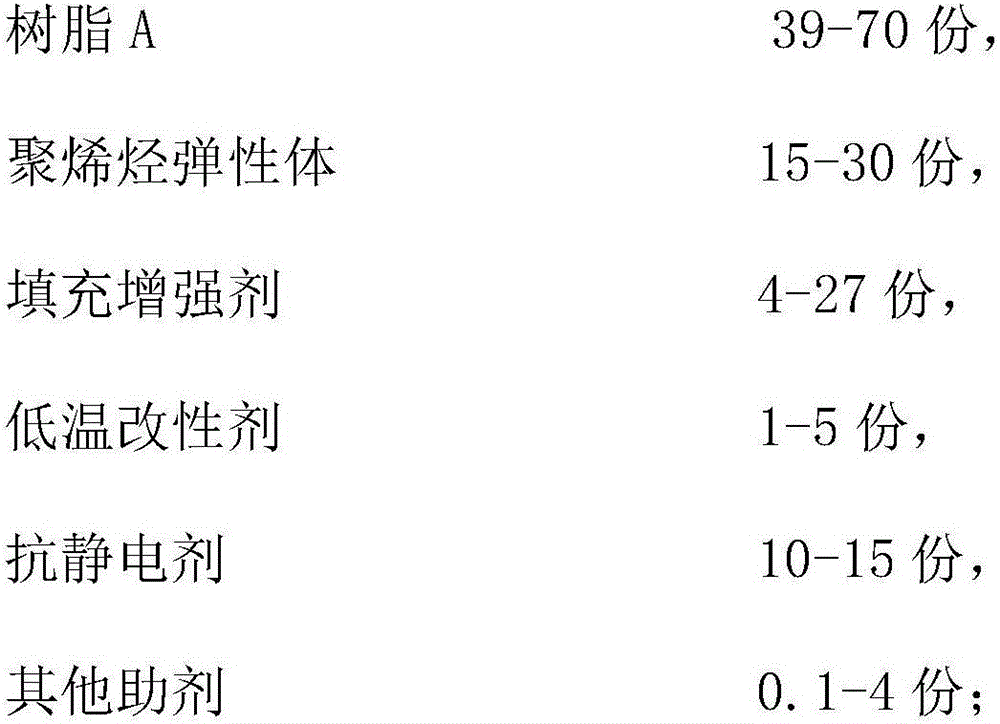

Method used

Image

Examples

Embodiment 1

[0043] A kind of ultralow temperature resistant antistatic polypropylene composition, this composition is made of the raw material that comprises following parts by weight: 69.4 parts of polypropylene resins, 15 parts of polyolefin elastomers, 4 parts of talc masterbatches (talcum powder and polypropylene resin The mass ratio is 4:1), acrylic acid-polysiloxane rubber-methyl methacrylate multi-polymer copolymer 1 part, permanent antistatic agent 10 parts, phenolic heat stabilizer 0.2 part, hindered amine light stabilizer 0.2 parts, erucamide 0.2 parts.

[0044] The preparation method of the described ultralow temperature resistant antistatic polypropylene composition comprises the steps:

[0045] (1) Add talcum powder and polypropylene resin to a high-temperature mixer, pre-mix at a temperature of 170°C, granulate and cool to obtain a filling enhancer;

[0046] (2) Mix the filling reinforcing agent, polypropylene resin, polyolefin elastomer, low-temperature modifier, antistati...

Embodiment 2

[0049] A kind of ultralow temperature resistant antistatic polypropylene composition, this composition is made of the raw material that comprises following parts by weight: 45.4 parts of polypropylene resins, 27 parts of polyolefin elastomers, 15 parts of talcum masterbatches (talcum powder and polypropylene resin The mass ratio is 4:1), acrylic acid-ethylene propylene rubber-methyl methacrylate multi-polymer copolymer 2 parts, permanent antistatic agent 10 parts, phenolic heat stabilizer 0.2 parts, hindered amine light stabilizer 0.2 parts , 0.2 parts of erucamide.

[0050] The preparation method of the described ultralow temperature resistant antistatic polypropylene composition comprises the steps:

[0051] (1) Add talcum powder and polypropylene resin to a high-temperature mixer, pre-mix at a temperature of 170°C, granulate and cool to obtain a filling enhancer;

[0052] (2) Mix the filling reinforcing agent, polypropylene resin, polyolefin elastomer, low-temperature modi...

Embodiment 3

[0055] A kind of ultralow temperature resistant antistatic polypropylene composition, this composition is made of the raw material that comprises following parts by weight: 39.4 parts of polypropylene resins, 15 parts of polyolefin elastomers, 27 parts of talcum masterbatches (talcum powder and polypropylene resin The mass ratio is 4:1), acrylic acid-ethylene propylene rubber-methyl methacrylate multi-polymer 1.5 parts, acrylic-polysiloxane rubber-methyl methacrylate multi-polymer 1.5 parts, permanent antistatic agent 15 parts, 0.2 part of phenolic heat stabilizer, 0.2 part of hindered amine light stabilizer, 0.2 part of erucamide.

[0056] The preparation method of the described ultralow temperature resistant antistatic polypropylene composition comprises the steps:

[0057] (1) Add talcum powder and polypropylene resin to a high-temperature mixer, pre-mix at a temperature of 170°C, granulate and cool to obtain a filling enhancer;

[0058] (2) Mix the filling reinforcing age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com