Multi-block branched polyethylene and preparation method thereof

A branched polyethylene, multi-block technology, applied in the field of thermoplastic elastomers, can solve the problem of high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

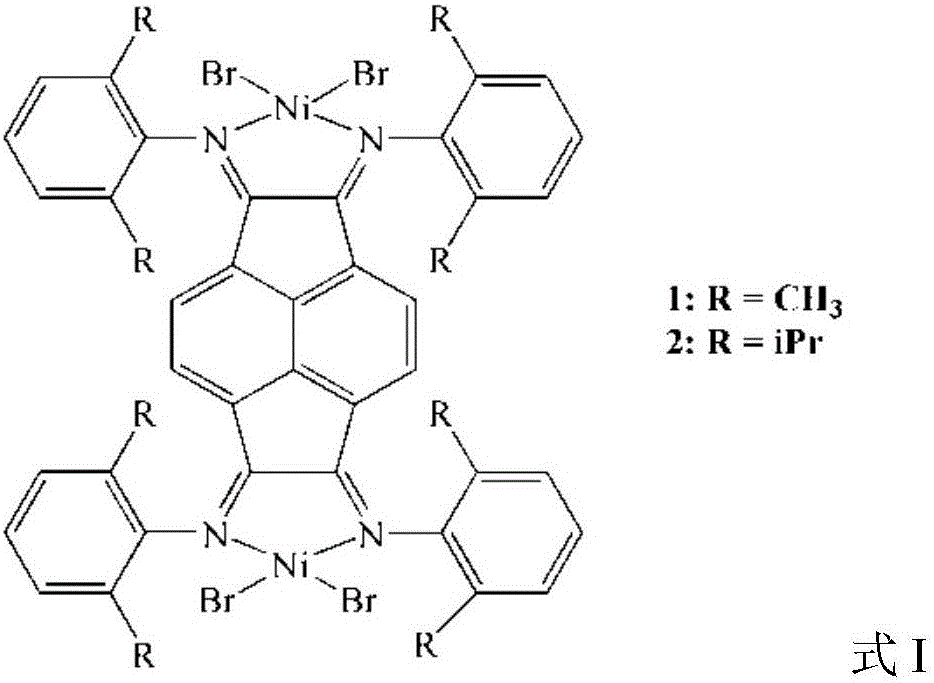

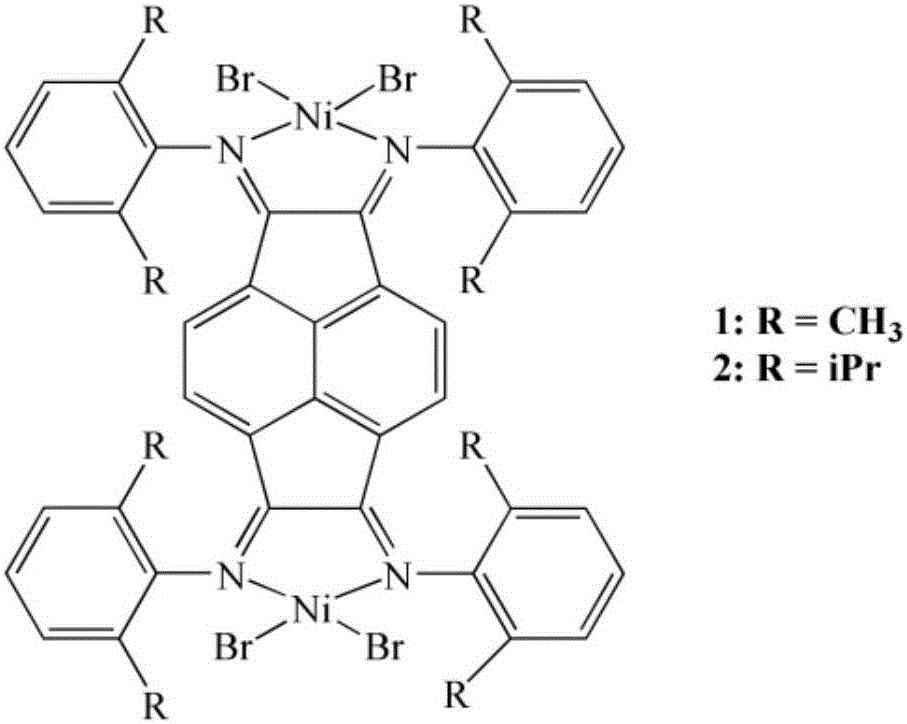

Method used

Image

Examples

Embodiment 1

[0051] Ethylene polymerization is carried out under anhydrous and oxygen-free conditions. Add 100 milliliters of n-heptane into a 200 milliliter stainless steel reaction kettle with mechanical stirring, control the temperature of the polymerization kettle to be 25° C. through jacket circulating water, and start stirring. In the polymerization kettle, add 2.0mmol cocatalyst ethyl aluminum dichloride successively [control the molar ratio between the aluminum in the ethyl aluminum dichloride and the nickel in the binuclear acenaphthylene (α-diimine) nickel catalyst to be 200], 0.2 mmol diethylzinc [control the molar ratio between the zinc in the diethylzinc and the nickel in the dinuclear acenaphthene (α-diimine) nickel catalyst to be 20], 5 μmol dinuclear acenaphthene (α-diimine) nickel catalyst 2 (R is isopropyl, dissolved in 10 ml of toluene in advance), the concentration of the catalyst in the polymerization system is 45.5 μmol / L. Feed ethylene until the pressure of the reac...

Embodiment 2

[0055] The polymerization pressure of ethylene was reduced to 0.7 MPa, and other conditions were the same as in Example 1 to obtain 18.5 grams of polymer. The catalyst activity is 3700kgPE[mol(Ni)h] -1 , the weight average molecular weight of the polymerization product is 12.6×10 4 g / mol, the polydispersity coefficient is 3.0, the glass transition temperature is -68°C, the melting point is 120.6°C, and the crystallinity is 9.2%. The tensile properties of the polymerization product were tested according to GB / T 528-2009, the tensile strength was 14.0MPa, and the elongation at break was 900%. The polymer product is stretched to 2 times of its original length at room temperature and kept for 1 minute, and then the external force is removed, and it can recover to 1.21 times of its original length within 1 minute.

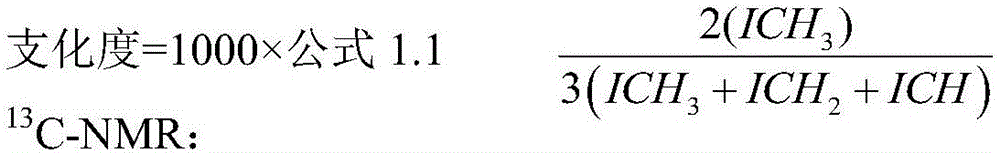

[0056] through 1 H-NMR measurement shows that the degree of branching of the polymerization product is 82.3 branched chains / 1000 carbon atoms, 49mol% of the branched c...

Embodiment 3

[0059] The polymerization pressure of ethylene was reduced to 0.4 MPa, and other conditions were the same as in Example 1 to obtain 16.3 grams of polymer. The catalyst activity is 3260kgPE[mol(Ni)h] -1 , the weight average molecular weight of the polymerization product is 11.9×10 4 g / mol, the polydispersity coefficient is 2.9, the glass transition temperature is -69°C, the melting point is 120.1°C, and the crystallinity is 8.7%. The tensile properties of the polymerization product were tested according to GB / T 528-2009, the tensile strength was 12.0MPa, and the elongation at break was 850%. The polymer product is stretched to 2 times of its original length at room temperature and maintained for 1 minute and then removed from the external force, it can recover to 1.20 times of its original length within 1 minute.

[0060] through 1 H-NMR measurement, the degree of branching of the polymerization product is 93.2 branched chains / 1000 carbon atoms, and 54.8mol% is methyl branch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com