Ternary rare earth doped YSZ thermal barrier coating material and preparation method thereof

A technology of thermal barrier coating and rare earth doping, which is applied in the field of coating materials, can solve the problems of insufficient thermal conductivity, phase stability and anti-sintering performance of thermal barrier coatings, negligence, etc., and achieve excellent anti-sintering performance , simple and precise operation, strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

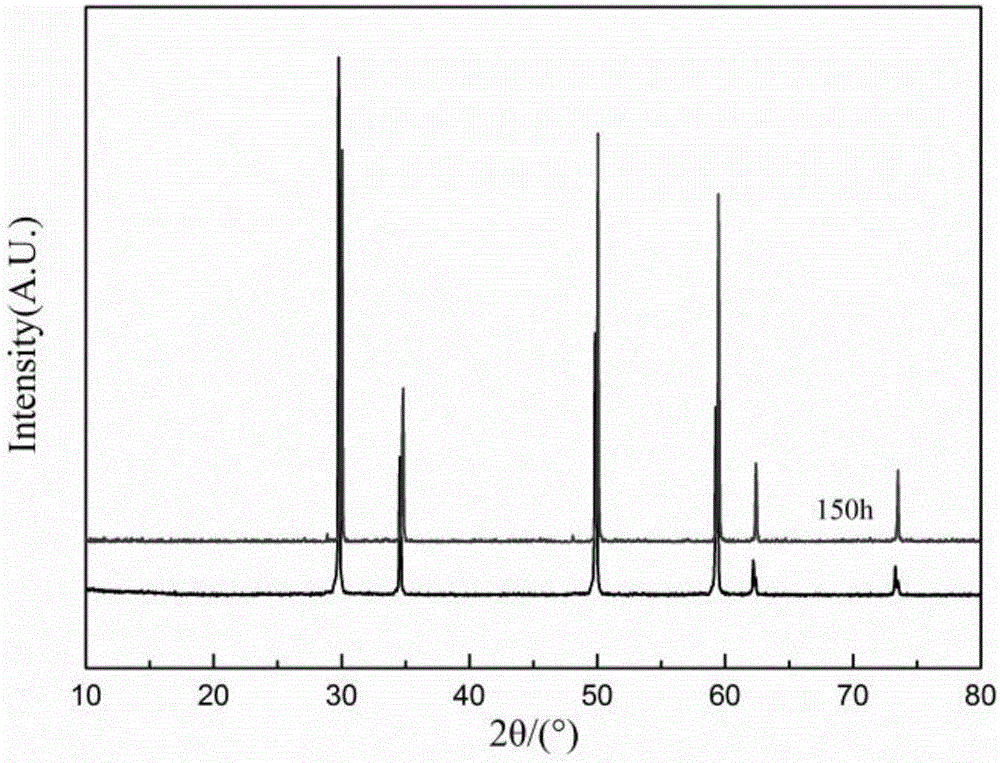

Image

Examples

Embodiment 1

[0050] 1. Add 0.1-3μm La 2 o 3 、Gd 2 o 3 , Y 2 o 3 , Yb 2 o 3 and ZrO 2 The powder raw materials are respectively loaded into different corundum crucibles, and placed in a box-type resistance furnace for 2 hours at 1000°C, and then cooled to room temperature with the furnace to remove the moisture and impurities adsorbed in the powder raw materials;

[0051] 2. Accurately weigh the required La according to the ratio 2 o 3 、Gd 2 o 3 , Y 2 o 3 , Yb 2 o 3 and ZrO 2 The quality of powder raw materials, wherein the molar ratio of each powder raw material is 0.5:1.5:1.5:4.0:92.5, and put into polyurethane ball mill, add absolute ethanol and zirconia balls, zirconia ball quality: powder raw material quality: absolute ethanol Mass = 4:1:1, resulting in a mixture;

[0052] 3. Put the above-mentioned mixture in a planetary ball mill and mechanically mill it for 3 hours at a milling speed of 350rpm / min; pour the mixed suspension into an eggplant-shaped bottle, and dry it...

Embodiment 2

[0062] 1. Add 0.1-3μm La 2 o 3 、Gd 2 o 3 , Y 2 o 3 , Yb 2 o 3 and ZrO 2 The powder raw materials are respectively loaded into different corundum crucibles, and placed in a box-type resistance furnace for 2 hours at 1000°C, and then cooled to room temperature with the furnace to remove the moisture and impurities adsorbed in the powder raw materials;

[0063] 2. Accurately weigh the required La according to the ratio 2 o 3 、Gd 2 o 3 , Y 2 o 3 , Yb 2 o 3 and ZrO 2 The quality of powder raw materials, wherein the molar ratio of each powder raw material is 1.0:2.0:2.0:4.2:90.8, and put into polyurethane ball mill, add absolute ethanol and zirconia balls, zirconia ball quality: powder raw material quality: absolute ethanol Mass = 4.5:1:1;

[0064] 3. Put the above-mentioned mixture in a planetary ball mill and mechanically mill it for 3 hours at a milling speed of 350rpm / min; pour the mixed suspension into an eggplant-shaped bottle, and dry it on a rotary evaporato...

Embodiment 3

[0073] 1. Add 0.1-3μm La 2 o 3 、Gd 2 o 3 , Y 2 o 3 , Yb 2 o 3 and ZrO 2 The powder raw materials are respectively loaded into different corundum crucibles, and placed in a box-type resistance furnace for 2 hours at 1000°C, and then cooled to room temperature with the furnace to remove the moisture and impurities adsorbed in the powder raw materials;

[0074] 2. Accurately weigh the required La according to the ratio 2 o 3 、Gd2 o 3 , Y 2 o 3 , Yb 2 o 3 and ZrO 2 The quality of powder raw materials, wherein the molar ratio of each powder raw material is 1.5:2.5:2.5:4.5:89, and put into polyurethane ball mill, add absolute ethanol and zirconia balls, zirconia ball quality: powder raw material quality: absolute ethanol Mass = 5:1:1, resulting in a mixture;

[0075] 3. Put the above-mentioned mixture in a planetary ball mill and mechanically mill it for 3 hours at a milling speed of 350rpm / min; pour the mixed suspension into an eggplant-shaped bottle, and dry it on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com