Microelectronic air pressure sensor and preparation method therefor

An air pressure sensor, microelectronics technology, applied in electrical components, piezoelectric devices/electrostrictive devices, fluid pressure measurement using capacitance changes, etc., can solve problems such as poor reliability, difficult packaging, etc. The effect of short time and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

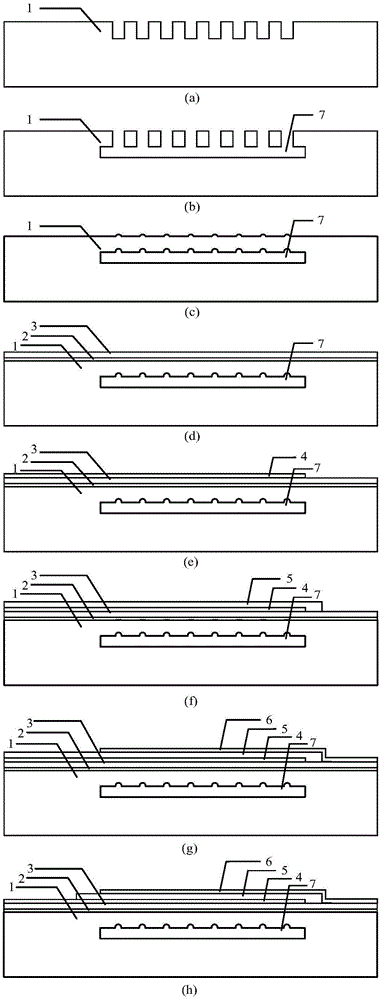

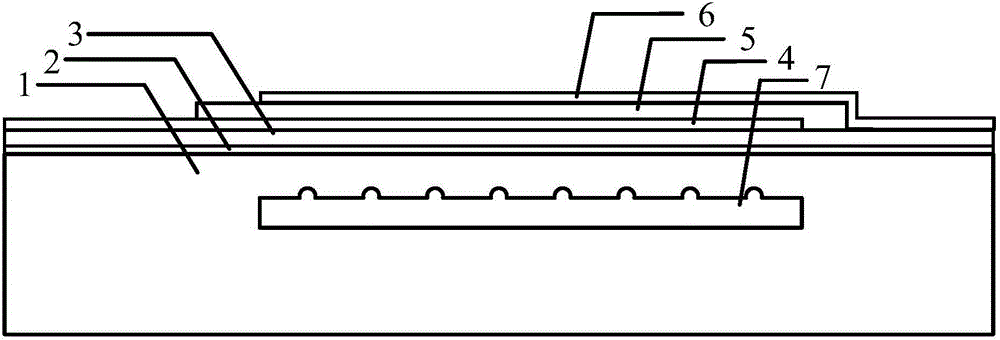

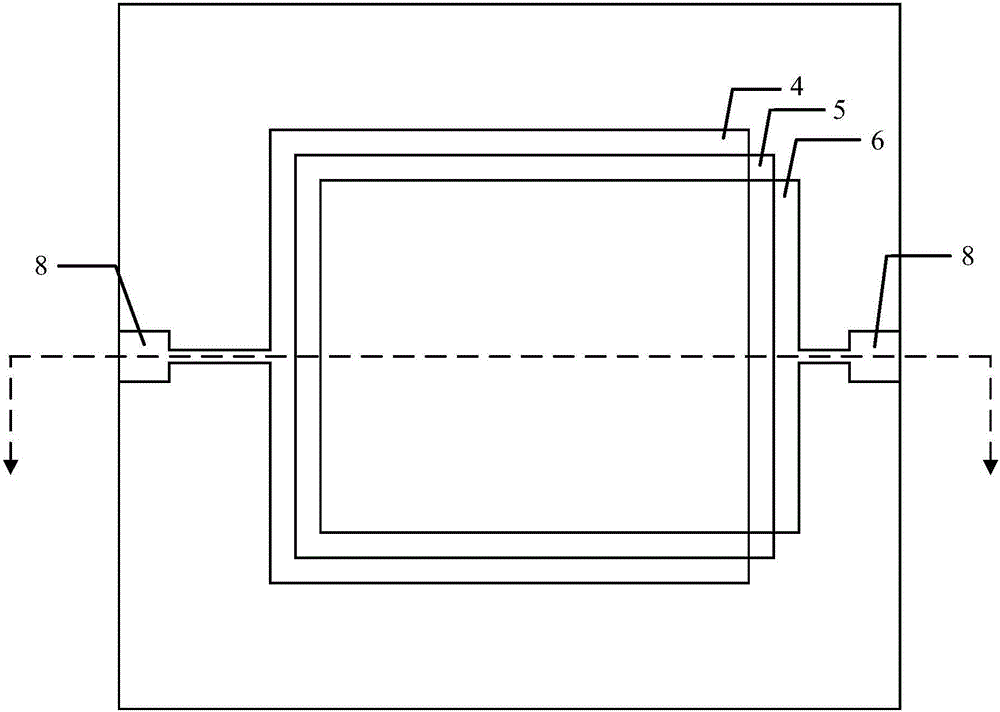

[0028] Such as Figure 1 to Figure 3 As shown, the microelectronic air pressure sensor provided by the present invention is prepared through the following steps:

[0029] (A) N-type (100) single crystal silicon is used as the substrate 1, and a shallow groove of 1-10 μm is etched on the single crystal silicon substrate 1 through an anisotropic reactive ion etching RIE process;

[0030] (B) While protecting the sidewalls of the shallow grooves of the single crystal silicon substrate 1, isotropic etching is performed on the single crystal silicon substrate to prepare for the next epitaxial single crystal silicon cavity sealing process;

[0031] (C) Epitaxially grow single crystal silicon, forming a sealed cavity 7 inside the single crystal silicon substrate, the cavity height is about 5μm;

[0032] (D) Sequentially grow silicon oxide 2 and silicon nitride 3 on the upper surface of the single crystal silicon substrate 1, and form contact holes by photolithography and etching;

[0033] (E)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com