Welding device used for aluminum material machining

A welding device and aluminum material technology, which is applied in the field of aluminum material processing, can solve the problems of easy oxidation, high power consumption, burn-through and collapse, etc., and achieve the effects of improving welding strength, improving utilization efficiency and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

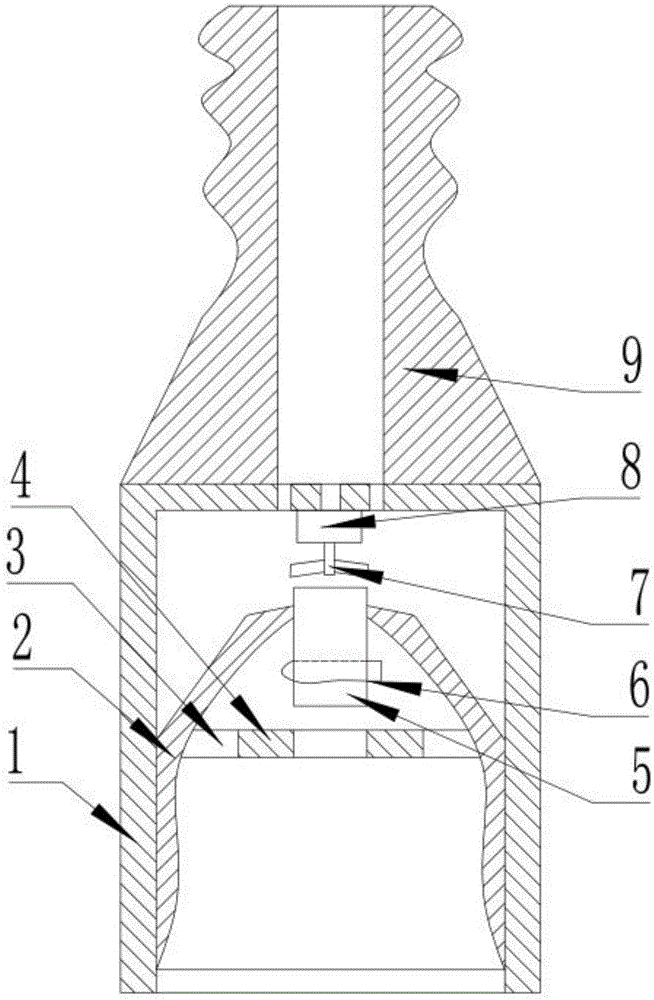

[0022] Such as figure 1 As shown, a welding device for processing aluminum materials, the welding device is mainly composed of a casing 1, an acoustic lens 2, a vibrating membrane 3, a moving coil 4, a magnetic core 5, a fixed coil 6, and a handle 9; the casing 1 is Cylindrical with one end open, the sealed end of the housing 1 is connected to the handle 9; the acoustic wave lens 2 is bell-shaped, the acoustic wave lens 2 is arranged inside the housing 1, and the opening direction of the acoustic wave lens 2 is the same as the opening direction of the housing 1; the vibrating membrane 3 is a circular sheet shape, the vibrating membrane 3 is arranged inside the acoustic wave lens 2, and the moving coil 4 is connected to the vibrating membrane 3; the magnetic core 5 is arranged at the bottom of the acoustic wave lens 2, and the fixed coil 6 is arranged on the outer periphery of the magnetic core 5; The axes of the coil 6, the magnetic core 5, the vibrating membrane 3 and the mov...

Embodiment 2

[0025] On the basis of Embodiment 1, this embodiment discloses a preferred structure of a welding device for processing aluminum materials, such as figure 1 As shown, the welding device is also provided with a cooling device. The cooling device is mainly composed of an impeller 7 and a motor 8 . The cooling device can reduce the temperature of the equipment and ensure the normal operation of the equipment.

[0026] Further, the inside of the handle 9 is provided with a cable connection through hole.

[0027] Further, each point on the inner wall of the acoustic wave lens 2 is symmetrical to the vertical line connecting each point of the vibrating membrane 3 and the preset processing point with respect to this point; the material of the acoustic wave lens 2 is quartz. The acoustic wave lens 2 converges the ultrasonic waves emitted by the vibrating membrane 3, which greatly increases the energy density of the working surface; the high hardness of quartz can reflect high-frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com