Onion paste and preparation method thereof

A technology of onion paste and onion, which is applied in the field of food processing, can solve the problems of waste of resources and low utilization rate of onion, and achieve the effect of increasing utilization rate, good solubility and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

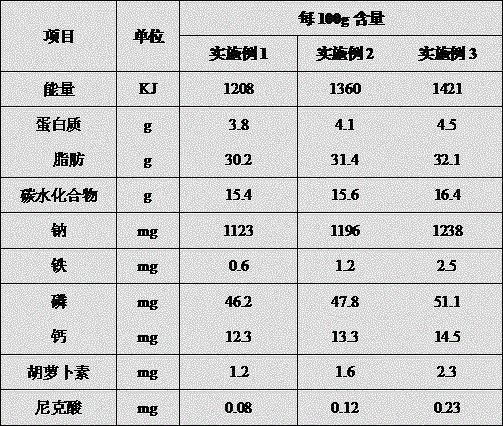

Image

Examples

Embodiment 1

[0027] An onion sauce mainly includes the following raw materials, 80kg of onion, 5kg of citric acid, 5kg of hydrolase, and appropriate amount of seasoning.

[0028] Above-mentioned condiment is table salt, white sugar, monosodium glutamate, pepper powder, Chinese prickly ash and five-spice powder.

[0029] The above-mentioned hydrolase is one of amylase, cellulase, protease and lysozyme.

[0030] A preparation method of onion paste, comprising the following steps:

[0031] (1) Selection of raw materials: select fresh onions without variegated and mildew, and weigh 80kg by weight for later use;

[0032] (2) Raw material pretreatment: remove the onion skin, root disc and fiber old skin, and then cut into discs with a thickness of 0.1cm;

[0033] (3) Crushing: Put the chopped onions in step (2) into the crusher, adjust the aperture of the crushing sieve to 0.5cm to crush the onions;

[0034] (4) Primary rubber mill: Transfer the crushed onions in step (3) to a rubber mill, ad...

Embodiment 2

[0044] An onion sauce mainly includes the following raw materials, 90kg of onion, 8kg of citric acid, 8kg of hydrolase, and appropriate amount of seasoning.

[0045] Above-mentioned condiment is table salt, white sugar, monosodium glutamate, pepper powder, Chinese prickly ash and five-spice powder.

[0046] The above-mentioned hydrolase is one of amylase, cellulase, protease and lysozyme.

[0047] A preparation method of onion paste, comprising the following steps:

[0048] (1) Selection of raw materials: select fresh onions without variegated and mildew, and weigh 90kg by weight for later use;

[0049] (2) Pretreatment of raw materials: remove the onion skin, root disc and old fiber skin, and then cut into discs with a thickness of 0.3cm;

[0050] (3) Crushing: Put the chopped onions in step (2) into the crusher, adjust the aperture of the crushing sieve to 0.8cm to crush the onions;

[0051] (4) Primary rubber mill: Transfer the crushed onions in step (3) to the rubber mi...

Embodiment 3

[0061] An onion sauce mainly includes the following raw materials, 100kg of onions, 10kg of citric acid, 10kg of hydrolase, and appropriate amount of seasonings.

[0062] Above-mentioned condiment is table salt, white sugar, monosodium glutamate, pepper powder, Chinese prickly ash and five-spice powder.

[0063] The above-mentioned hydrolase is one of amylase, cellulase, protease and lysozyme.

[0064] A preparation method of onion paste, comprising the following steps:

[0065] (1) Raw material selection: select fresh onions without variegated and mildew, and weigh 100kg by weight for later use;

[0066] (2) Raw material pretreatment: remove the onion skin, root disc and old fiber skin, and then cut into discs with a thickness of 0.5cm;

[0067] (3) Crushing: put the chopped onions in step (2) into the crusher, adjust the crushing sieve aperture to 1cm to crush the onions;

[0068] (4) Primary rubber mill: transfer the crushed onions in step (3) to the rubber mill, adjust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com