Disposable degradable chopstick and production method thereof

A technology for disposable chopsticks, applied in the field of disposable degradable chopsticks and their preparation, can solve the problems of high processing cost, uncleanness, consumption of forest land, etc., and achieve the effects of improving comprehensive performance, strengthening extraction, and prolonging shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The invention provides a disposable degradable chopsticks, comprising the following raw materials in parts by weight: 20 parts of tapioca starch, 20 parts of peanut shell, 20 parts of almond shell, 40 parts of sisal fiber, 27 parts of banana fiber, 40 parts of edible gum, 10 parts of molding powder, 5 parts of clay, 0.2 parts of cactus, 0.3 parts of cumin, 0.2 parts of ginkgo, 0.2 parts of cardamom and 0.3 parts of tea leaves;

[0030] Wherein, the edible gum is a mixture of locust bean gum, xanthan gum and gelatin with a mass ratio of 2:1:3;

[0031] The molding powder is melamine formaldehyde molding powder.

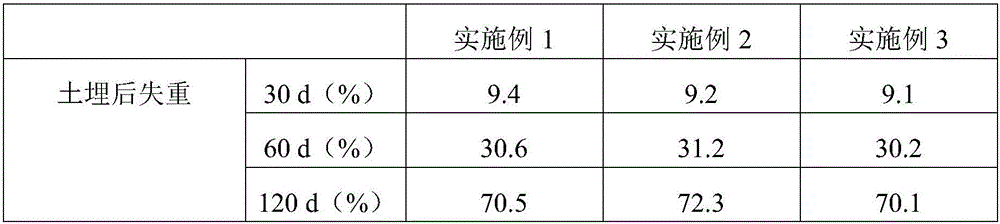

[0032] Biodegradable tapioca starch, peanut shells, almond shells, sisal fibers, and banana fibers are used to prepare disposable degradable chopsticks. The wear-resistant and corrosion-resistant properties of sisal fibers are comprehensively utilized, as well as the light weight and gloss of banana fibers. The addition of edible glue and molding powder can eff...

Embodiment 2

[0043] The invention provides a disposable degradable chopsticks, comprising the following raw materials in parts by weight: 30 parts of tapioca starch, 10 parts of peanut shell, 30 parts of almond shell, 35 parts of sisal fiber, 35 parts of banana fiber, 30 parts of edible gum, 15 parts of molding powder, 2 parts of pottery clay, 0.3 part of cactus, 0.1 part of cumin, 0.4 part of ginkgo, 0.1 part of cardamom and 0.4 part of tea;

[0044] Wherein, the edible gum is a mixture of locust bean gum, xanthan gum and gelatin with a mass ratio of 2:1:3;

[0045] The molding powder is melamine formaldehyde molding powder.

[0046] Biodegradable tapioca starch, peanut shells, almond shells, sisal fibers, and banana fibers are used to prepare disposable degradable chopsticks. The wear-resistant and corrosion-resistant properties of sisal fibers are comprehensively utilized, as well as the light weight and gloss of banana fibers. The addition of edible glue and molding powder can effecti...

Embodiment 3

[0057] The invention provides a disposable degradable chopsticks, comprising the following raw materials in parts by weight: 25 parts of tapioca starch, 15 parts of peanut shell, 25 parts of almond shell, 37 parts of sisal fiber, 30 parts of banana fiber, 35 parts of edible gum, 13 parts of molding powder, 4 parts of clay, 0.25 parts of cactus, 0.2 parts of cumin, 0.3 parts of ginkgo, 0.15 parts of cardamom and 0.35 parts of tea leaves;

[0058] Wherein, the edible gum is a mixture of locust bean gum, xanthan gum and gelatin with a mass ratio of 2:1:3;

[0059] The molding powder is melamine formaldehyde molding powder.

[0060] Biodegradable tapioca starch, peanut shells, almond shells, sisal fibers, and banana fibers are used to prepare disposable degradable chopsticks. The wear-resistant and corrosion-resistant properties of sisal fibers are comprehensively utilized, as well as the light weight and gloss of banana fibers. The addition of edible glue and molding powder can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com