High thermal conductivity graphene composite interface material and preparing method thereof

A technology of high thermal conductivity graphite and interface materials, which is applied in the field of thermal conductivity materials, can solve problems such as difficulty in greatly improving thermal conductivity, and achieve the effects of good mechanical strength performance, improved dispersion, and good compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

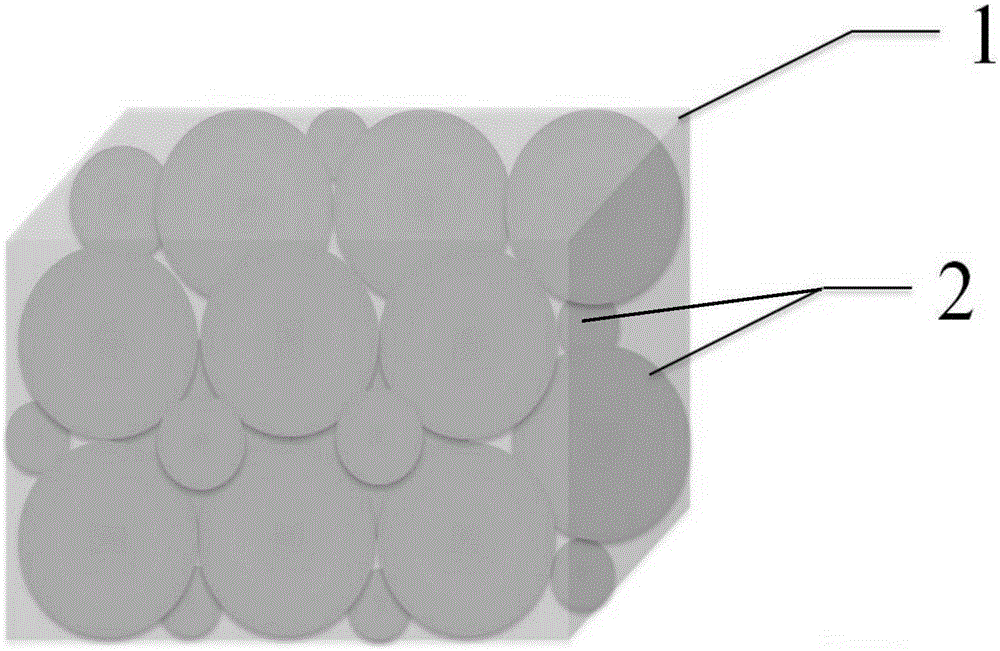

Image

Examples

Embodiment 1

[0076] 1. Prepare the first mixture

[0077] Dry methacrylate siloxane, spherical alumina powder, spherical zinc oxide powder and polyhedral boron nitride powder at 110°C for 20 minutes, then cool to room temperature;

[0078] Weigh dry vinyl polysiloxane 3g, methyl acrylate siloxane 2g, spherical aluminum oxide and spherical zinc oxide mixed powder 90g (D50=3.0-100μm, the mass ratio of spherical aluminum oxide and spherical zinc oxide 7:3), polyhedral boron nitride powder 1g (D50=0.4-1.0μm), graphene powder 0.5g (sheet structure, thickness 2-10nm, sheet length 3-50μm,) placed in a mixer , stirring at a speed of 30r / min for 60min to prepare the first mixture.

[0079] 2. Preparation of the second mixture

[0080] Mix and stir the aluminate coupling agent and polyethylene glycol 200 evenly to prepare an auxiliary agent solution with a concentration of 10g / L. Weigh 2.0g of the auxiliary agent solution and add it to the first mixture, at a speed of 60r / min Stir for 20 minutes ...

Embodiment 2

[0087] 1. Prepare the first mixture

[0088] Dry styryl polysiloxane, spherical zinc oxide powder, spherical boron nitride powder and polyhedral aluminum nitride powder at 90°C for 60 minutes, then cool to room temperature;

[0089] Take by weighing dry vinyl polysiloxane 6g, styrene-based polysiloxane 4g, the mixed powder 70g (D50=0.2-50 μ m of spherical zinc oxide and spherical boron nitride, the mass of spherical zinc oxide and spherical boron nitride The ratio is 6:4), polyhedral aluminum nitride powder 5g (D50=0.2-0.6μm), graphene powder 1g (sheet structure, thickness 2-10nm, sheet length 3-50μm,) placed in the mixer , stirring at a speed of 60r / min for 20min to prepare the first mixture.

[0090] 2. Preparation of the second mixture

[0091] Mix and stir the titanate coupling agent and polyethylene glycol 400 evenly to prepare an auxiliary agent solution with a concentration of 10g / L; weigh 0.5g of the auxiliary agent solution and add it to the first mixture, at a spee...

Embodiment 3

[0098] 1. Prepare the first mixture

[0099] Spherical alumina powder, spherical aluminum nitride powder, polyhedral alumina powder and graphene powder were dried at 100°C for 30 minutes, then cooled to room temperature;

[0100] Weigh 8g of methyl vinyl polysiloxane, 80g of dry mixed powder of spherical alumina and spherical aluminum nitride (D50=1-70μm, the mass ratio of spherical alumina and spherical aluminum nitride is 7:3), Polyhedral alumina powder 3g (D50=0.2-1.0μm), graphene powder 2g (sheet structure, thickness 2-10nm, sheet length 3-50μm,) placed in a mixer, at a speed of 45r / min The mixture was stirred for 30 minutes to obtain the first mixture.

[0101] 2. Preparation of the second mixture

[0102] Mix and stir the silane coupling agent and polyethylene glycol 200 evenly to prepare an additive solution with a concentration of 10g / L; weigh 1.0g of the additive solution and add it to the first mixture, and stir at a speed of 45r / min After 40 minutes, the second p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com