Treatment method and treatment system for salt-containing water

The technology of a water treatment system and treatment method is applied in the salt water treatment system and the treatment field of salt water, which can solve the problems of increasing the consumption of industrial sodium chloride and restricting the economy of the wastewater treatment process, so as to reduce the comprehensive treatment cost and realize the The effect of zero liquid discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

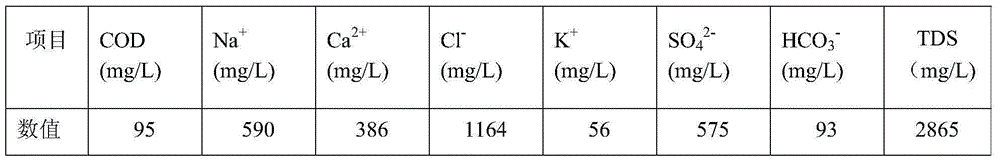

[0132] This example is used to illustrate the brine treatment method of the present invention.

[0133] (1) Supply the synthetic saline wastewater described in Table 1 to the lime softening and clarification unit for lime softening and clarification treatment, wherein the lime softening and clarification treatment method includes: adding 90 mg / L of hydrogen to the synthetic saline wastewater Calcium oxide and 694 mg / L sodium carbonate reacted for 30 minutes and then stood for clarification for 60 minutes to obtain lime-softened effluent and sludge, which were supplied to the desludge treatment unit for desludge treatment.

[0134] (2) Supply the lime softening effluent from the lime softening and clarification unit to the solid-liquid separation unit for solid-liquid separation, wherein the method for solid-liquid separation is: adjust the pH value of the lime softening effluent to 6.5 with hydrochloric acid, and then Use a security filter with a filtration precision of 5 μm t...

Embodiment 2

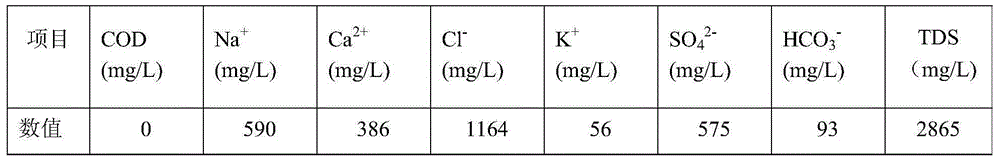

[0149] This example is used to illustrate the brine treatment method of the present invention.

[0150] (1) Supply the synthetic saline wastewater described in Table 2 to the lime softening and clarification unit for lime softening and clarification treatment, wherein the lime softening and clarification treatment method includes: adding 90 mg / L of hydrogen to the synthetic saline wastewater Calcium oxide and 694mg / L of sodium carbonate reacted for 30 minutes and then stood for clarification for 180 minutes to obtain lime-softened effluent and sludge. The sludge was supplied to the desludge treatment unit for desludge treatment.

[0151] (2) Supply the lime softened effluent from the lime softening and clarification unit to the strong acid cation exchange resin softening unit for softening treatment with strong acid cation exchange resin, wherein, the method of softening treatment with strong acid cation exchange resin includes: using strong acid styrene Cation exchange resin (N...

Embodiment 3

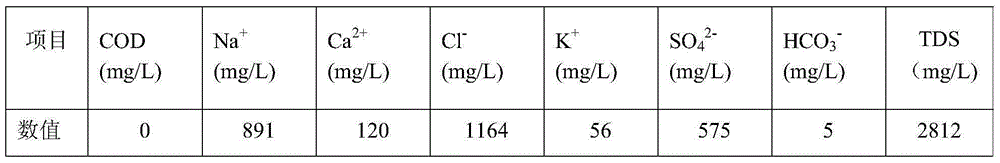

[0162] This example is used to illustrate the brine treatment method of the present invention.

[0163] (1) supply the synthetic saline waste water described in table 3 to the softening unit of strong acid cation exchange resin and carry out softening treatment with strong acid cation exchange resin, wherein, the method for softening treatment with strong acid cation exchange resin comprises: using strong acid styrene series cation Exchange resin (chemical plant of Nankai University, trade mark 001×7) is processed synthetic saline waste water, and the residence time of strong acid cation exchange resin treatment is 4 minutes, obtains the hardness of calcium carbonate meter and is the strong acid cation exchange softening of 22.5mg / L. out of water.

[0164] (2) Supply the strong acid cation exchange softening effluent from the strong acid cation exchange resin softening unit to the weak acid cation exchange resin softening unit and carry out softening treatment with weak acid c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen consumption | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com