Manufacturing method of polyethylene colored fibers with ultrahigh molecular weight

An ultra-high molecular weight, colored fiber technology, applied in the field of synthetic fibers, can solve the problems of high cost, cumbersome and complicated process, unrecyclable, etc., and achieve the effect of light, thin and soft texture, good color uniformity, and rich color varieties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

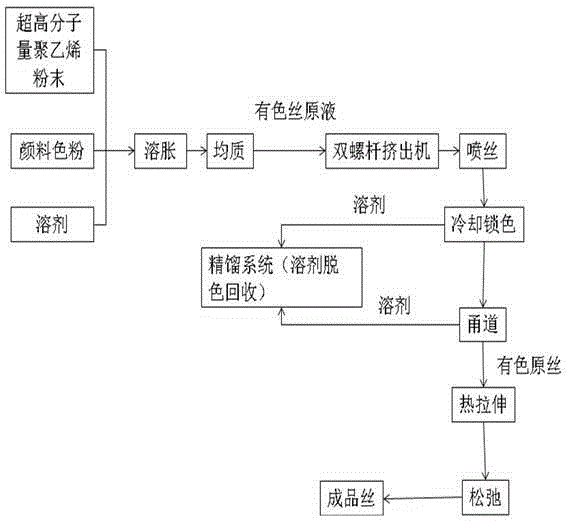

[0030] Embodiment 1: as figure 1 As shown, carbon black pigment with a particle size of 80nm, ultra-high molecular weight polyethylene powder, and decahydronaphthalene solvent are added to a swelling tank with a stirring device at a mass ratio of 0.5:13:87 for swelling for 3 hours, and the swelling temperature is 94.2°C, and then Enter the homogenizing kettle with stirring device and back-beating device for homogenization for 1 hour, the homogenization temperature is 40.7°C, and then enter the screw extruder through saturated feeding mode for further extrusion, shearing, and full dissolution. The temperature in the 1-14 zone of the screw is 98°C, 125°C, 138°C, 154°C, 155°C, 168°C, 180°C, 168°C, 150°C, 144°C, 138°C, 138°C, 129°C, 125°C, the spinning solution is sprayed at 1600D / 1380f After the wire sheet is spun, it enters the cooling zone where the flowing medium is nitrogen, the temperature of the cooling zone is 115°C, the length of the cooling zone is 50cm, and the air velo...

Embodiment 2

[0031] Example 2: Add yellow pigment with a particle size of 100nm, ultra-high molecular weight polyethylene powder, and decahydronaphthalene solvent into a swelling kettle for swelling for 3 hours at a mass ratio of 1.3:13:87. After massaging for 1 hour, the homogenization temperature is 60°C, and then enters the screw extruder through saturated feeding method, further extruding and shearing, and fully dissolves. °C, 165°C, 178°C, 168°C, 150°C, 144°C, 138°C, 138°C, 129°C, 125°C, the spinning solution is spun through a 400D / 230f spinneret and enters the cooling zone, the temperature of the cooling zone 110°C, cooling length 45cm, air velocity 90m 3 / h, the nitrogen flow temperature in the tunnel is 80°C, and the air velocity is 60m 3 / h. The rectification temperature is 115°C, the tower top pressure is 6.7kPa, the tower top condensation temperature is 35°C, and the reflux ratio is 0.13. The tow enters the pre-drawing zone, the pre-drawing temperature is 118°C, the draw rati...

Embodiment 3

[0032] Example 3: Red pigment with a particle size of 90nm, ultra-high molecular weight polyethylene powder, and decahydronaphthalene solvent were added to the swelling kettle for swelling at a mass ratio of 1:13:87, and the swelling temperature was 98.5°C. After massaging for 1 hour, the homogenization temperature is 60°C, and then enters the screw extruder through saturated feeding method, further extruding and shearing, and fully dissolves. °C, 163°C, 175°C, 168°C, 150°C, 145°C, 135°C, 135°C, 129°C, 125°C, the spinning solution enters the cooling zone after being spun through a 40D / 30f spinneret, the temperature of the cooling zone 105°C, cooling length 30mm, air velocity 85m 3 / h, the nitrogen flow temperature in the tunnel is 75°C, and the air velocity is 60m 3 / h, the rectification temperature is 123°C, the tower top pressure is 7.2kPa, the tower top condensation temperature is 30°C, and the reflux ratio is 0.27. The tow enters the pre-drawing zone with a pre-drawing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com