Method for improving performance of epoxy resin plating of neodymium iron boron permanent magnet

An epoxy resin, permanent magnet technology, applied in coating, electrophoretic plating, electrolytic coating, etc., can solve the problems of low efficiency, high cost, poor operability, etc., achieve low material and labor cost, low production cost, durable Corrosion performance and the effect of improving the bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

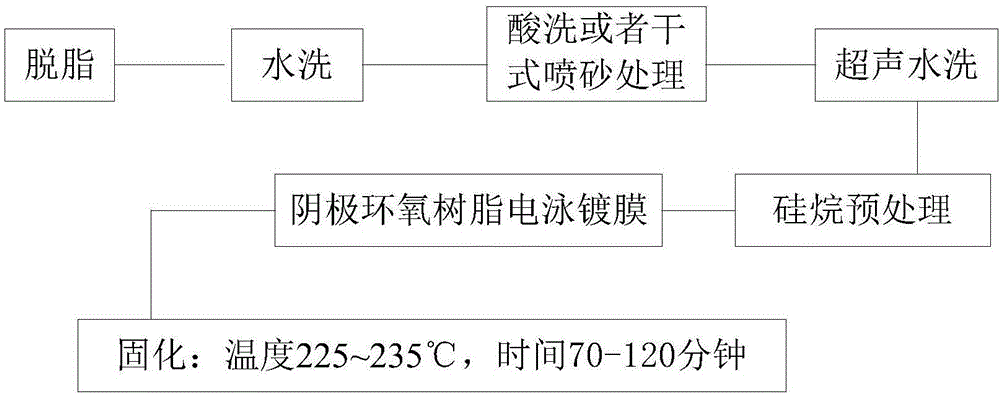

[0043] S101. Pretreatment: the NdFeB permanent magnet is degreased, washed with water, pickled and ultrasonically washed in order to remove the oxide layer on the surface of the NdFeB permanent magnet;

[0044] S102, silane pretreatment: perform silane pretreatment on the pretreated NdFeB permanent magnet to form a silane conversion film on the surface, and the silane solution includes: YL-701 nanometer phosphorus-free coating agent and YL-702 accelerator; The concentration of the YL-701 nanometer phosphorus-free coating agent is 20ml / L; the concentration of the YL-702 accelerator is 10ml / L, and the silane pretreatment conditions: temperature: normal temperature, time: 100 seconds;

[0045] S103, cathodic epoxy resin electrophoretic coating: the NdFeB permanent magnet after silane pretreatment is subjected to cathodic epoxy electrophoretic coating to obtain a NdFeB permanent magnet coated with an epoxy resin film; the cathode epoxy The electrophoretic paint solution of the res...

Embodiment 2

[0048] S101. Pretreatment: the NdFeB permanent magnet is degreased, washed with water, pickled and ultrasonically washed in order to remove the oxide layer on the surface of the NdFeB permanent magnet;

[0049] S102, silane pretreatment: perform silane pretreatment on the pretreated NdFeB permanent magnet to form a silane conversion film on the surface, and the silane solution includes: YL-701 nanometer phosphorus-free coating agent and YL-702 accelerator; The concentration of the YL-701 nano-phosphorus-free film agent is 21ml / L; the concentration of the YL-702 accelerator is 11ml / L, silane pretreatment conditions: temperature: normal temperature, time: 60 seconds;

[0050] S103, cathodic epoxy resin electrophoretic coating: the NdFeB permanent magnet after silane pretreatment is subjected to cathodic epoxy electrophoretic coating to obtain a NdFeB permanent magnet coated with an epoxy resin film; the cathode epoxy The electrophoretic paint solution of the resin electrophoreti...

Embodiment 3

[0053] S101. Pretreatment: The NdFeB permanent magnets are sequentially degreased, washed, dry sandblasting and ultrasonic washing to remove the oxide layer on the surface of the NdFeB permanent magnets. The specific steps of the dry sandblasting are: Put the dried NdFeB permanent magnet into a fully enclosed dry sandblasting machine, add sand, and sandblast; ultrasonically wash the NdFeB permanent magnet after sandblasting;

[0054] S102, silane pretreatment: perform silane pretreatment on the pretreated NdFeB permanent magnet to form a silane conversion film on the surface, and the silane solution includes: YL-701 nanometer phosphorus-free coating agent and YL-702 accelerator; The concentration of the YL-701 nano-phosphorus-free film agent is 19ml / L; the concentration of the YL-702 accelerator is 9ml / L, silane pretreatment conditions: temperature: normal temperature, time: 180 seconds;

[0055] S103, cathodic epoxy resin electrophoretic coating: the NdFeB permanent magnet af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com