Tool for quartz wafer arranging machine

A technology of quartz wafers and chip arranging machines, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as scattered wafer arrangement, and achieve the effect of weakening the influence of magnetic force, avoiding mutual friction, and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0028] The invention discloses a tooling for a quartz wafer stacker, which includes a tray and a carrier plate.

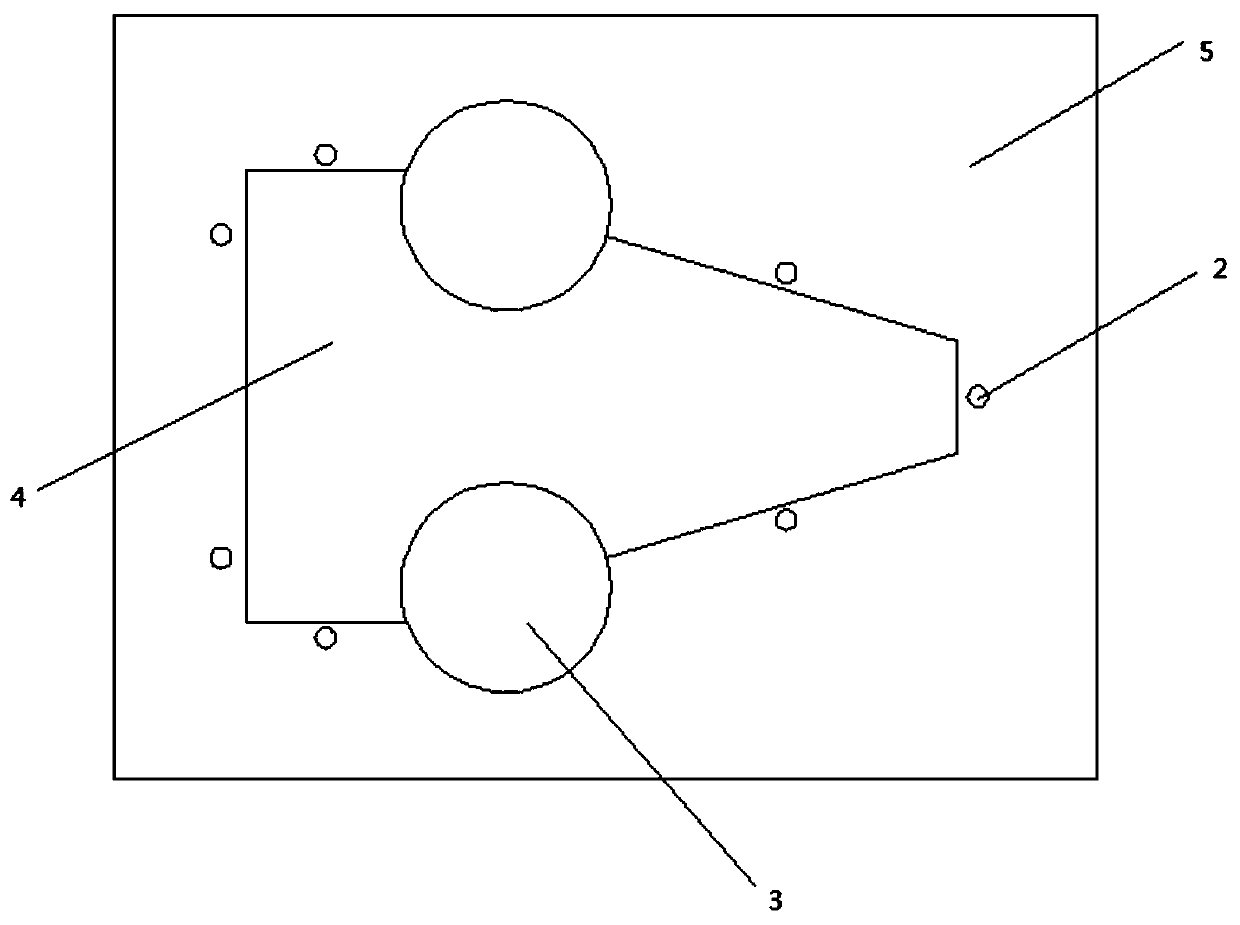

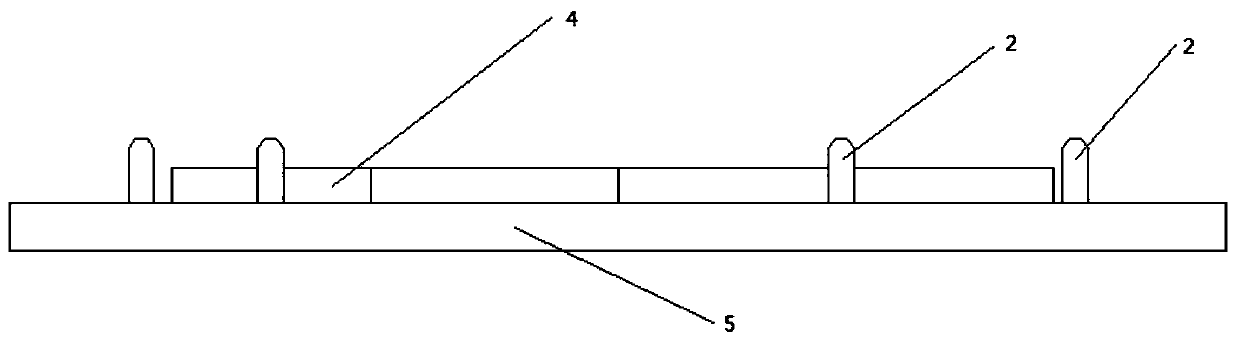

[0029] Such as figure 1 , figure 2 and image 3 , the tray includes an upper disc 4 and a lower disc 5, the lower disc 5 is rectangular, the lower disc 5 is provided with two circular holes A3, and the two circular holes A3 are symmetrical to the axis of the lower disc 5, the carrier disc 6 includes a rectangular portion and an isosceles trapezoidal portion, the bottom of the isosceles trapezoidal portion coincides with one long side of the rectangular portion, the axis of the isosceles trapezoidal portion coincides with the axis of the lower disc 5, and the carrier disc 6 is provided with Wafer placement slot 1, the profile of the upper disc 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com