Multifunctional graphene/polymer masterbatch and preparation method thereof

A graphene and polymer technology, applied in the field of multifunctional graphene/polymer masterbatch and its preparation, can solve the thermal stability and fire safety performance impact of polymer materials, can not fully display the characteristics of graphene, graphene ratio Surface area reduction and other issues, to achieve the effect of improving thermal stability and flame retardant performance, changing mechanical properties and flame retardant performance, and improving hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

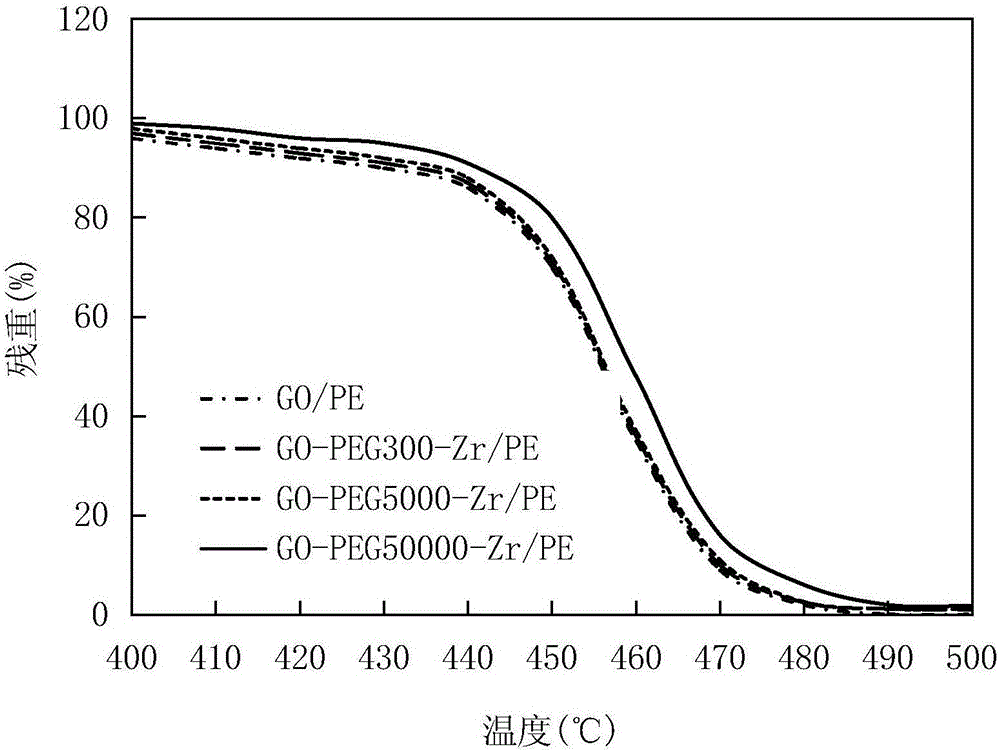

Embodiment 1

[0037] Preparation of graphene oxide: Using the Hummer method, add 4g graphite powder to a 250mL beaker, add 2g NaNO to it under the condition of ice water bath 3 After adding 100 mL of 98% H 2 SO 4 And stir well; slowly add 12gKMnO 4, keep the temperature of the solution above 20°C and maintain this condition for 5 minutes, then remove the ice-water bath and heat to 35°C, and maintain this condition for 30 minutes; add 150mL of water, and stir for 15 minutes, the temperature will rise to about 98°C; continue to add 150mL of 60°C 3% hydrogen peroxide, centrifuge the treated liquid for 30 minutes; wash the residue with hot water until the pH of the upper suspension is about 7; disperse the obtained powder in water for 15 minutes, and filter the black residue A homogeneous suspension was obtained afterward; graphene oxide (referred to as GO) was obtained after the suspension was lyophilized.

[0038] Graphene graft polymer B: Weigh 2g of GO synthesized above and disperse it i...

Embodiment 2

[0042] The preparation method of graphene oxide and GO-PEG5000 is the same as Example 1; the preparation method of GO-PEG5000-Zr is the same as Example 1, but the quality of zirconium oxychloride is adjusted, and the quality of zirconium oxychloride is the same as that of GO / metal The mass molar ratio is calculated as 1g:0.1mol.

[0043] The masterbatch preparation of GO-PEG5000-Zr / PE is the same as in Example 1.

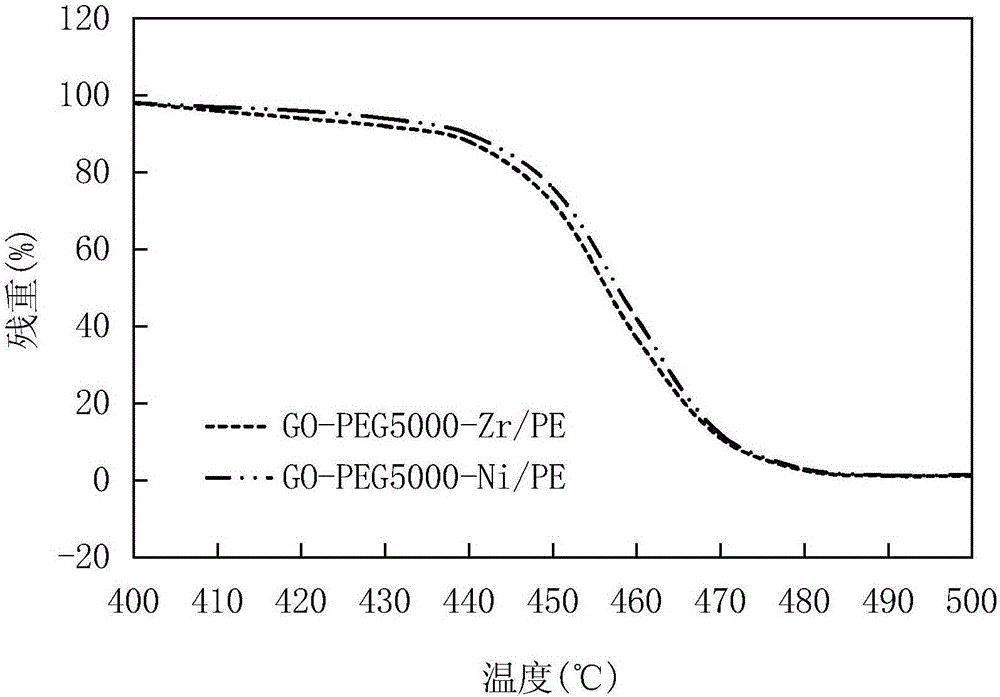

Embodiment 3

[0045] The preparation method of graphene oxide and GO-PEG5000 is the same as embodiment 1;

[0046] Graphene-loaded transition metals: Dissolve nickel chloride in water and add it to 1g GO-PEG5000 ultrasonically uniformly dispersed aqueous solution. The mass of nickel chloride is calculated by using the mass molar ratio of GO / metal as 1g:0.05mol, and mechanically stirred For 2 hours, under stirring, ammonia water was added dropwise therein until the pH was 9-10, and then placed in a reaction kettle at 200° C. for 5 hours, and after suction filtration and water washing for 3-5 times, vacuum-dried to obtain multifunctional graphene (denoted as GO-PEG5000-Ni).

[0047] Preparation of masterbatch: Mix 0.2g PE and 0.2g GO-PEG300-Ni in 100mL N,N-dimethylformamide under ultrasonic dispersion and mechanical stirring, then add 0.02g melted into liquid Polyethylene wax, and 0.004g antioxidant 1010 to obtain a mixture, continuous ultrasonic dispersion and mechanical stirring to make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com