Happy farmhouse wastewater treatment device and method

A sewage treatment device and farm technology, applied in the direction of biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult water quality, high nitrogen and phosphorus content, high oil content, etc. problems, to achieve the effects of high carbon, phosphorus and nitrogen removal efficiency, high activity, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

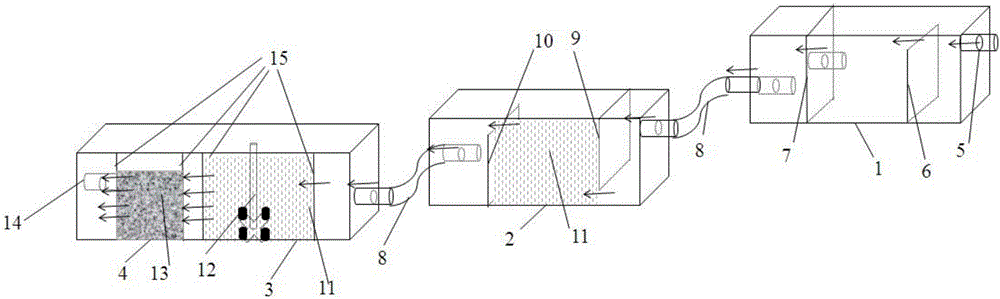

[0053] In this example, using figure 1 Processing device shown.

[0054] The farmhouse catering wastewater collected through the pipe network flows into the oil separation sedimentation tank 1 by itself, and the suspended solids and oil in the sewage are initially separated by natural flotation, so as to prevent it from clogging the subsequent treatment unit and reduce the load of subsequent treatment, and then pass through The pretreated sewage enters the aerobic tank 2, and a combined film-hanging filler is set in the aerobic tank, and microorganisms are inoculated. The growth provides strong conditions and increases its contact area with the sewage. The bottom of the oxidation tank filler is directly blown and aerated, and the biofilm is directly strongly disturbed by the updraft, which renews quickly and maintains a high activity. At the same time, the influent load is stable. Under certain circumstances, the biofilm can maintain a certain thickness and is not prone to cl...

Embodiment 2

[0060] In this example, using figure 1 Processing device shown.

[0061] The farmhouse catering wastewater collected through the pipe network flows into the oil separation sedimentation tank 1 by itself, and the suspended solids and oil in the sewage are initially separated by natural flotation, so as to prevent it from clogging the subsequent treatment unit and reduce the load of subsequent treatment, and then pass through The pretreated sewage enters the aerobic tank 2, and a combined film-hanging filler is set in the aerobic tank, and microorganisms are inoculated. The growth provides strong conditions and increases its contact area with the sewage. The bottom of the oxidation tank filler is directly blown and aerated, and the biofilm is directly strongly disturbed by the updraft, which renews quickly and maintains a high activity. At the same time, the influent load is stable. Under certain circumstances, the biofilm can maintain a certain thickness and is not prone to cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com