Method for efficiently preparing graphene-like carbon nitride

A technology of ene carbon nitride and graphite, which is applied in the field of synthesis of graphene-like carbon nitride, can solve the disadvantages of rapid acquisition and further promotion and application of graphene-like carbon nitride, and the small specific surface area of graphene-like carbon nitride , The preparation efficiency and effect are not ideal, etc., to achieve the effect of rapid and uniform heat treatment, controllable structure and properties, and rapid and efficient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] After mixing 10g of melamine and 0.2g of polypropylene-based carbon fiber, put it into a ceramic crucible. Then place the ceramic crucible in the resonant cavity of an industrial high-energy microwave oven and evacuate to 5kPa, set the microwave power to 5kW, and start to keep warm after the temperature reaches 570°C, turn off the microwave oven after 5min, let the reaction system cool down to room temperature with the furnace, and then take out the sample . It can be seen that there is a large amount of light yellow powder in the crucible, that is, graphene-like carbon nitride, the yield is about 54wt%, and the specific surface area is 307m 2 / g.

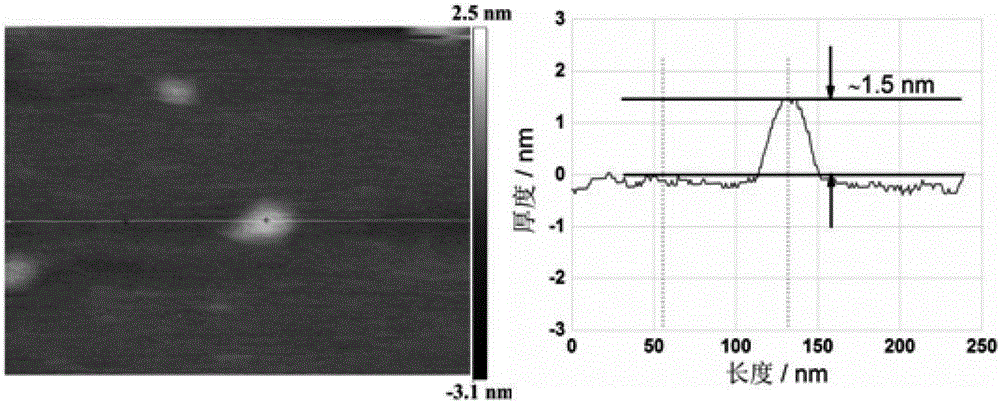

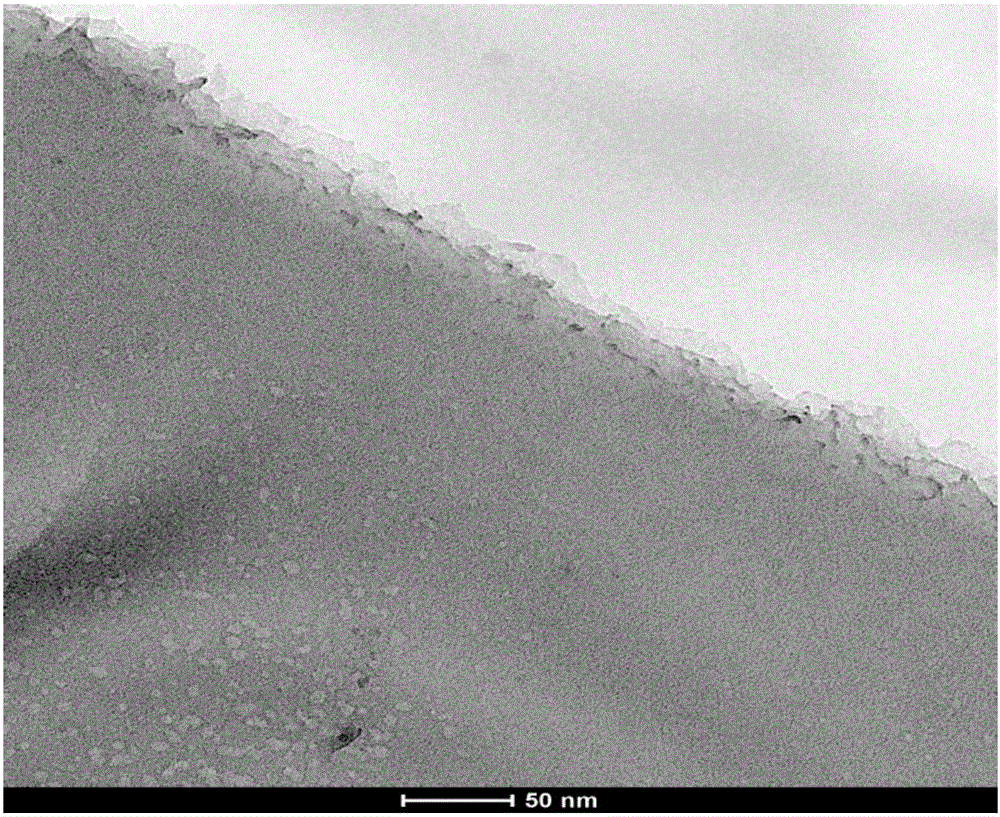

[0046] figure 1 The transmission electron micrograph of the obtained product shows that the product has an obvious layered structure with a thickness of about 4 layers. figure 2 It is an atomic force microscope picture of the obtained product. It can be seen from the figure that the thickness of the obtained graphene-lik...

Embodiment 2

[0048] After mixing 10g of melamine and 0.4g of polypropylene-based carbon fiber, put it into a ceramic crucible. Then place the ceramic crucible in the resonant cavity of an industrial high-energy microwave oven and evacuate it to 10kPa, set the microwave power to 4kW, and keep warm after the temperature reaches 500°C, turn off the microwave oven after 15 minutes, let the reaction system cool down to room temperature with the furnace, and then take out the sample . It can be seen that there is a large amount of light yellow powder in the crucible, that is, graphene-like carbon nitride, the yield is about 44wt%, and the specific surface area is 183m 2 / g, the sheet thickness is about 8 layers.

Embodiment 3

[0050] After mixing 10g of dicyandiamide and 0.5g of polypropylene-based carbon fiber, put it into a ceramic crucible. Then place the ceramic crucible in the resonant cavity of an industrial high-energy microwave oven and evacuate it to 15kPa; set the microwave power to 6kW, keep warm after the temperature reaches 600°C, turn off the microwave oven after 10min, let the reaction system cool down to room temperature with the furnace, and then take out the sample . It can be seen that there is a large amount of light yellow powder in the crucible, that is, graphene-like carbon nitride, the yield is about 49wt%, and the specific surface area is 209m 2 / g, the sheet thickness is about 6 layers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com