Vanadium trioxide nanoparticles and preparation method thereof

A vanadium trioxide nanometer and nanoparticle technology, applied in the field of materials, can solve the problems of unfavorable large-scale production, high cost of raw materials, complicated methods, etc., and achieve the effect of convenient self-assembly into devices, high specific surface area, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

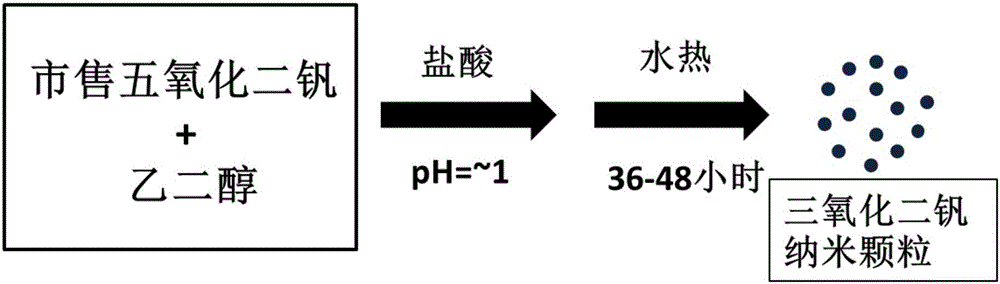

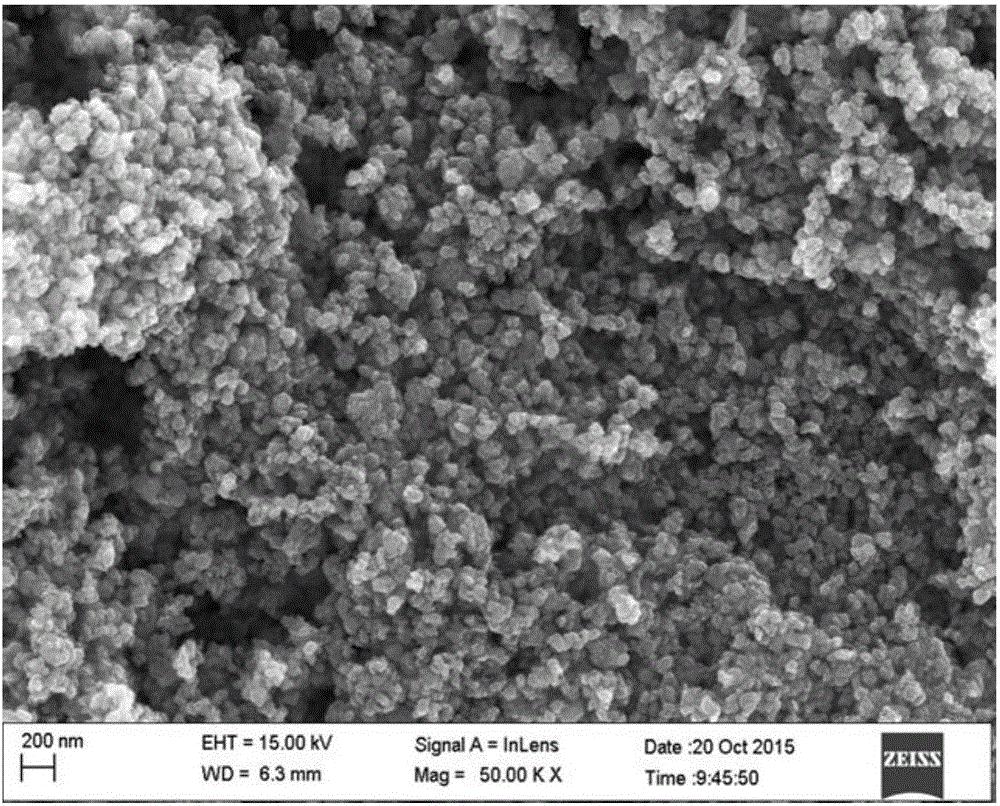

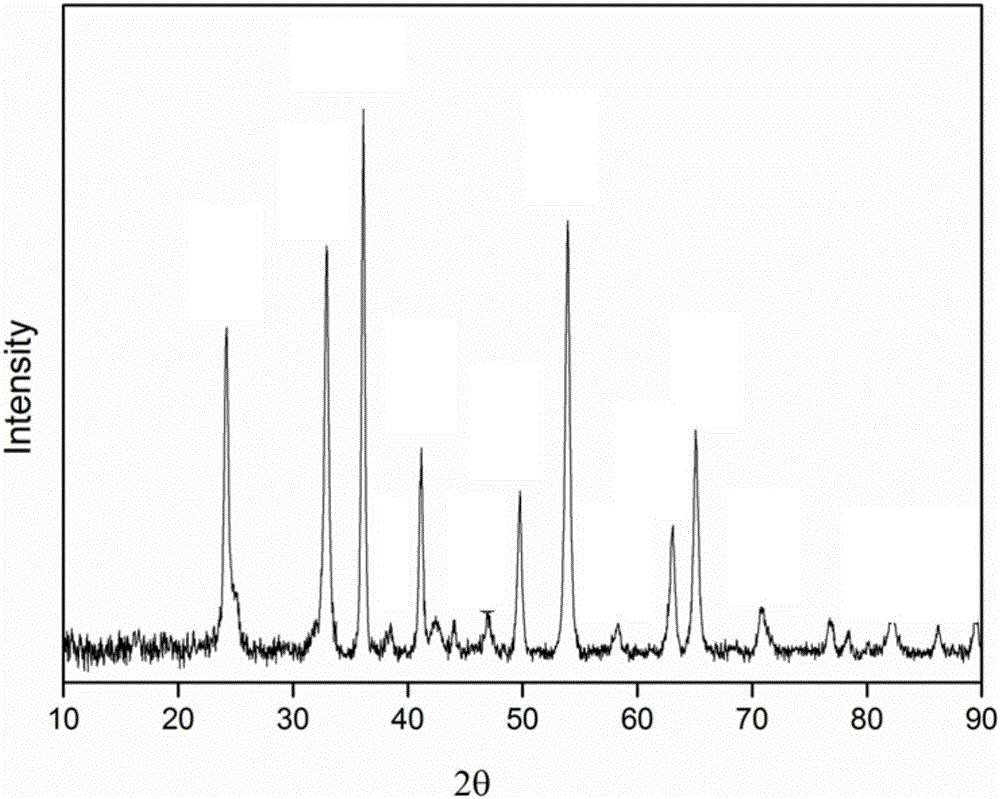

[0034] Follow the steps below to prepare vanadium trioxide nanoparticles:

[0035] 1) Add commercially available vanadium pentoxide into the ethylene glycol solution, and vigorously stir in a water bath at 50°C for 2 hours to make it evenly mixed to form suspension A; the molar concentration of vanadium pentoxide in suspension A is 0.1 M;

[0036] 2) Add 1 mL of hydrochloric acid to the suspension A, so that the color of the suspension A changes from brownish yellow to dark red to form a suspension B, wherein the mass concentration of hydrochloric acid is 23%;

[0037] 3) Put the suspension B into an autoclave and heat it. The heating temperature is 200°C and the heating time is 36 hours. After standing at room temperature and cooling, the mixed solution containing dark blue precipitate can be obtained;

[0038]4) Centrifuge the mixed solution containing dark blue precipitate formed in step 3) at a centrifugal speed of 2000-3000rpm, wash with ethanol and deionized water respe...

Embodiment 2

[0040] Nanoparticles were prepared as follows:

[0041] 1) Add commercial vanadium pentoxide to ethylene glycol solution, stir vigorously in a water bath at 70°C for 2 hours to make it evenly mixed to form suspension A; the molar concentration of vanadium pentoxide in suspension A is 0.2mM ;

[0042] 2) Add 3 mL of hydrochloric acid to the suspension A, so that the color of the suspension A changes from brownish yellow to dark red to form a suspension B, wherein the mass concentration of hydrochloric acid is 23%;

[0043] 3) Put the suspension B into an autoclave and heat it, the heating temperature is 240°C, the heating time is 40 hours, and after cooling at room temperature, a mixed solution containing a dark blue precipitate can be obtained;

[0044] 4) Centrifuge the mixed solution containing dark blue precipitate formed in step 3) at a centrifugal speed of 2000-3000rpm, wash with ethanol and deionized water respectively until the supernatant is colorless and transparent,...

Embodiment 3

[0046] Nanoparticles were prepared as follows:

[0047] 1) Add commercial vanadium pentoxide into the ethylene glycol solution, and stir vigorously in a water bath at 60°C for 2 hours to make it evenly mixed to form suspension A; the molar concentration of vanadium pentoxide in suspension A is 0.25mM ;

[0048] 2) Add 4 mL of hydrochloric acid to the suspension A, so that the color of the suspension A changes from brownish yellow to dark red to form a suspension B, wherein the mass concentration of hydrochloric acid is 36%;

[0049] 3) Put the suspension B into an autoclave and heat it. The heating temperature is 260°C and the heating time is 44 hours. After standing at room temperature and cooling, a mixed solution containing a dark blue precipitate can be obtained;

[0050] 4) Centrifuge the mixed solution containing dark blue precipitate formed in step 3) at a centrifugal speed of 2000-3000rpm, wash with ethanol and deionized water respectively until the supernatant is col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com