A kind of preparation method with nanohole IR nanowire and its obtained material and application

A technology of nanoholes and nanowires, applied in the field of Ir nanowire materials, can solve the problems of complicated and time-consuming steps, and achieve the effect of simple and fast operation, convenient operation and uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

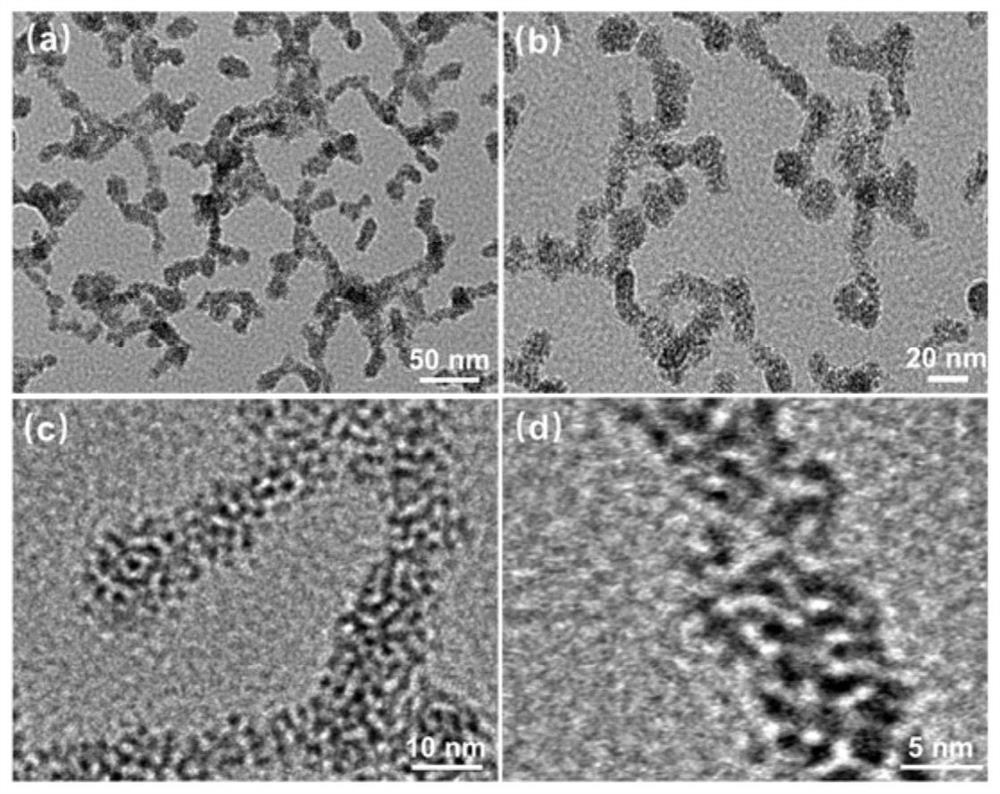

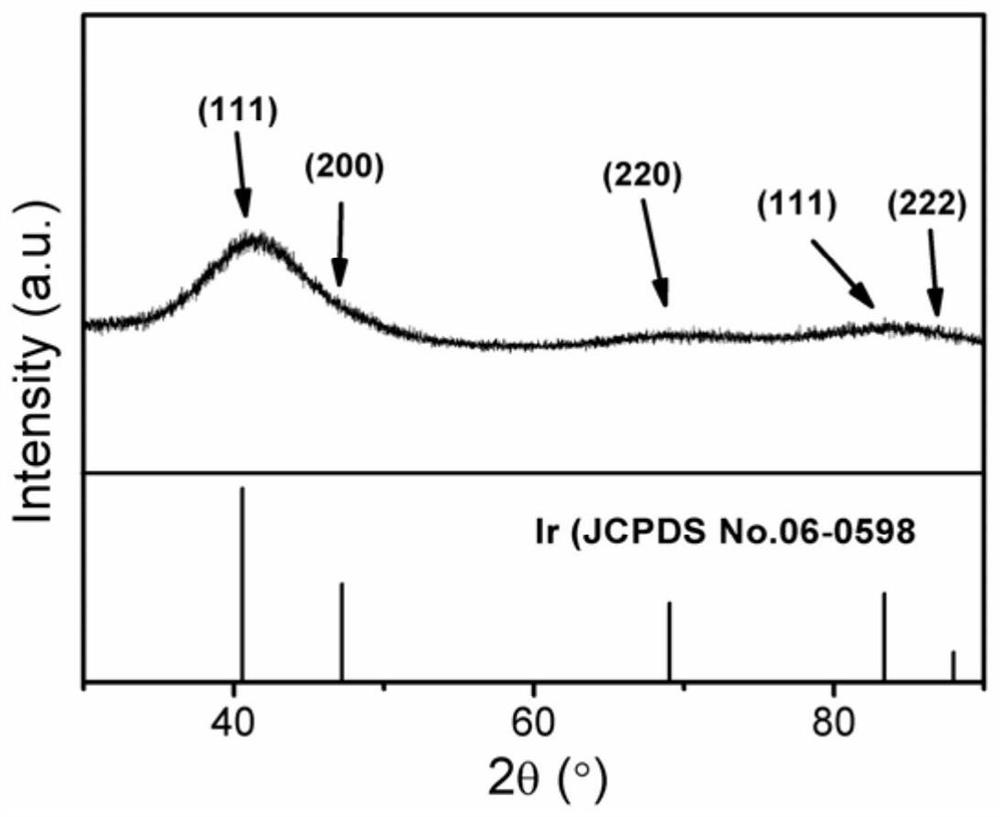

Image

Examples

Embodiment 1

[0024] A method for ultrafast and macro-scale preparation of Ir nanowires with nanoholes, comprising the following steps:

[0025] 1) Preparation of reaction solution: Measure 10mL of aqueous solution as a solvent in a 25ml reactor liner, add 1mL of 0.5mol L -1 PAH solution was used as a shape-directing agent, adding 1mL 0.05mol L -1 IrCl 3 The solution was used as a precursor, and after stirring for 30 minutes, NaOH solution was added to adjust the pH of the solution to 10. After ultrasonication for 30 minutes, 1 mL of 40% formaldehyde solution was added.

[0026] 2) Preparation of Ir nanowires with nanoholes: place the prepared reaction solution in an oven at 200°C for 8 hours, and centrifuge and wash the brown-black product three times with a solution of deionized water:ethanol=3:1 after the reaction , Ir nanowires with nanoholes can be obtained by vacuum drying at room temperature for 6 h.

Embodiment 2

[0028] A method for ultrafast and macro-scale preparation of Ir nanowires with nanoholes, comprising the following steps:

[0029] 1) Preparation of reaction solution: Measure 10mL of aqueous solution as a solvent in a 25ml reactor liner, add 1.5mL of 0.5mol L -1 PAH solution of 0.05mol L -1 IrCl 3 The solution was used as a precursor, and after stirring for 30 minutes, NaOH solution was added to adjust the pH of the solution to 10. After ultrasonication for 30 minutes, 1 mL of 40% formaldehyde solution was added.

[0030] 2) Preparation of Ir nanowires with nanoholes: place the prepared reaction solution in an oven at 200°C for 8 hours, and centrifuge and wash the brown-black product three times with a solution of deionized water:ethanol=3:1 after the reaction , Ir nanowires with nanoholes can be obtained by vacuum drying at room temperature for 6 h.

Embodiment 3

[0032] A method for ultrafast and macro-scale preparation of Ir nanowires with nanoholes, comprising the following steps:

[0033] 1) Preparation of reaction solution: Measure 10mL of aqueous solution as a solvent in a 25ml reactor liner, add 0.1mL of 0.5mol L -1 PAH solution was used as a shape-directing agent, adding 1.5mL 0.05mol L -1 IrCl 3 The solution was used as a precursor, after stirring for 30 minutes, NaOH solution was added to adjust the pH of the solution to 9, and after 30 minutes of ultrasonication, 1 mL of 40% formaldehyde solution was added.

[0034] 2) Preparation of Ir nanowires with nanoholes: place the prepared reaction solution in an oven at 200°C for 8 hours, and centrifuge and wash the brown-black product three times with a solution of deionized water:ethanol=3:1 after the reaction , Ir nanowires with nanoholes can be obtained by vacuum drying at room temperature for 6 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com