Magnetic conversion engine

A technology of engines and rotors, applied in the direction of generators/motors, electrical components, etc., can solve the problem that the fundamental defects of DC motors and AC motors have not been truly eliminated, and achieve good dynamic response, high ratio, and flexible and convenient control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

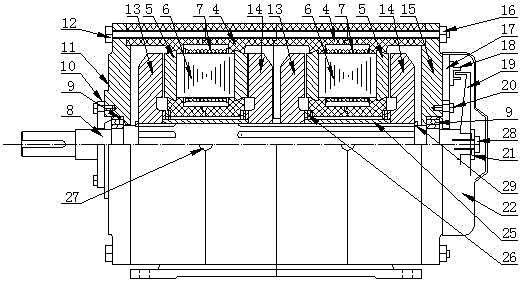

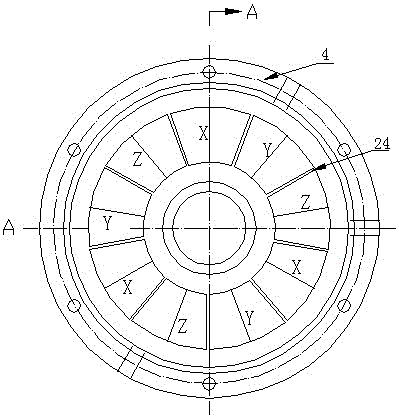

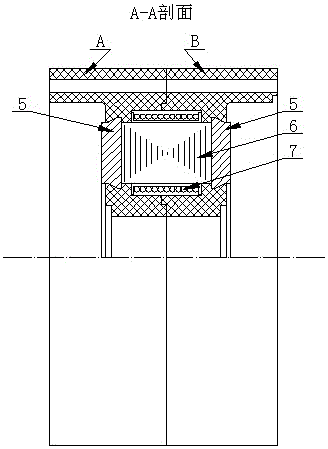

[0030] The overall structure of the magnetic conversion motor of the present invention is as follows: figure 1 1 is the permanent magnet, 2 is the soft magnetic pole, 3 is the notch of the rotor pole, 4 is the stator, 5 is the additional magnetic pole of the stator core, 6 is the iron core, 7 is the winding coil, 8 is the spline shaft, 9 is Bearing, 10 is the bearing end cover, 11 is the left end cover, 12 is the bolt, 13 is the left rotor, 14 is the right rotor, 15 is the right end cover, 16 is the nut, 17 is the photoelectric device fixing plate, 18 is the photoelectric device, 19 is a light interceptor, 20 is a fastening bolt of a photoelectric device fixing plate, 21 is a washer, 22 is a protective cover, 23 is a gap between a soft magnetic pole and a permanent magnetic pole, 24 is a gap between an additional magnetic pole of an iron core, and 25 is a Positioning sleeve, 26 is the thrust bearing, 27 is the lead wire hole, 28 is the fastening bolt of the light cutter, 29 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com