Method for screening reasonable welding process parameters based on impact toughness

A technology of welding process and impact toughness, which is applied in the field of mechanical performance evaluation and characterization of materials, can solve the problems of single impact toughness evaluation method and complicated operation, and achieve the effect of simple pre-treatment, convenient operation and less welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

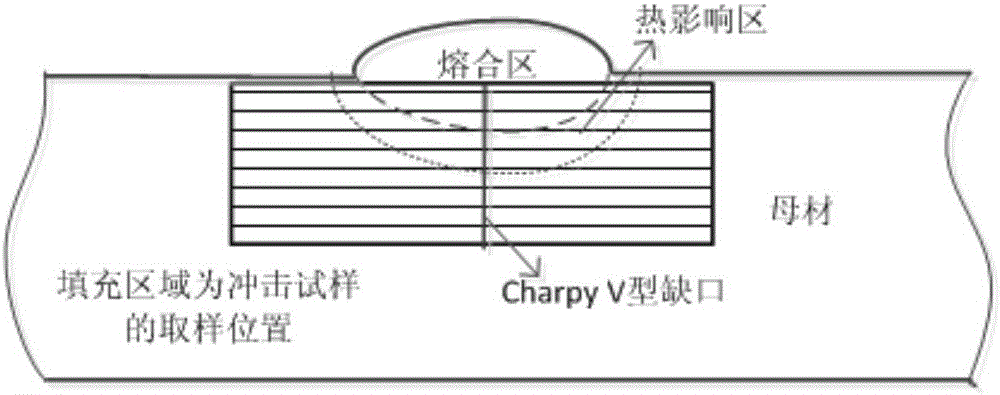

[0049] A method for quickly screening reasonable welding process parameters based on impact toughness, specifically comprising the following steps:

[0050] Step 1, Q690MPa high-strength steel plate pretreatment:

[0051] Three pieces of Q690MPa high-strength steel plates with a size of 20mm×400mm×100mm were prepared respectively, and the Q690MPa high-strength steel plates were pretreated respectively, and one surface of the steel plates was polished with a grinding wheel, and the surface oxide scale and oil stains were removed to make the surface of the steel plates smooth;

[0052] Step 2, single pass welding:

[0053] In the middle position of the Q690MPa high-strength steel plate, submerged arc welding is used for single-pass welding to obtain a welded plate including a complete welding heat-affected zone. Among them, the process parameters of three sets of single-pass welding are: welding current, welding voltage and Welding speed, heat input = welding voltage × welding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com