Lamiophlomis rotata(Benth.) Kudo solid dispersion preparation and preparation method thereof

A solid dispersion, unique technology, applied in the field of medicine, can solve the problems of large dosage, difficult storage of granules, low dissolution rate of preparations, etc. The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

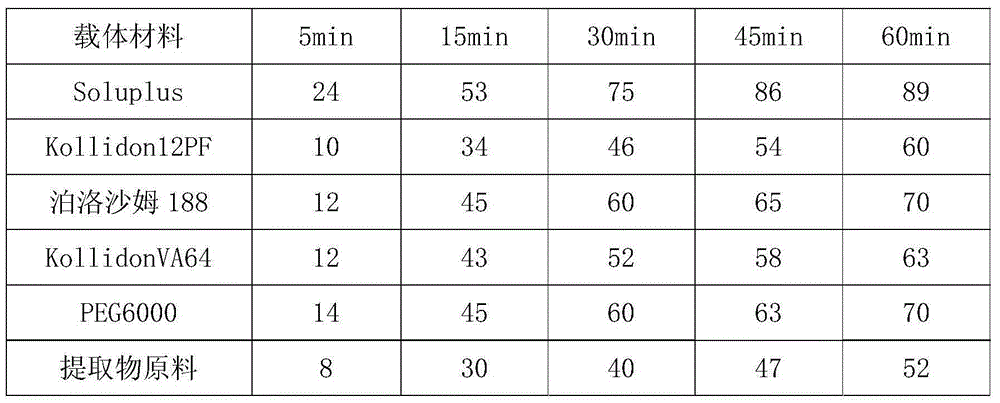

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1: the preparation of unique tablet

[0058] (1) Take 800g of Duyiwei, add 3 times the amount of 80% ethanol to soak overnight, reflux extraction for 2 hours, filter to obtain the extract, the filtrate recovers ethanol and concentrates to an extract with a relative density of about 1.20, and vacuum-dries to make a dry extract Yantuo extract extract powder, add 5 times water to the dregs, boil again for 2 hours, filter, concentrate the filtrate, dry and pulverize, combine twice to extract the powder, and set aside;

[0059] (2) Set the control temperature of the Haake micro-mixing rheometer to 110°C, the screw speed to 30r / min, and the torque to 20N.cm; place 200g of the drug carrier material Soluplus with the unique extract powder prepared in step 1) In the hopper, the material is extruded in the shape of strips from the die hole of the machine head after being extruded, cooled at room temperature, crushed, and passed through an 80-mesh sieve to obtain a soli...

Embodiment 2

[0061] Embodiment 2: the preparation of unique soft capsule

[0062] (1) Take 1000g of Duyiwei, add 3 times the amount of 80% ethanol to soak overnight, reflux extraction for 2 hours, filter to obtain the extract, recycle the ethanol from the filtrate and concentrate it to an extract with a relative density of about 1.20, and vacuum dry it to make a dry extract Yantuo extract extract powder, add 5 times water to the dregs, boil again for 2 hours, filter, concentrate the filtrate, dry and pulverize, combine twice to extract the powder, and set aside;

[0063] (2) Set the control temperature of the Haake micro-mixing rheometer to 110°C, the screw speed to 30r / min, and the torque to 20N.cm; put 300g of the drug carrier material Soluplus with the unique extract powder prepared in step 1) In the hopper, the material is extruded in the shape of strips from the die hole of the machine head after being extruded, cooled at room temperature, crushed, and passed through an 80-mesh sieve ...

Embodiment 3

[0065] Embodiment 3: the preparation of unique soft capsule

[0066] (1) Take 1200g of Duyiwei, add 3 times the amount of 80% ethanol to soak overnight, reflux extraction for 2 hours, filter to obtain the extract, the filtrate recovers ethanol and concentrates to an extract with a relative density of about 1.20, and vacuum-dries to make a dry extract Yantuo extract extract powder, add 5 times water to the dregs, boil again for 2 hours, filter, concentrate the filtrate, dry and pulverize, combine twice to extract the powder, and set aside;

[0067] (2) Set the control temperature of the Haake micro-mixing rheometer to 110°C, the screw speed to 30r / min, and the torque to 20N.cm; place 400g of the drug carrier material Soluplus with the unique extract powder prepared in step 1) In the hopper, the material is extruded in the shape of strips from the die hole of the machine head after being extruded, cooled at room temperature, crushed, and passed through an 80-mesh sieve to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com