Containment vessel long-term pressure relief filtration system

A filtration system and containment technology, applied in nuclear power generation, climate sustainability, emergency protection devices, etc., can solve the problems of insufficient contact time, harsh operating conditions, slow chemical reaction rate, etc., to improve the removal efficiency and ensure Stable, good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

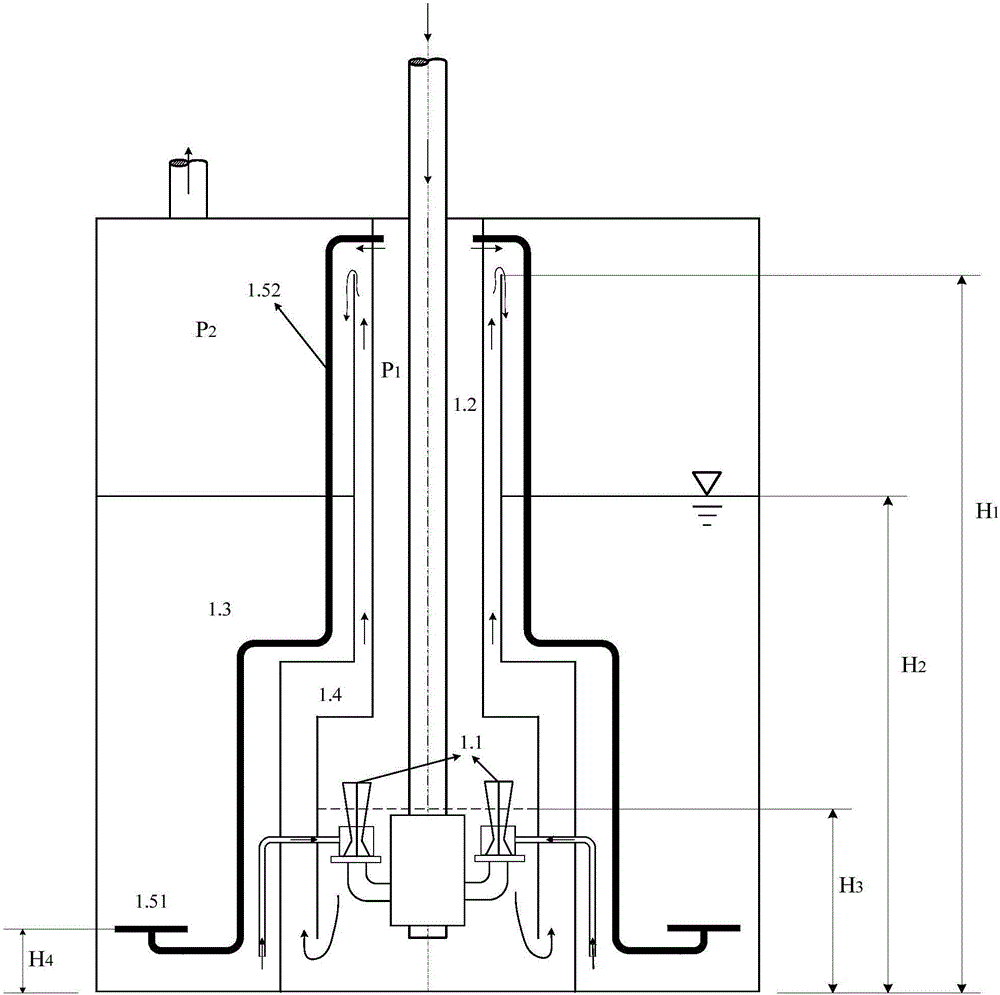

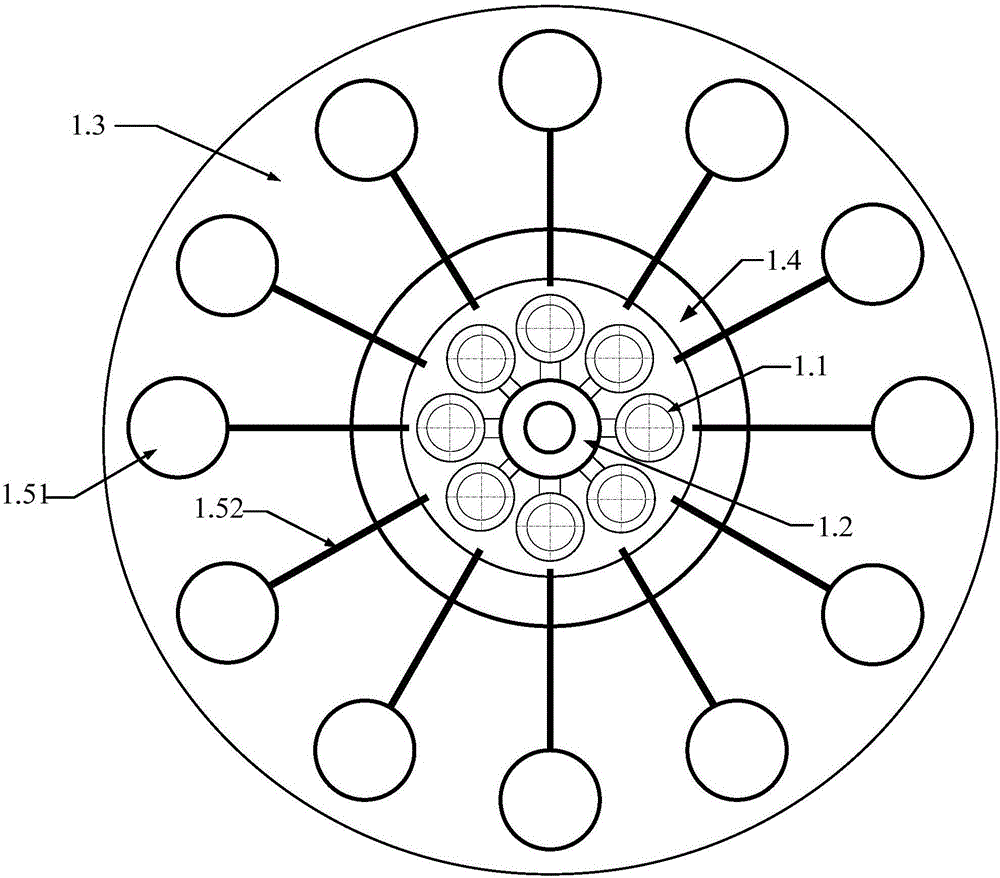

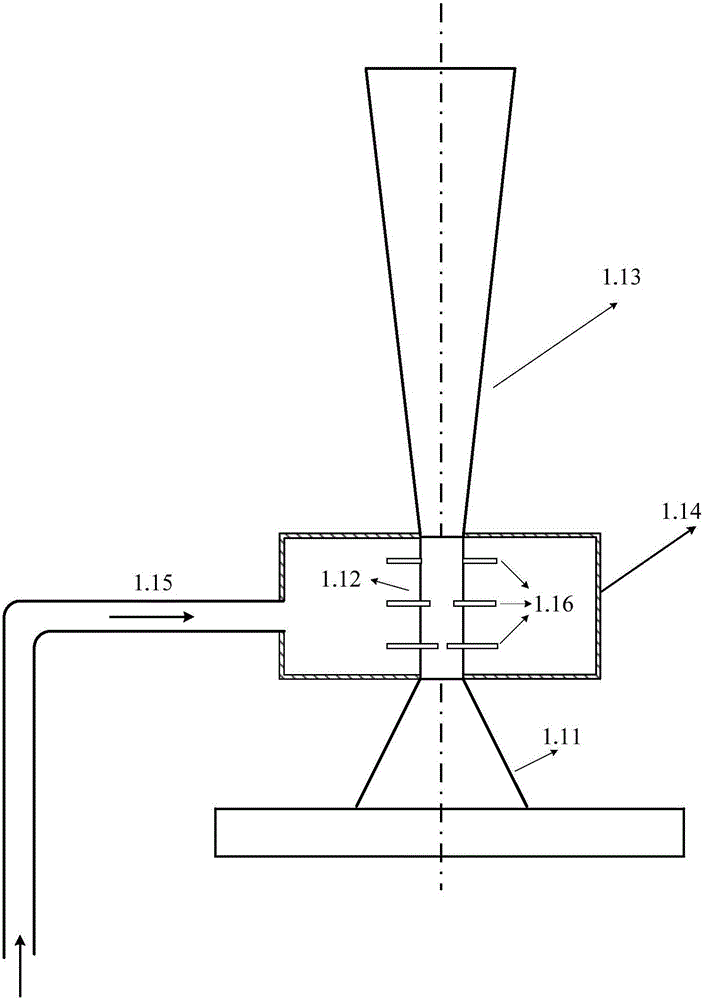

[0018] combined with Figure 1-4 , the present invention includes: (1) a self-priming Venturi scrubber 1.1 with high dust and gas removal efficiency; (2) a Venturi scrubber chamber 1.2 located in the central area of the system for enveloping the Venturi scrubber, At the same time, the static pressure in the upper space of the chamber provides the driving force for the gas to enter the bubbling chamber 1.3; (3) a bubble generation system for dividing the continuous gas phase into discrete bubbles; (4) the bubbling absorption system located at the periphery of the system Chamber 1.3, the gas forms a uniform bubbly flow in the chamber, which is used to improve the absorption efficiency of methyl iodide gas and the removal efficiency of small particle size aerosols; (5) the boundary of Venturi scrubber chamber 1.2 and the bubbling chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com