Ecological antibacterial high-sensitivity polyester fiber and method for producing same

A polyester fiber and production method technology, applied in the field of ecological antibacterial high-sensitivity polyester fiber and its production, can solve the problems of low comfort and wearability, antibacterial effect, poor dimensional stability of breathable and moisture permeability, etc. Ease of operation and the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] An ecological antibacterial high-sensitivity polyester fiber, its breaking strength is 2.0-3.5cN / dtex, and its fracture growth rate is 10-25%. More than 90%, the antibacterial rate of Escherichia coli is greater than 92%; the far-infrared emission rate of ecological antibacterial high-sensitivity polyester fiber is greater than 85%.

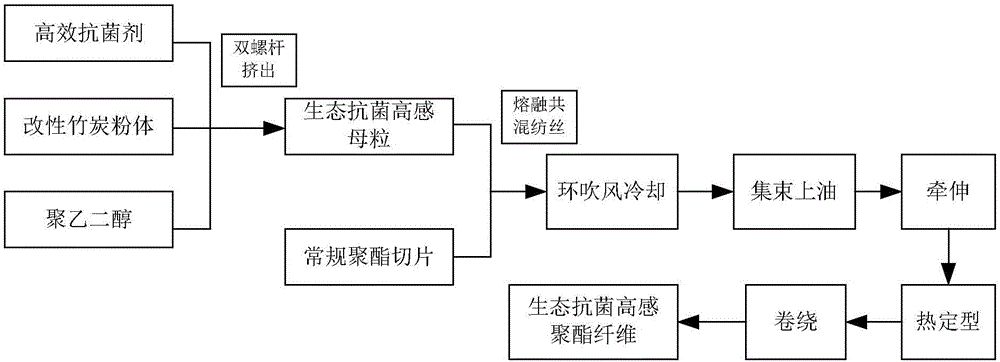

[0058] Please see attached figure 1 , a kind of production method of ecological antibacterial high-sensitivity polyester fiber, its specific steps are:

[0059] (1) Preparation of ecological antibacterial high-sensitivity masterbatch, with high-efficiency antibacterial agent, modified bamboo charcoal powder, polyethylene glycol as raw materials, through the method of twin-screw melt blending extrusion, to prepare ecological antibacterial high-sensitivity masterbatch;

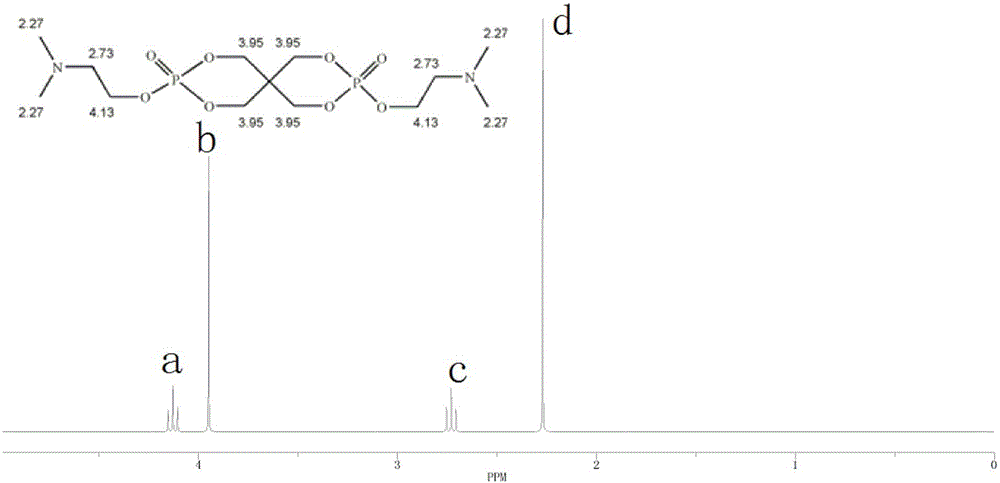

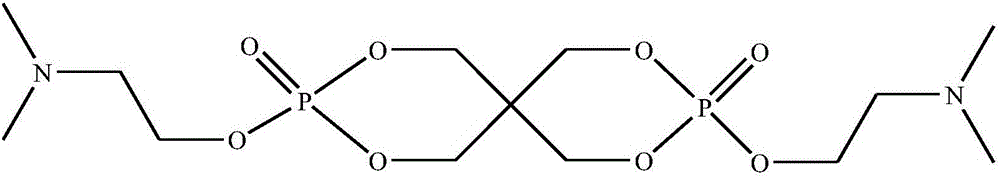

[0060] The high-efficiency antibacterial agent is a novel antibacterial agent containing amino antibacterial groups, specifically bisdimethylaminoethanol pentaerythritol di...

Embodiment 2

[0078] An ecological antibacterial high-sensitivity polyester fiber, its breaking strength is 2.0-3.5cN / dtex, and its fracture growth rate is 10-25%. More than 90%, the antibacterial rate of Escherichia coli is greater than 92%; the far-infrared emission rate of ecological antibacterial high-sensitivity polyester fiber is greater than 85%.

[0079] A kind of production method of ecological antibacterial high-sensitivity polyester fiber, its specific steps are:

[0080] (1) Preparation of ecological antibacterial high-sensitivity masterbatch, with high-efficiency antibacterial agent, modified bamboo charcoal powder, polyethylene glycol as raw materials, through the method of twin-screw melt blending extrusion, to prepare ecological antibacterial high-sensitivity masterbatch;

[0081] The high-efficiency antibacterial agent is a novel antibacterial agent containing amino antibacterial groups, specifically bisdimethylaminoethanol pentaerythritol diphosphate.

[0082] The prepara...

Embodiment 3

[0096] An ecological antibacterial high-sensitivity polyester fiber, its breaking strength is 2.0-3.5cN / dtex, and its fracture growth rate is 10-25%. More than 90%, the antibacterial rate of Escherichia coli is greater than 92%; the far-infrared emission rate of ecological antibacterial high-sensitivity polyester fiber is greater than 85%.

[0097] A kind of production method of ecological antibacterial high-sensitivity polyester fiber, its specific steps are:

[0098] (1) Preparation of ecological antibacterial high-sensitivity masterbatch, with high-efficiency antibacterial agent, modified bamboo charcoal powder, polyethylene glycol as raw materials, through the method of twin-screw melt blending extrusion, to prepare ecological antibacterial high-sensitivity masterbatch;

[0099] The high-efficiency antibacterial agent is a novel antibacterial agent containing amino antibacterial groups.

[0100] The preparation method of bis-dimethylaminoethanol pentaerythritol diphosphat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com