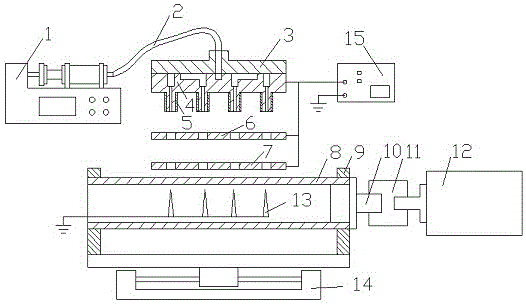

Electrostatic spinning device for batch preparation of orderly nanofibers

A technology for electrospinning, nanofibers, used in fiber processing, textile and papermaking, filament/thread forming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

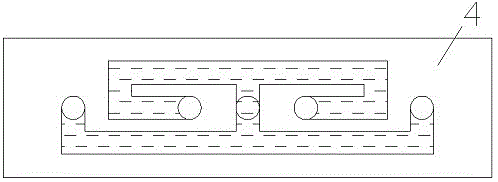

[0013] exist figure 1 Among them, the catheter (2), the liquid inlet plate (4), the insulating sleeve (5), the roller (8), the support seat (9), and the rotating shaft (10) are all made of insulators, and the nozzle plate (4) and The upper orifice plate (6) and the lower orifice plate (7) are made of conductive material. The liquid inlet plate (3) is fixedly connected with the nozzle plate (4) as a spinning nozzle, the quantitative liquid supply pump (1) is connected with the through hole on the liquid inlet plate (3) through the liquid guide tube (2), and the quantitative liquid supply pump (1) Realize the solution supply to the spinning nozzle. The insulating sleeves (5) are respectively connected to and cover the nozzle arrays on the nozzle plate (4) to realize electrical isolation between the nozzles, reduce mutual electrostatic inhibition and balance the electric field strength at the nozzles. The through-hole arrays on the upper orifice plate (6) and the lower orifice ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com