Nitrogen and phosphorus containing leather fire retardant and preparation method thereof

A technology of flame retardant and leather, applied in the field of high-efficiency synergistic flame retardant containing nitrogen and phosphorus and its preparation, can solve the problems of unfavorable popularization and application, high production cost, and reduced mechanical strength, and achieve simple and easy preparation process, Improve flame retardant efficiency and good filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

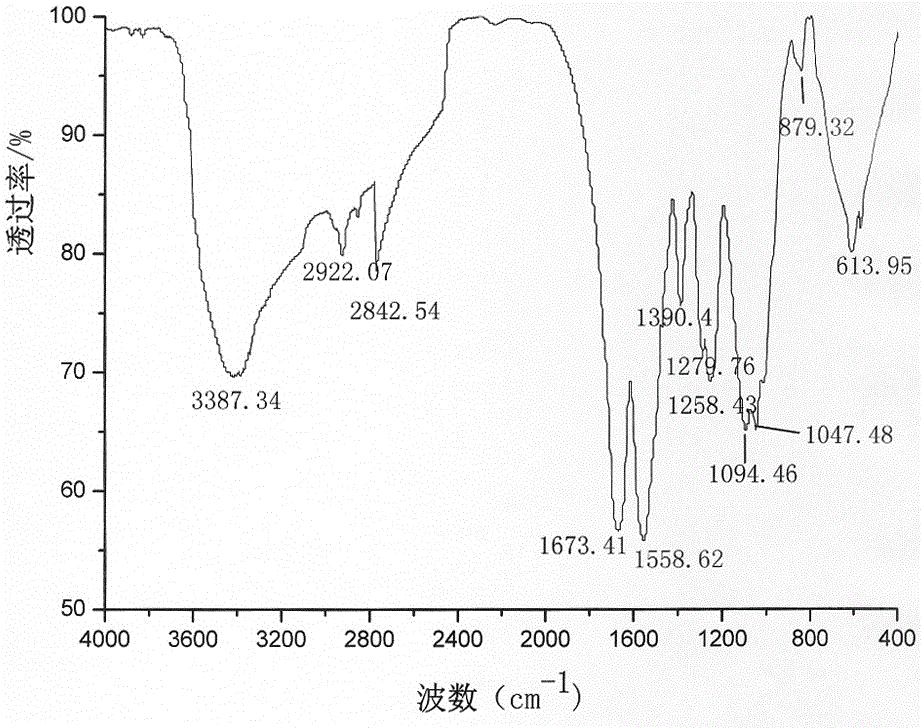

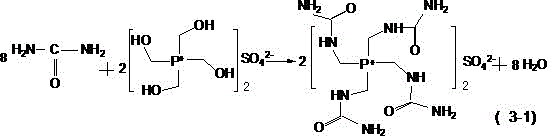

[0022] Embodiment 1: a kind of nitrogen-containing phosphorus-containing leather flame retardant, described flame retardant is hydroxymethylated four hydroxymethyl phosphorus urea, and its structural formula is: (HOCH 2 HNCONHCH 2 ) n P + (CH 2 NHCONH 2 ) 4-n (1≤n≤4).

Embodiment 2

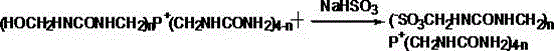

[0023] Example 2: The first preparation method for preparing the above-mentioned nitrogen-containing and phosphorus-containing leather flame retardant, adding 4 parts of urea into a double-necked bottle connected with a condenser tube, and adding a small amount of deionized water, and placing it at a constant temperature Stir in a water-bath magnetic stirrer, add 1 part of quaternary phosphonium salt during slow heating, continue to heat up to 90 ° C, after 1 hour of reaction, add a small amount of deionized water, continue reaction for 1 hour until the reaction is complete. After the solution is naturally cooled, adjust the pH to 9.0 with 0.5mol / L NaOH, weigh 3 parts of formaldehyde, slowly add the formaldehyde into the double-necked bottle, add a small amount of distilled water, place it in a constant temperature water bath magnetic stirrer, and heat to 65 ℃, stirred for 1 hour, then added 0.9 part of sulfonating agent to carry out sulfonation reaction, and continued to stir ...

Embodiment 3

[0024] Embodiment 3: the second preparation method of the nitrogen-containing and phosphorus-containing leather flame retardant as described above is similar to Example 1, adding 4 parts of urea to a double-necked bottle connected with a condenser tube, and adding a small amount of deionized Water, placed in a constant temperature water bath magnetic stirrer, add 1 part of quaternary phosphonium salt during slow heating, continue to heat up to 100 ° C, after 1 hour of reaction, add a small amount of deionized water, continue reaction for 1 hour until the reaction is complete. After the solution is naturally cooled, adjust the pH to 8.5 with 0.5mol / L NaOH, weigh 2.5 parts of formaldehyde, slowly add the formaldehyde into the double-necked bottle, add a small amount of distilled water, place it in a constant temperature water bath magnetic stirrer, and heat to 70 ℃, after stirring for 1 h, add 1 part of sulfonating agent to carry out sulfonation reaction, and continue stirring fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com