Borate-based rare earth ion doping visible-ultraviolet up-conversion luminescent material and preparation method and application thereof

A technology of rare earth ions and luminescent materials, applied in luminescent materials, botanical equipment and methods, applications, etc., can solve the problems of inability to kill large-area bacteria, small laser excitation area, hidden dangers of operation and use, and achieve sterilization Or the effect of inhibiting bacterial growth, low price, and reducing sterilization costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

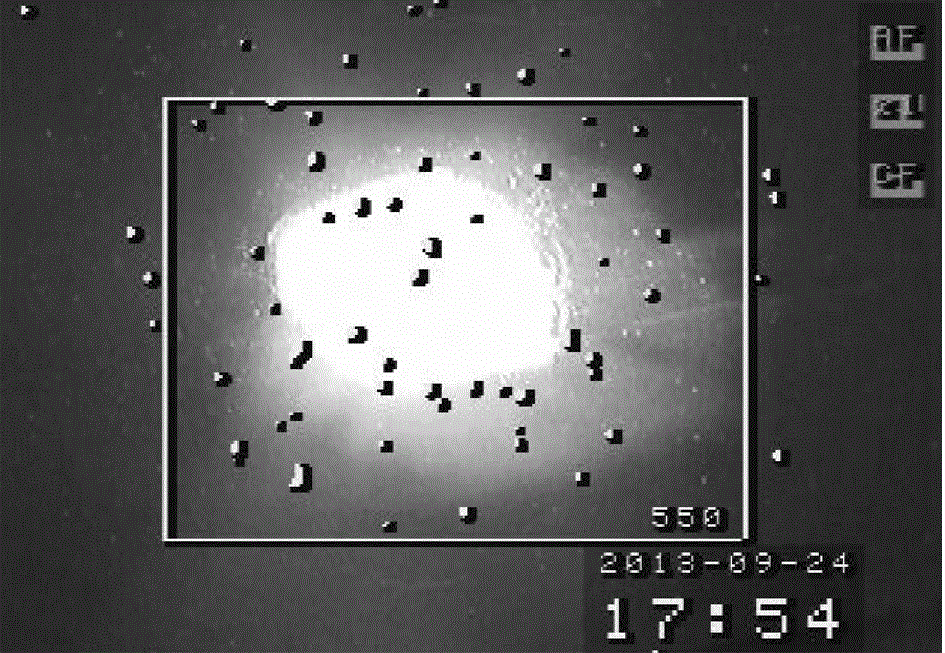

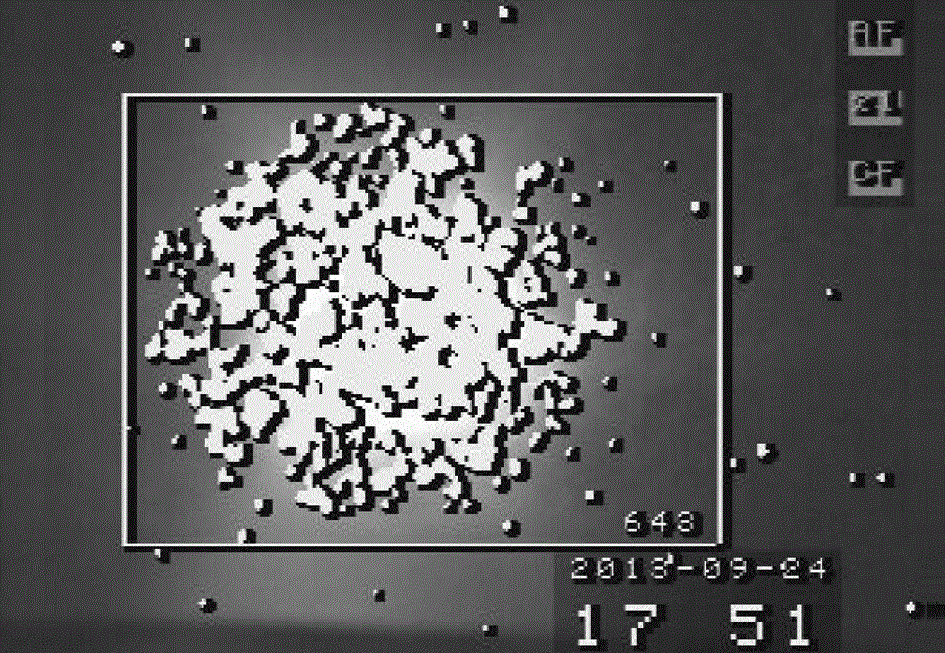

Image

Examples

Embodiment 1

[0034] Weigh magnesium oxide, praseodymium oxide and boric acid according to the molar ratio of each element magnesium: praseodymium: boron = 0.99:0.01:2.05, mix and grind to powder, burn at 1000°C for 2 hours after crushing, cool down to room temperature, take out, grind, The powdered magnesium borate-based rare earth visible-ultraviolet up-conversion luminescent material is obtained.

Embodiment 2

[0036]According to the molar ratio of each element magnesium: praseodymium: lithium: boron = 0.9:0.01:0.09:2.05 Weigh magnesium oxide, praseodymium oxide, lithium carbonate and boric acid, mix and grind to powder, after crushing, burn at 1000°C for 2h, drop to room temperature, taken out, and ground to obtain a powdery magnesium borate-based rare earth visible-ultraviolet up-conversion luminescent material.

Embodiment 3

[0038] Weigh magnesium oxide, yttrium oxide, praseodymium oxide and boric acid according to the molar ratio of each element magnesium: yttrium: praseodymium: boron = 1:0.99:0.01:2.05, mix and grind to powder, then burn at 1200°C for 1 hour after crushing to room temperature, taken out, and ground to obtain a powdery yttrium-magnesium borate-based rare earth visible-ultraviolet up-conversion luminescent material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com