Titanium dioxide airflow crushing method and apparatus

A technology of jet pulverization and jet pulverizer, which is applied in chemical instruments and methods, treatment of dyed organosilicon compounds, treatment of inorganic pigments, etc., can solve the problems of difficult measurement, affecting the amount of organic treatment agents, and affecting the pigment performance of titanium dioxide products. , to achieve the effect of full contact with the material and improve the dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

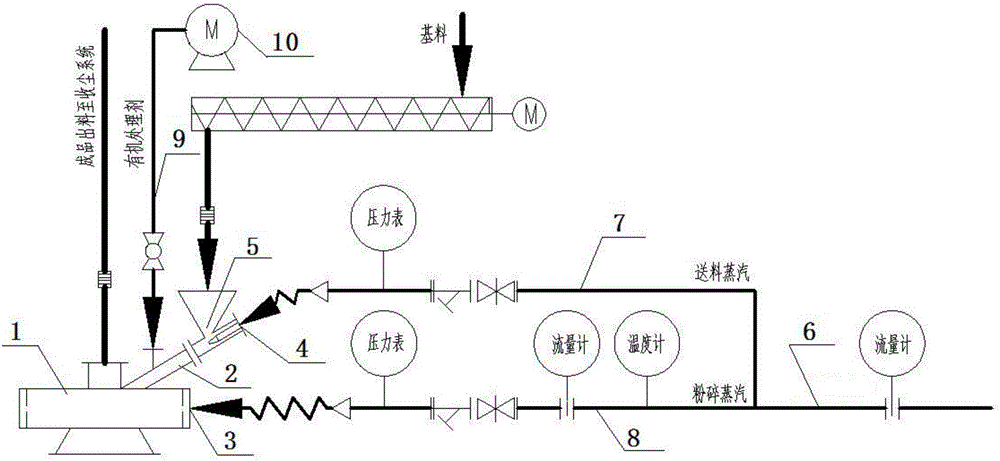

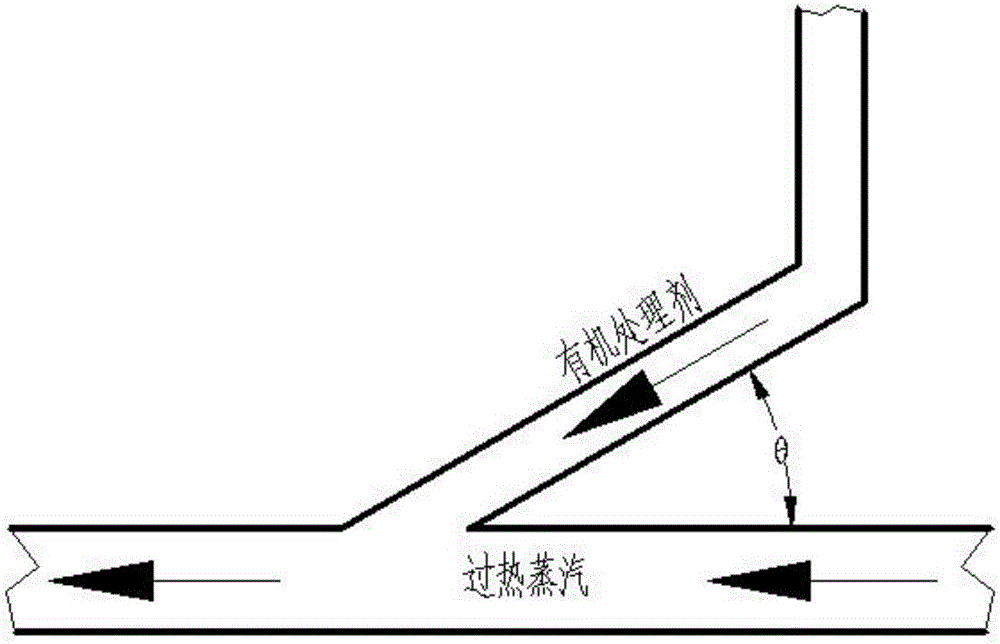

[0041] Such as figure 2 and image 3 As shown, adopt the method base material of the present invention to carry out jet pulverization: jet pulverizer and dust collection system are preheated with superheated steam until the system is stable, simultaneously open the base material inlet on the long feed pipe and the steam main pipe. Organic treatment agent feed tube. The base material is fed into the long feeding pipe through the feeding screw, and the organic treatment agent is injected into the steam main pipe through the metering pump and the Venturi principle. Steam enters the crushing chamber. Maintain the crushing steam pressure at 1.5MPa, feed steam at 1.0MPa, bag filter temperature at 200°C, gas-solid ratio at 2.0, organic treatment agent / TiO2=0.005 (mass ratio), jet mill feed rate at 2.0t / h, and the system runs stably until Produce 2000t products, according to a batch number of 20 tons, test the performance and dispersibility of the product pigments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com