Preparation method of polyurethane elastomer containing stereoregular complex crystal

A technology of polyurethane elastomer and stereocomplex crystallization, which is applied in the field of polyurethane elastomer, can solve problems such as difficulty in realization, and achieve the effects of low pollution, high mechanical strength and modulus, and high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

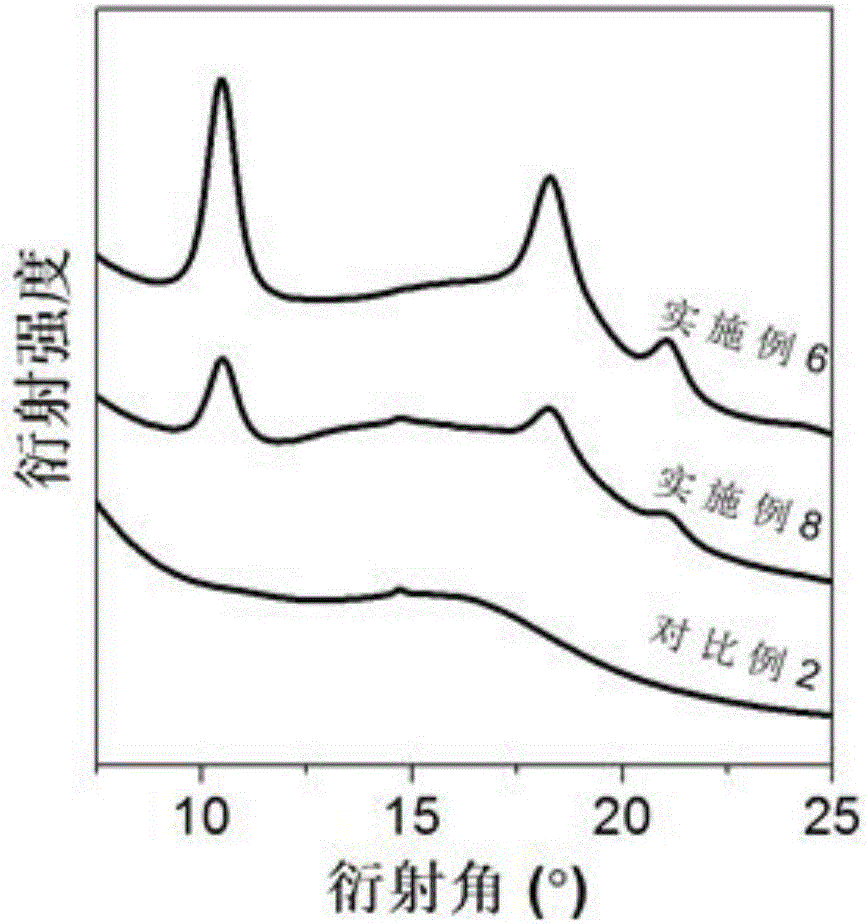

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] In the following examples and comparative examples, the double-terminated hydroxyl-terminated PEB used was purchased from Sartomer, USA. The L-lactide used was purchased from Purac, and the D-lactide was provided by Zhejiang Mingzhong Institute of Biomedical Materials and Devices. L-lactide and D-lactide were recrystallized in ethyl acetate to remove impurities, and dried in vacuum at 60°C to constant weight. HDI and IPDI were purchased from Wanhua Chemical Company, and PHDI, stannous octoate, and dibutyltin dilaurate were purchased from Sigma Company.

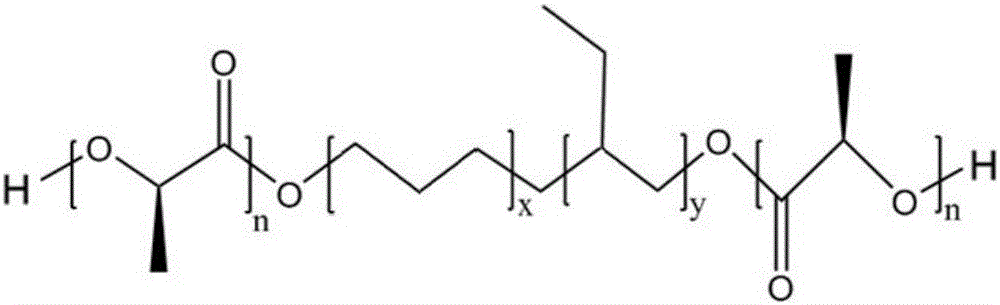

[0033] PLLA-PEB-PLLA and PDLA-PEB-PDLA triblock copolymers terminated with double-terminal hydroxyl groups were synthesized according to the method described in Chinese patent (patent number: ZL201510058848.4). The specific method is as follows: add PEB and lactide with prede...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com