Nanopolymer Capsules Embedded with Oxygen Sensitive Fluorescent Indicator and Its Preparation and Application

A fluorescent indicator and nano-polymer technology, which is applied in the direction of fluorescence/phosphorescence, luminescent materials, and material analysis through optical means, and can solve the problems of indicator leakage, difficulty in accurately controlling the pore structure of the membrane matrix, and easy leakage of the indicator. , to achieve the effect of solving the leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

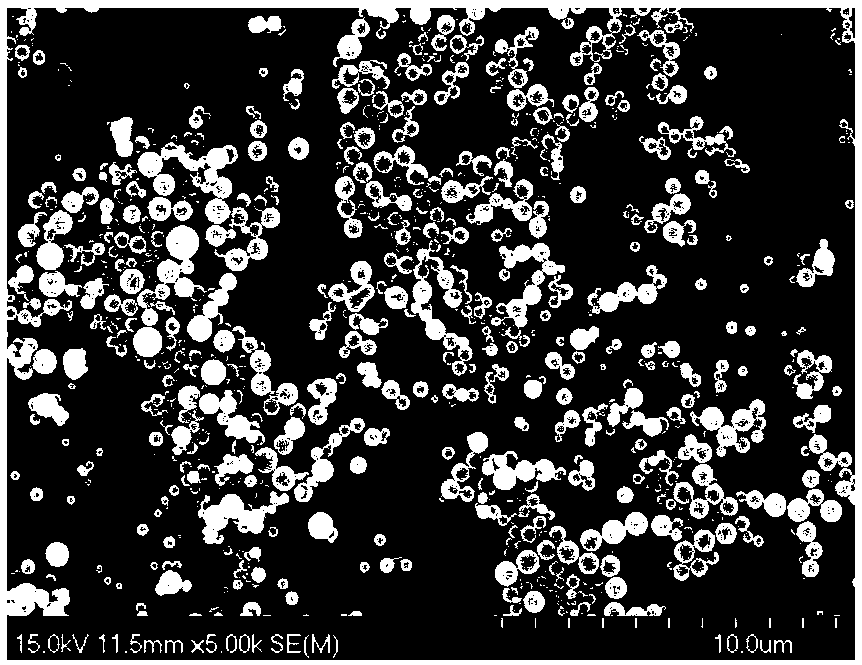

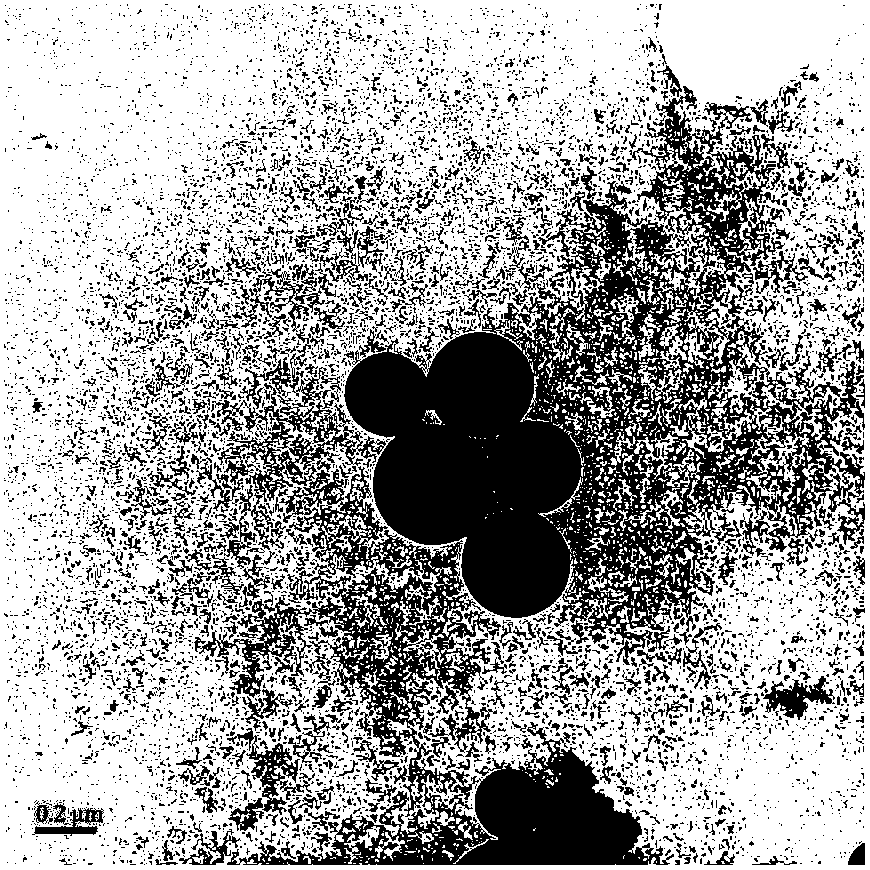

[0052] (1) Prepare fluorine-free nanopolymer capsules embedded with an oxygen-sensitive fluorescent indicator with a core-shell ratio of 1:1, with an average particle size of 218.6nm. The specific steps are as follows:

[0053] 0.30 gram of amphiphilic macromolecular RAFT reagent and 49.70 gram of deionized water are prepared into an aqueous solution as the water phase, and 3.55 gram of methyl methacrylate, 1.42 gram of p-divinylbenzene, 0.07 gram of azobisisobutyl Nitrile, 4.94 g of paraffin and 0.02 g of tris(4,7-biphenyl-1,10-phenanthroline) ruthenium dichloride oil phase were mixed uniformly and ultrasonically pulverized for 20 minutes to obtain a fine emulsion. The miniemulsion is subjected to RAFT active radical miniemulsion polymerization under the condition of 160° C., cooled after reacting for 5 hours, and fluorine-free nanometer polymer capsules embedded with oxygen-sensitive fluorescent indicators are prepared.

[0054] (2) preparing an oxygen-sensitive fluorescent ...

Embodiment 2

[0058] Preparation of fluorine-free nanopolymer capsules embedded with oxygen-sensitive fluorescent indicators with a core-shell ratio of 1:2, with an average particle size of 228.7nm, and preparation of fluorine-free nanopolymer capsules embedded with oxygen-sensitive fluorescent indicators The oxygen-sensitive fluorescent film with a capsule concentration of 20%, the specific steps are as follows:

[0059] (1) 0.3 gram of amphiphilic macromolecular RAFT reagent and 49.7 gram of deionized water are mixed into an aqueous solution as the water phase, and 4.72 gram of methyl methacrylate, 1.89 gram of p-divinylbenzene, 0.09 gram of azo Diisobutyronitrile, 3.29 grams of paraffin and 0.01 grams of tris (4,7-biphenyl-1,10-phenanthroline) ruthenium dichloride oil phase and mixed evenly, after ultrasonic pulverization for 20 minutes to obtain a fine emulsion . The miniemulsion was subjected to RAFT active radical miniemulsion polymerization reaction at 160°C, and cooled after 5 hour...

Embodiment 3

[0062] The method of this embodiment is the same as that of Example 2, except that the dosage of the amphiphilic macromolecular RAFT agent is 0.32, 0.34, 0.36, and 0.38 grams respectively, and the particle size of the polymer capsule is regulated, and the model is ZEN1600 through the Marr Wen laser particle size analyzer tested the particle size of nano-polymer particles prepared by different amounts of RAFT reagents, and the average particle sizes were 215nm, 163.7nm, 152.9nm, and 146.0nm;

[0063] According to the method of Example 1, the oxygen-sensitive fluorescent films containing the nano-polymer capsules prepared in this example at a concentration of 20% were respectively prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com