Device and method for preparing trichlorosilane from silicon tetrachloride

A technology of silicon tetrachloride and trichlorosilane, applied in chemical instruments and methods, silicon halide compounds, inorganic chemistry, etc., can solve the problems of loss of electrodes, increase of experimental errors, high electron work function, etc., and reduce breakdown Voltage, increased electron density, and wide operating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

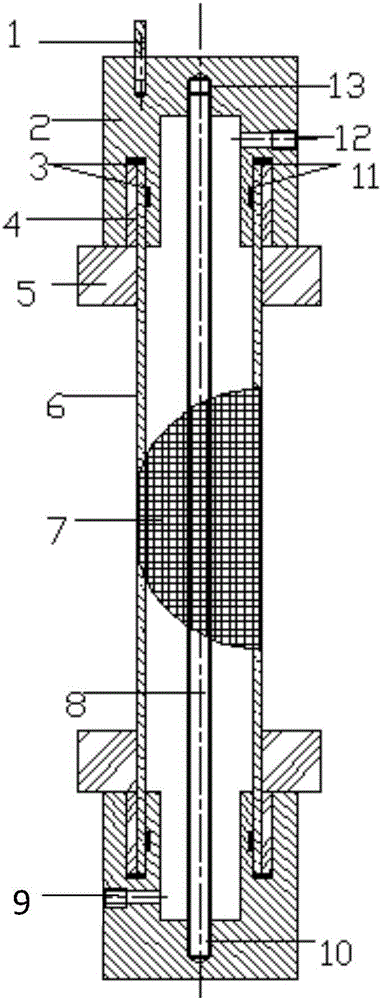

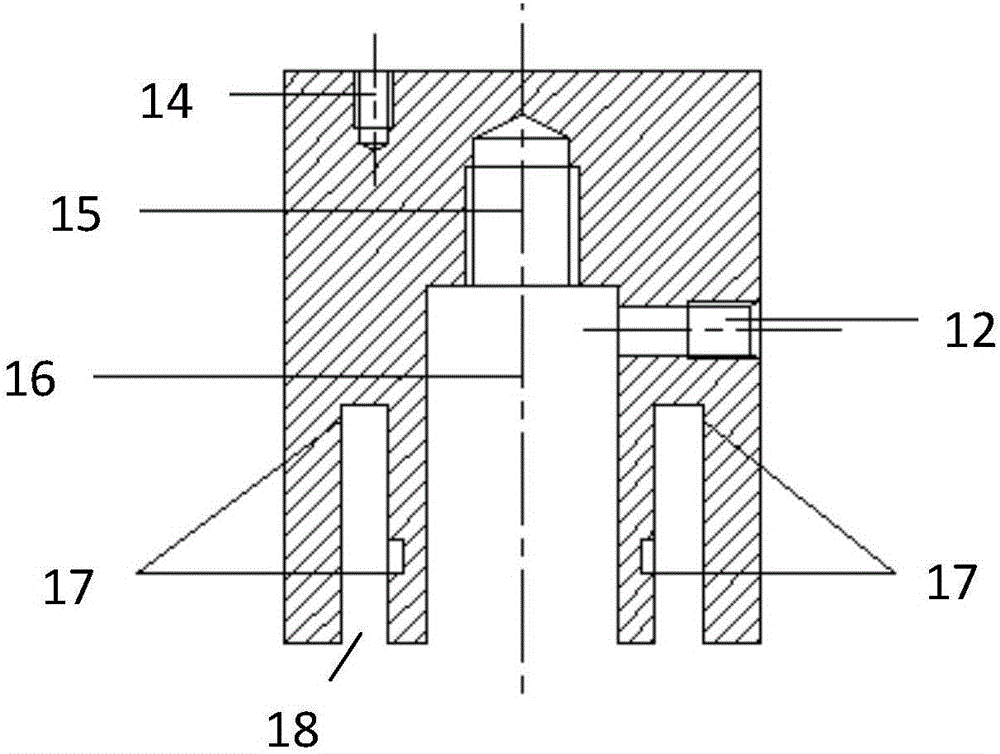

[0036] Embodiment 1, with reference to figure 1 and figure 2 , the device for preparing trichlorosilane with silicon tetrachloride, which is a medium-barrier low-temperature plasma hydrogenation reactor for silicon tetrachloride, which includes a sealing flange 2, a variable backing ring 4, a high-pressure barrier ring 5, The dielectric 6, the external electrode 7 and the internal electrode 8, the above-mentioned components are coaxially arranged, the internal electrode 8 is located at the axis position of the reactor, and the upper end 13 of the inner electrode and the lower end 10 of the inner electrode are respectively connected to the sealing flanges 2 at both ends; The two ends of the dielectric 6 are respectively connected to the sealing flanges 2 at both ends and the inner electrode 8 is set inside, the high-voltage barrier ring 5 is set on the dielectric 6, and is closely attached to the sealing flange 2, and the outer electrode 7 is tightly wrapped in the dielectric ...

Embodiment 2

[0050] Example 2, using the same reactor as in Example 1, the difference is that the feed molar ratio of hydrogen to silicon tetrachloride is 1:6, and in step 1), the hydrogen temperature is 20°C and the pressure is 0.1 MPa, the temperature of silicon tetrachloride is 20°C, the two are mixed and introduced into the reactor, the temperature of the mixed gas is 20°C, the pressure is 0.1MPa, and the flow rate of hydrogen is 2L / min.

[0051] In step 2), the power frequency is 3MHz, the voltage is 30kV, and the power is 1000kW.

Embodiment 3

[0052] Example 3, using the same reactor as in Example 1, the difference is that the feed molar ratio of hydrogen to silicon tetrachloride is 1:20, and in step 1), the hydrogen temperature is 30°C and the pressure is 0.1 MPa, the temperature of silicon tetrachloride is 30°C, the two are mixed and introduced into the reactor, the temperature of the mixed gas is 30°C, the pressure is 0.1MPa, and the flow rate of hydrogen is 1L / min.

[0053] In step 2), the power frequency is 5kHz, the voltage is 5kV, and the power is 20kW.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com