A kind of two-component waterborne polyurethane adhesive and the construction method of paving stadium

A technology of water-based polyurethane and construction method, which is applied in the direction of polyurea/polyurethane adhesive, polymer adhesive additive, non-polymer adhesive additive, etc., which can solve the problem of high hardness, poor initial adhesion and poor flexibility of products And other problems, to achieve the effect of good initial viscosity, improved viscosity and good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

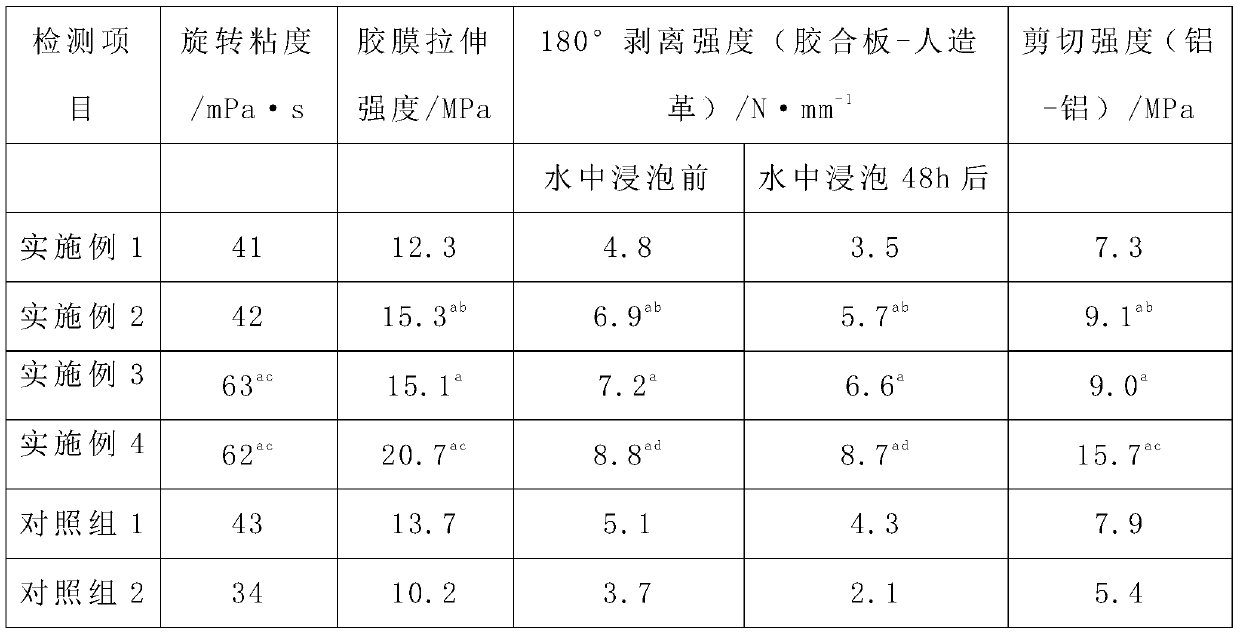

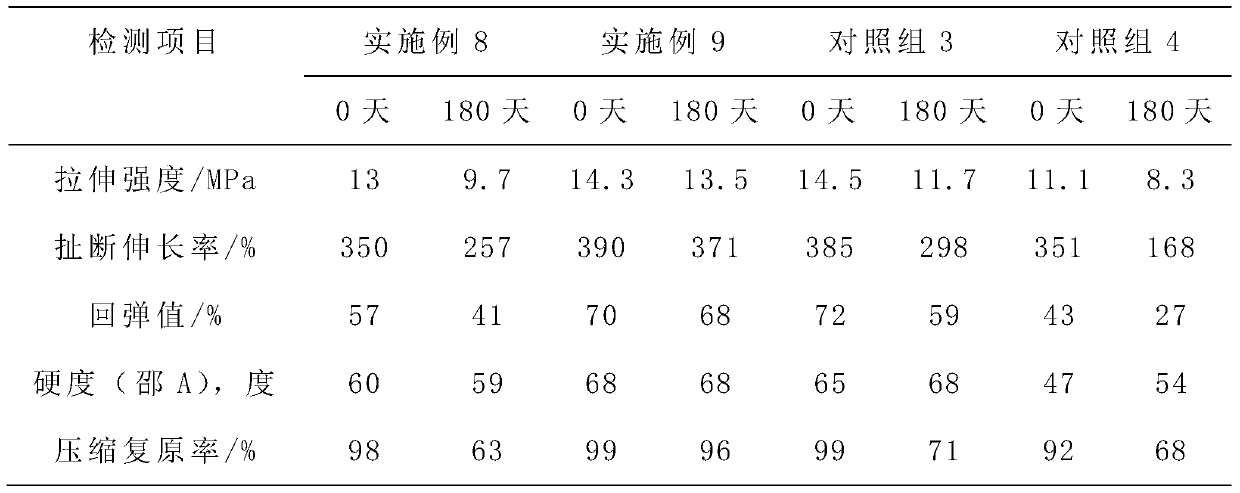

Examples

Embodiment 1

[0025] A two-component water-based polyurethane adhesive, the adhesive is made up of component A, component B and deionized water, and the parts by weight of raw materials are as follows:

[0026] Component A: Water-dispersible isocyanate 6

[0027] Component B: Aqueous hydroxyacrylic dispersion 40

[0028] Carboxylated styrene-butadiene latex 2

[0029] Nitrile Latex 3

[0030] Coconut fatty acid acyldiethanolamine phosphate 0.2

[0031] Glycerol trihydroxypolyether 0.02

[0032] Iron Oxide Red 1

[0033] Ethyl gallate 1

[0034] Deionized water 70.

Embodiment 2

[0036] A two-component water-based polyurethane adhesive, the adhesive is made up of component A, component B and deionized water, and the parts by weight of raw materials are as follows:

[0037] Component A: Water-dispersible isocyanate 6

[0038] Component B: Aqueous hydroxyacrylic dispersion 40

[0039] 5-Demethoxypineol 2.5

[0040] Carboxylated styrene-butadiene latex 1.25

[0041] Nitrile Latex 1.25

[0042] Coconut fatty acid acyldiethanolamine phosphate 0.2

[0043] Glycerol trihydroxypolyether 0.02

[0044] Iron Oxide Red 1

[0045] Ethyl gallate 1

[0046] Deionized water 70.

Embodiment 3

[0048] A two-component water-based polyurethane adhesive, the adhesive is made up of component A, component B and deionized water, and the parts by weight of raw materials are as follows:

[0049] Component A: Water-dispersible isocyanate 20

[0050]Component B: Waterborne hydroxyacrylic dispersion 60

[0051] 5-Demethoxypineol 4

[0052] Carboxylated styrene-butadiene latex 2

[0053] Nitrile Latex 2

[0054] Polyoxyethylene (400) laurate 0.5

[0055] Dimethicone 0.06

[0056] Iron Oxide Red 3

[0057] Propyl gallate 2

[0058] Tourmaline powder 5.625

[0059] Medical stone powder 9.375

[0060] Deionized water 140.

[0061] Among them, the water-based hydroxyacrylic acid dispersion is a copolymer emulsion of methacrylate, acrylic acid and hydroxyl methacrylate with a core-shell structure modified by N-methylolacrylamide; methacrylate, acrylic acid, methacrylic acid The mass-number ratio of hydroxyester and N-methylolacrylamide is 2:2:1:5;

[0062] The specific pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com