Flame retardant PS composite and method of processing flame retardant PS composite

A technology of composite materials and mixtures, which is applied in the field of flame-retardant PS composite materials and its preparation, can solve the problems of high burning speed and other problems that have not been reported before, and achieve the effect of improving physical properties and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of any one of the above flame-retardant PS composite materials, comprising the following steps:

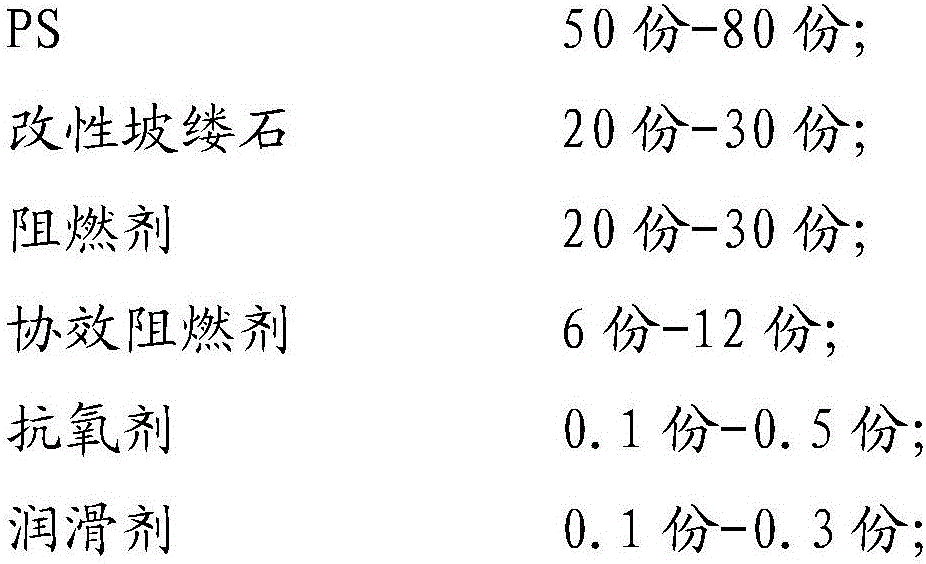

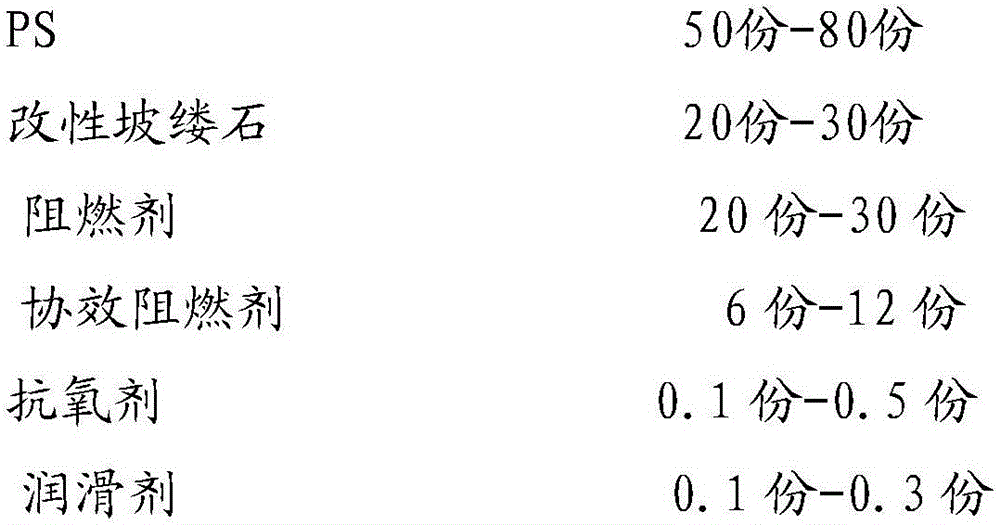

[0039] (1) Weigh 50-80 parts of PS, 20-30 parts of modified palygorskite, 20-30 parts of APP, 6-12 parts of melamine, 0.1-0.5 parts of antioxidant, 0.1-0.3 parts of lubricants are mixed and stirred evenly to obtain a mixture;

[0040] (2) Extruding and granulating the mixture obtained in step (1) to obtain a PS composite material.

[0041] Preferably, the step (2) specifically includes: putting the mixture obtained in the step (1) into the hopper of a twin-screw extruder to extrude and granulate to obtain a PS composite material, wherein the twin-screw extruder The output machine includes six temperature zones arranged in sequence, the temperature of the first zone is 160-180°C, the temperature of the second zone is 180-220°C, the temperature of the third zone is 180-220°C, the temperature of the fourth zone is 180-220°C, and the temperature of the f...

preparation example 1

[0048] Modified palygorskite, its preparation method is as follows:

[0049] (1) Weigh a certain amount of hydrochloric acid and palygorskite into a three-necked flask, heat and react in an oil bath at 80-100°C for 6-10h, filter the resulting precipitate with suction, and dry the obtained product A; hydrochloric acid and palygorskite The ratio of the amount of stone to substance is 6:3.

[0050] (2) Weigh a certain amount of A and octadecyltrimethylammonium bromide into the mouth of a three-neck flask, heat and react in an oil bath at 60-80°C for 8-14h, centrifugally filter the resulting product, and dry Acquired modified palygorskite; wherein the ratio of A to octadecyltrimethylammonium bromide is 20:8.

preparation example 2

[0052] Modified palygorskite, its preparation method is as follows:

[0053] (1) Weigh a certain amount of hydrochloric acid and palygorskite into a three-necked flask, heat and react in an oil bath at 80-100°C for 6-10h, filter the resulting precipitate with suction, and dry the obtained product A; hydrochloric acid and palygorskite The ratio of the amount of stone to substance is 6:7.

[0054] (2) Weigh a certain amount of A and octadecyltrimethylammonium bromide into the mouth of a three-neck flask, heat and react in an oil bath at 60-80°C for 8-14h, centrifugally filter the resulting product, and dry Acquired modified palygorskite; wherein the ratio of A to octadecyltrimethylammonium bromide is 20:15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com