Method for constructing Sema 4D/Heparin microenvironment on surface of cardiovascular implanted material

An implant material, cardiovascular technology, applied in pharmaceutical formulations, coatings, pharmaceutical sciences, etc., can solve problems such as no discovery, and achieve the effect of delaying half-life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

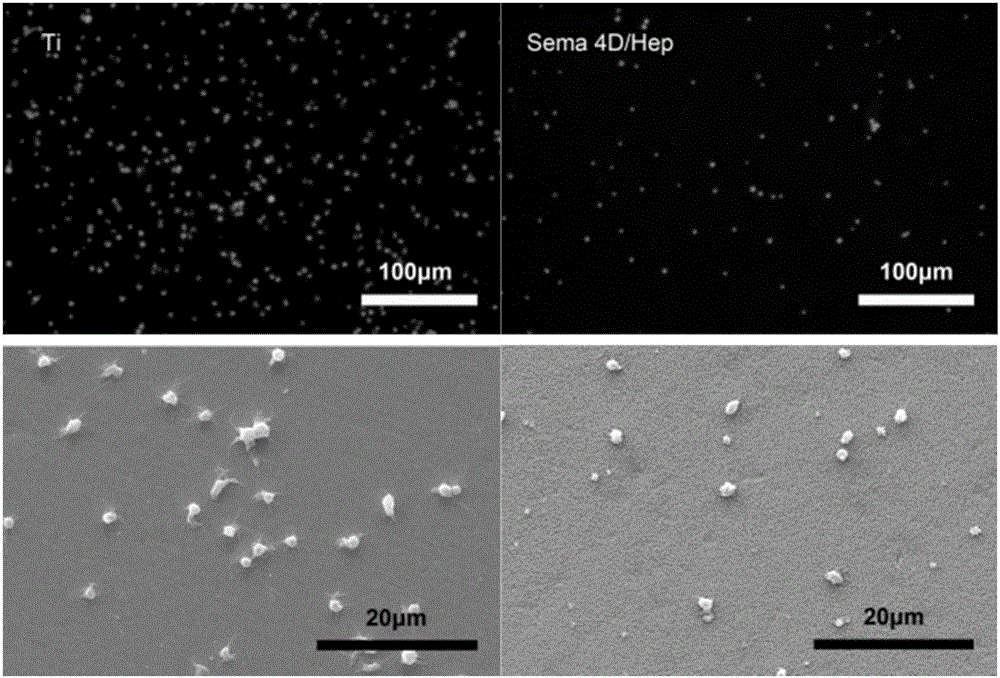

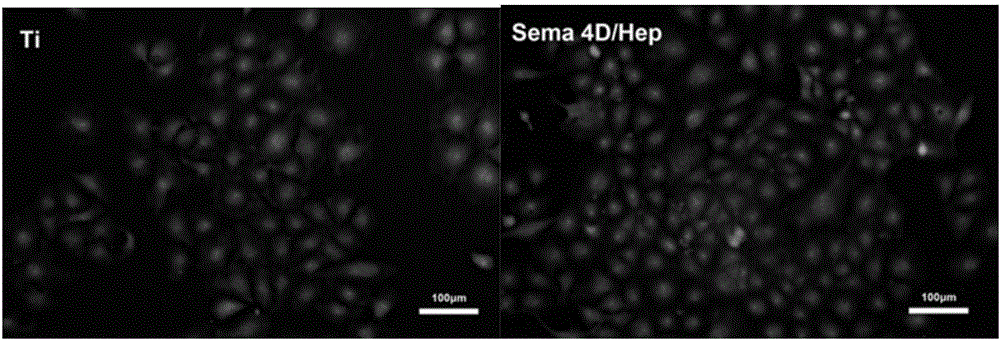

Image

Examples

Embodiment 1

[0044] A method for constructing a Sema 4D / Heparin microenvironment on the surface of a cardiovascular implant material, comprising the following steps:

[0045] A. Alkali activation

[0046] After the pure titanium is polished and cleaned, it is activated with 1mol / L NaOH for 12 hours, after ultrasonic cleaning with single distilled water, it is immersed in double distilled water, and reacted at 80°C for 12 hours, after ultrasonic cleaning with single distilled water, it is dried for later use;

[0047] B. Surface amination

[0048] The alkali-activated sample in step A was immersed in 2.5mg / ml polylysine (PLL, MW 150-300KDa) at 4°C for 12h, washed with phosphate buffer and then used;

[0049] C, Preparation of Sema 4D / Heparin complex

[0050] Mix Sema 4D with a concentration of 50ng / ml and Heparin with a concentration of 5mg / ml in equal volumes, and react at 37°C for 1h;

[0051] D. Sema 4D / Heparin fixed

[0052] Soak the sample in step B in the complex prepared in step ...

Embodiment 2

[0054]A method for constructing a Sema 4D / Heparin microenvironment on the surface of a cardiovascular implant material, comprising the following steps:

[0055] A. Alkaline activation

[0056] After the pure titanium is polished and cleaned, it is activated with 4mol / L NaOH for 16 hours. After ultrasonic cleaning with single distilled water, it is immersed in double distilled water. It is reacted at 80°C for 12 hours. After ultrasonic cleaning with single distilled water, it is dried for later use;

[0057] B. Surface amination

[0058] The alkali-activated sample in step A was immersed in 2.5mg / ml polylysine (PLL, MW 150-300KDa) at 4°C for 12h, washed with phosphate buffer and then used;

[0059] C, Preparation of Sema 4D / Heparin complex

[0060] Mix Sema 4D with a concentration of 200ng / ml and Heparin with a concentration of 8mg / ml in equal volumes, and react at 37°C for 3h;

[0061] D. Sema 4D / Heparin fixed

[0062] Soak the sample in step B in the complex prepared in s...

Embodiment 3

[0064] A method for constructing a Sema 4D / Heparin microenvironment on the surface of a cardiovascular implant material, comprising the following steps:

[0065] A. Alkaline activation

[0066] After the pure titanium is polished and cleaned, it is activated with 2mol / L NaOH for 10 hours, after ultrasonic cleaning with single distilled water, it is immersed in double distilled water, reacted at 80°C for 12 hours, after ultrasonic cleaning with single distilled water, it is dried for later use;

[0067] B. Surface amination

[0068] The alkali-activated sample in step A was immersed in 2.5mg / ml polylysine (PLL, MW 150-300KDa) at 4°C for 12h, washed with phosphate buffer and then used;

[0069] C, Preparation of Sema 4D / Heparin complex

[0070] Mix Sema 4D with a concentration of 400ng / ml and Heparin with a concentration of 10mg / ml in equal volumes, and react at 37°C for 2h;

[0071] D. Sema 4D / Heparin fixed

[0072] Soak the sample in step B in the complex prepared in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com