Preparation method of freeze-dried human thrombin

A technology of human thrombin and human prothrombin, applied in the field of preparation of freeze-dried human thrombin, which can solve the problems of turbidity of thrombin and low yield of target substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

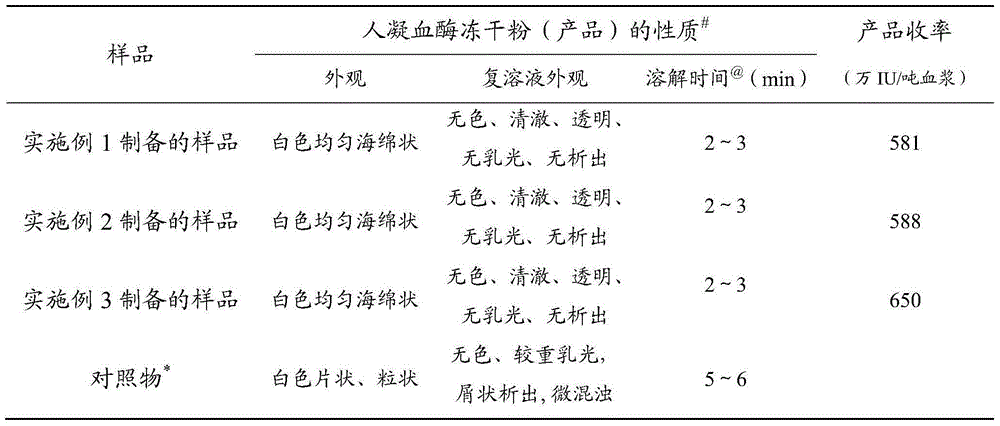

Examples

Embodiment 1

[0038] Step 1, according to the dilution ratio of 1:9, put 1.0kg of Fr.III precipitate into 9kg of HAc-NaAc buffer solution (pH value 5.00, 10°C), stir at a constant speed for 4 hours to fully dissolve, and then add silicon The alginate was stirred for 30 minutes, and then press-filtered at the same temperature to obtain about 0.81 kg of prothrombin precipitate.

[0039] Step 2, according to the dilution ratio of 1:4, put 0.81kg of prothrombin precipitate into 3.24kg Tris-HCL buffer solution (pH value is 6.50, 10°C), stir gently for 4 hours to fully dissolve and obtain a uniform suspension;

[0040] Step 3, add 0.5M CaCl to the above suspension 2 The solution was incubated at 15°C for 10 hours to activate prothrombin into thrombin;

[0041] Step 4, add PEG solution to the suspension after the above activation, stir for 1 hour, press filter, collect the supernatant, then use a 0.45 μm filter element for clarification and filtration, and collect 5.2 kg of filtrate;

[0042] S...

Embodiment 2

[0053] Step 1, according to the dilution ratio of 1:9, put 7.1kg of Fr.III precipitate into 63.9kg of HAc-NaAc buffer solution (pH value is 5.00, 10°C), stir at a constant speed for 4 hours to fully dissolve; add diatom Stir with soil for 30 minutes, then press filter at the same temperature to obtain about 6.2kg of prothrombin precipitate.

[0054] Step 2: According to the dilution ratio of 1:4, put 6.2kg of prothrombin precipitate into 24.8kg of Tris-HCL buffer solution (pH value is 6.50, 10°C), stir gently for 4 hours to fully dissolve;

[0055] Steps 3, 4 and 5 are the same as in Example 1 to obtain 39.2 kg of solution after S / D inactivation;

[0056] Step 6, add pre-balanced SP-Sephadex C-50 ion exchange resin to the solution after S / D inactivation, stir slowly for 2 hours, then filter with a sieve to collect the resin; then use 0.20M sodium chloride Tris -HCl buffer solution for washing; then use 0.6M sodium chloride Tris-HCl buffer solution for elution, and collect 10....

Embodiment 3

[0066] Step 1, according to the dilution ratio of 1:15, put 7.5kg of Fr.III precipitate into 112.5kg of HAc-NaAc buffer (pH value is 5.50, 15°C), stir at a constant speed for 2 hours to fully dissolve; add diatom Stir with soil for 30 minutes, then press filter to obtain about 5.6kg of prothrombin precipitate.

[0067] Step 2, according to the dilution ratio of 1:5, put 5.6kg of prothrombin precipitate into 28kg of Tris-HCL buffer solution (pH value is 7.50, 30°C), stir gently for 2 hours to fully dissolve;

[0068] Step 3, add 0.5M CaCl to the above solution 2 The solution was incubated at 30°C for 5 hours to activate prothrombin into thrombin;

[0069] Steps 4 and 5 are the same as in Example 2.

[0070] Step 6, add pre-balanced SP-Sephadex C-50 ion exchange resin to the solution after S / D inactivation, stir slowly for 1 hour, then filter with a sieve to collect the resin; then use 0.10M sodium chloride Tris -HCl buffer solution for washing; then use 1.0M sodium chloride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com