Photosensitive composition for permanent films, resist material and coating film

A photosensitive composition and permanent film technology, which is applied to photosensitive materials, coatings, optics and other directions for optomechanical equipment, can solve problems such as permanent film contamination, and achieve non-susceptibility to contamination, excellent moisture absorption and contamination resistance. , Excellent hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0098] Hereinafter, although an Example etc. are given and this invention is demonstrated in detail, this invention is not limited to these Examples etc. Hereinafter, unless otherwise specified, "parts" and "%" are based on mass.

[0099]

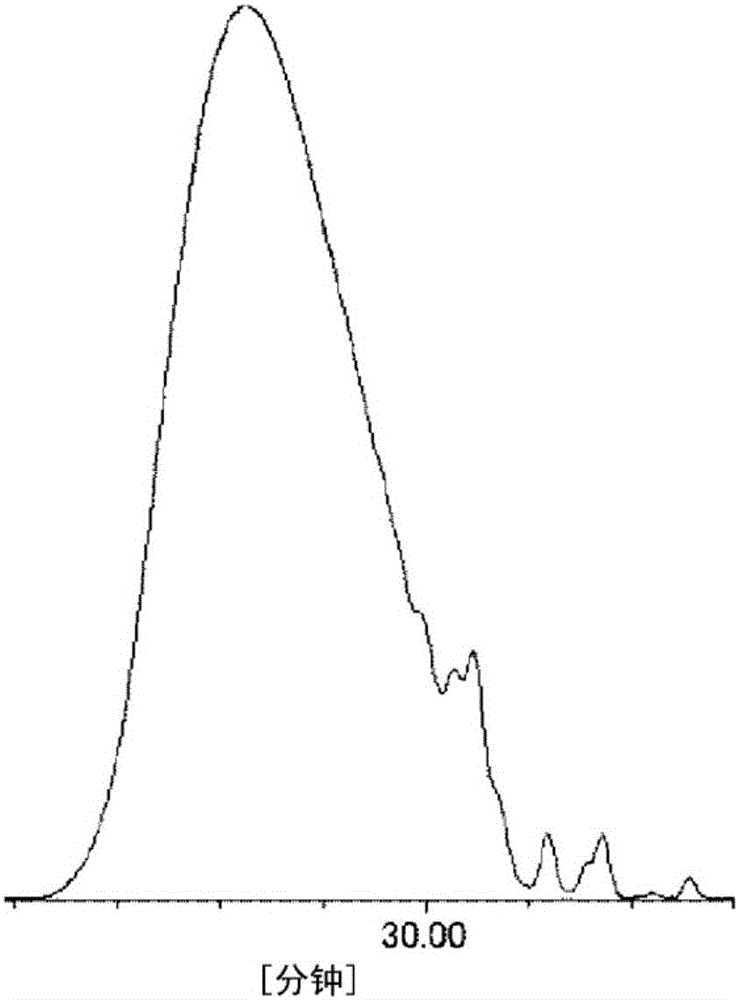

[0100] The molecular weight distribution of the resin composition is measured by GPC and the following measurement conditions by the polystyrene standard method.

[0101] (Measurement conditions of GPC)

[0102] Measuring device: "HLC-8220GPC" manufactured by TOSOH CORPORATION,

[0103] Column: "Shodex KF802" manufactured by Showa Denko Co., Ltd. + "Shodex KF802" manufactured by Showa Denko Co., Ltd. + "ShodexKF803" manufactured by Showa Denko Co., Ltd. + "Shodex KF804" manufactured by Showa Denko Co., Ltd.

[0104] Detector: RI,

[0105] Determination conditions: column temperature 40°C

[0106] Developing solvent Tetrahydrofuran (THF)

[0107] Flow rate 1.0mL / min

[0108] Sample: a substance (5 μL) obtained by filtering a ...

Synthetic example 1

[0137] In the four-necked flask of 1L capacity that thermometer, cooling tube, agitator are installed, drop into 1-naphthol 144g (1.0 mole), methyl isobutyl ketone 400g, water 96g and 92% paraformaldehyde 27.7g (0.85 Moore). Next, 4.8 g of an aqueous solution of p-toluenesulfonic acid adjusted to a concentration of 50% was added to the four-necked flask while stirring. The amount of water in the reaction system was 69.9 parts by mass relative to 100 parts by mass of 1-naphthol. Thereafter, the temperature was raised to 80° C. while stirring the solution in the system, and the reaction was carried out for 2 hours. During the reaction, the organic layer and the water layer will not form a completely compatible "homogeneous" state, but a "heterogeneous" state. After the reaction, the solution in the system was moved to a separatory funnel, and the water layer was separated and removed from the organic layer. Next, after washing with water until the washing water became neutral...

Synthetic example 2

[0139] In a four-neck flask with a capacity of 1 L equipped with a thermometer, a cooling tube, and a stirrer, 144 g (1.0 mole) of 1-naphthol, 2.2 g (0.02 mole) of o-cresol, 400 g of 1-butanol, 96 g of water and 92 % paraformaldehyde 27.7 g (0.85 moles). Next, 4.8 g of an aqueous solution of p-toluenesulfonic acid adjusted to a concentration of 50% was added to the four-necked flask while stirring. The amount of water in the reaction system was 69.9 parts by mass relative to 100 parts by mass of 1-naphthol. Thereafter, the temperature was raised to 80° C. while stirring the solution in the system, and the reaction was carried out for 2 hours. During the reaction, the organic layer and the water layer will not form a completely compatible "homogeneous" state, but a "heterogeneous" state. After the reaction, the solution in the system was moved to a separatory funnel, and the water layer was separated and removed from the organic layer. Next, after washing with water until th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com