Heat exchanger tube, heat exchanger, and brazing paste

A technology of heat exchangers and brazing, which is applied in the direction of heat exchange equipment, indirect heat exchangers, heat exchanger types, etc., can solve problems such as difficulty in reducing manufacturing costs and material costs, and achieve easy lightweight and excellent corrosion resistance , the effect of thinning the wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

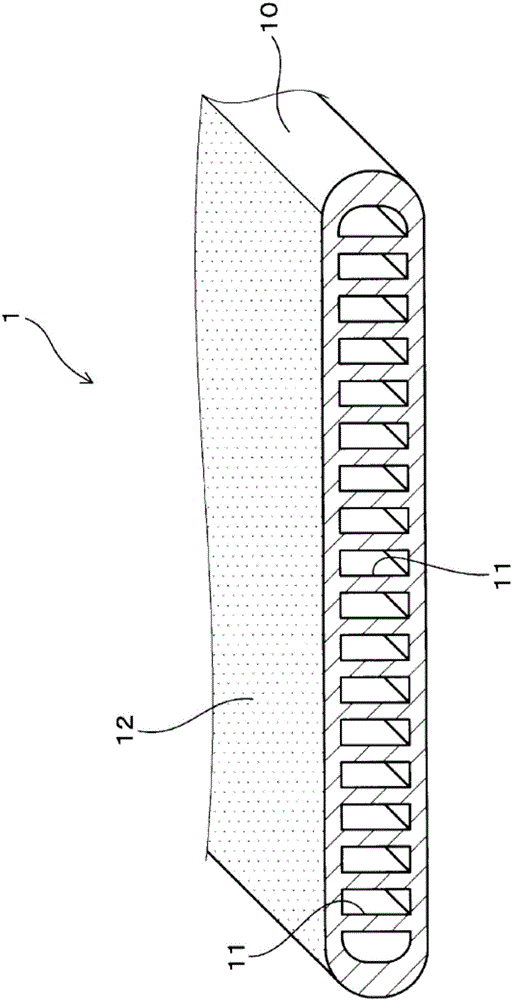

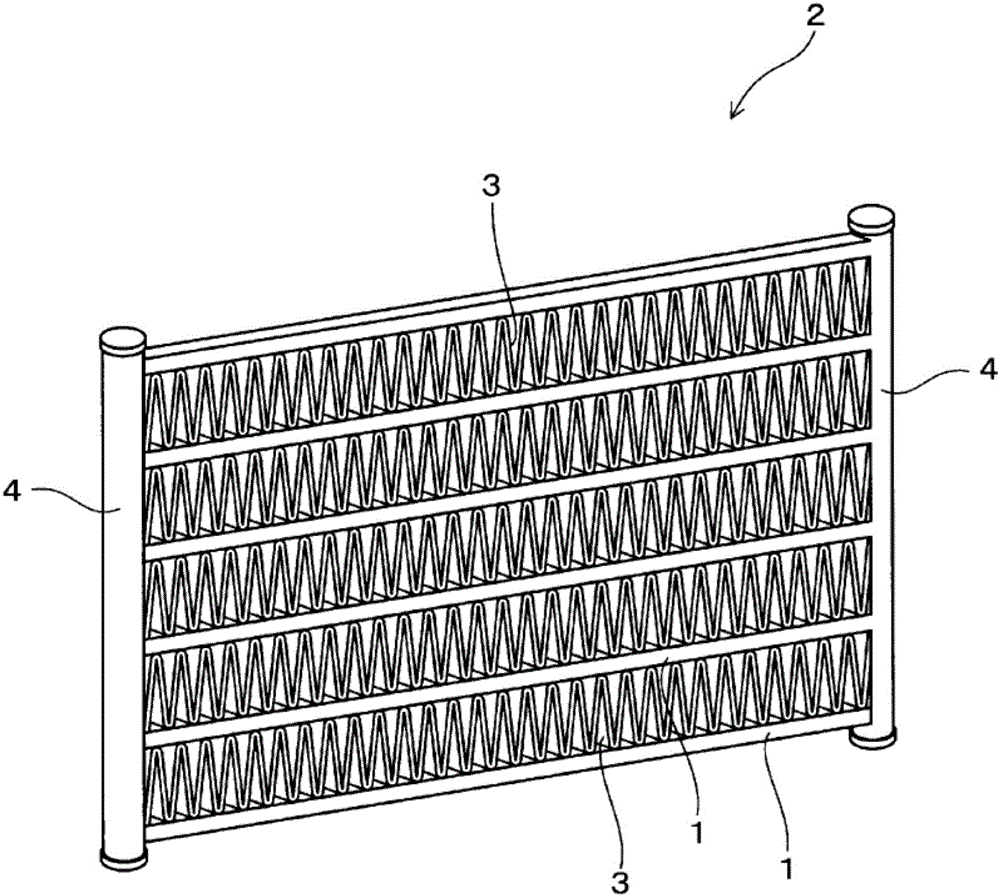

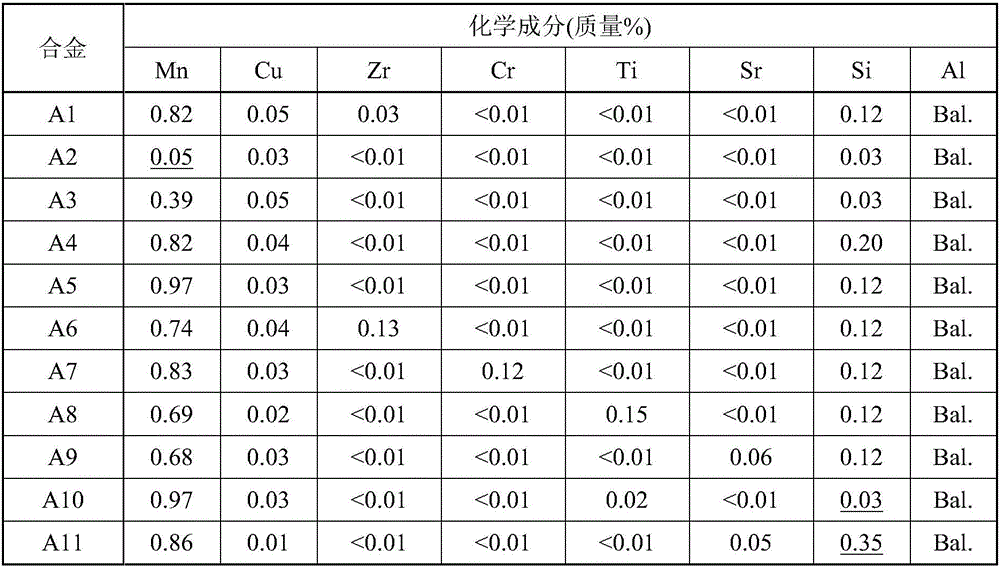

[0110] Examples of the heat exchanger tube described above and a heat exchanger manufactured using the above heat exchanger tube will be described below. In this example, 11 types of alloys A1 to A11 having the chemical compositions shown in Table 1 were used to produce figure 1 Tube 1 shown. Afterwards, use the resulting tube 1 assembly figure 2 For the heat exchangers 2 shown, the brazing workability and corrosion resistance of the obtained 11 types of heat exchangers 2 were evaluated. The details will be described below.

[0111]

[0112] The material having the chemical composition shown in Table 1 was heated at 600° C. for 10 hours to perform a homogenization treatment. After the homogenization treatment, the billet was cooled to room temperature, and then heated to 450° C. for hot extrusion. above, such as figure 1 As shown, the pipe main body 10 having a flat cross section perpendicular to the extrusion direction and including a plurality of refrigerant passages...

Embodiment 2

[0134] This example is an example of the heat exchanger 2 in which the content of each component in the coating film 12 is changed by changing the composition of the paste for forming the coating film 12 . In this example, the pipe main body 10 was fabricated using the alloy A1 in Example 1, and the coating films B1 to B25 having the compositions shown in Table 3 were formed to obtain the pipe 1. switch 2. Using the obtained 25 types of heat exchangers 2 (test bodies 21 to 45), the brazability and corrosion resistance were evaluated in the same manner as in Example 1. Table 4 shows the results.

[0135] As can be seen from Table 3 and Table 4, since the test bodies 21 to 35 used the coating films B1 to B15 having the above-mentioned specific composition, both brazing properties and corrosion resistance showed favorable results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com