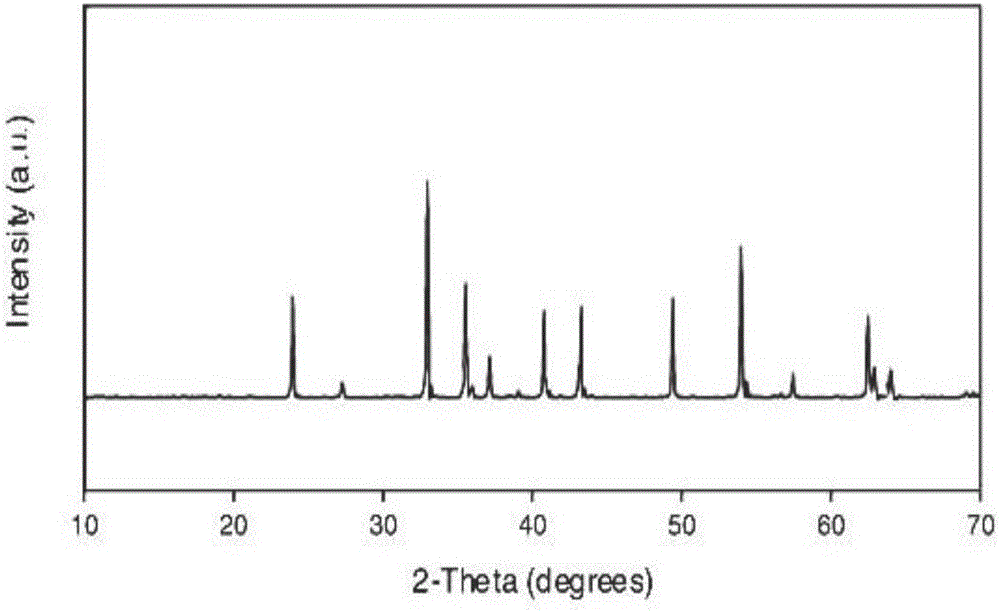

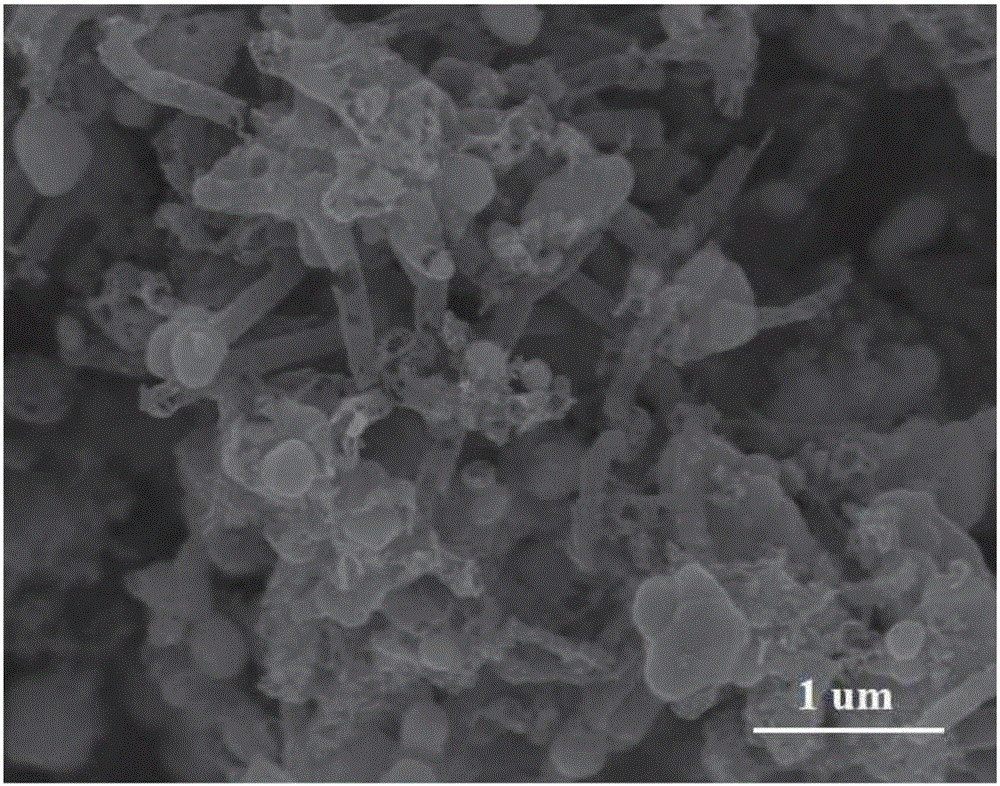

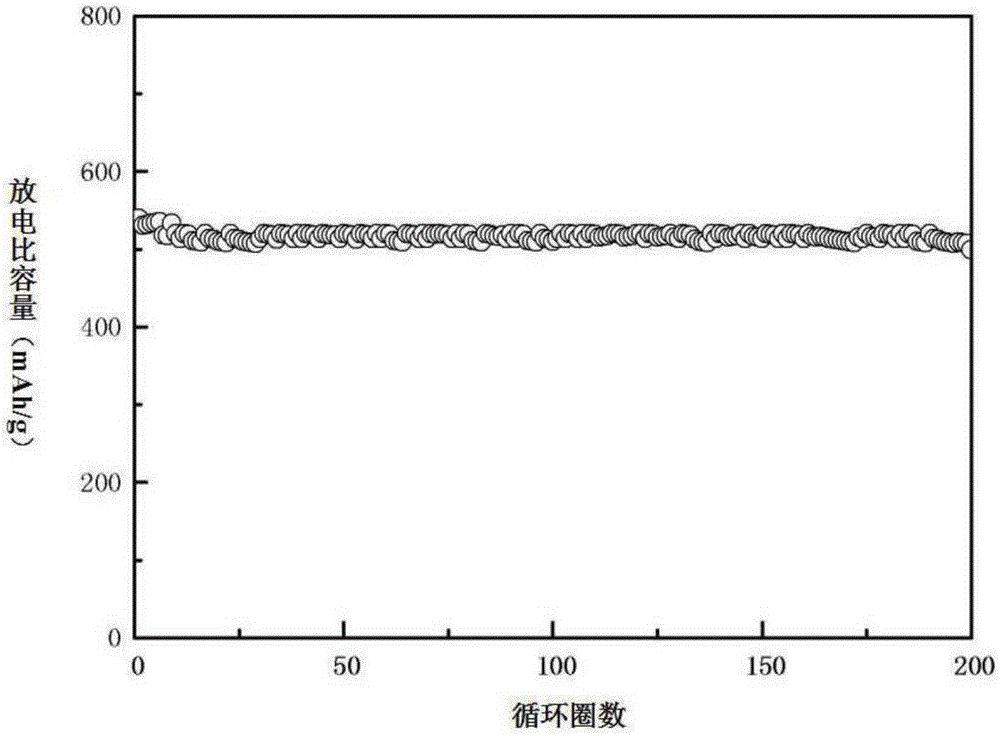

Carbon-coated NiTiO3/CNT negative electrode material, preparation method and application

A negative electrode material and carbon coating technology, which is applied in the field of sodium ion battery negative electrode material preparation, can solve the problems of less research on sodium ion battery negative electrode materials, inability to meet high specific capacity materials, volume expansion, etc., and achieves broad industrial application prospects, good Effect of rate capability and cycle stability, high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Multi-walled carbon nanotubes (1-2um in length and 60-100nm in diameter) were treated in 8M concentrated nitric acid solution for 12h, then ultrasonically washed with absolute ethanol and deionized water for 30min, filtered and dried for later use.

[0069] Add 75 mg of acid-treated carbon nanotubes to 50 mL of absolute ethanol, and ultrasonically treat for 30 minutes to obtain a suspension of carbon nanotubes. Then, 500 mg of PVP (molecular weight: 10100) and 4.5 mL of tetrabutyl titanate were sequentially added to the carbon nanotube suspension, and stirred thoroughly for 1 h to obtain a mixed suspension. 3.291 g of nickel acetate tetrahydrate (titanium / nickel molar ratio 1:1) was dissolved in 30 mL of deionized water to obtain a nickel acetate solution. It was slowly added dropwise to the above mixed suspension, and after continuous stirring for 4 hours, it was transferred to an autoclave and reacted at 200°C for 18 hours. The reaction precipitate was repeatedly was...

Embodiment 2

[0076] Take 75 mg of carbon nanotubes that have been acid-treated in advance (see Example 1 for the treatment method), add them to 50 mL of absolute ethanol, and perform ultrasonic treatment for 30 minutes to obtain a suspension of carbon nanotubes. Then, 600 mg of PVP (molecular weight: 10100) and 4.5 mL of tetrabutyl titanate were sequentially added to the carbon nanotube suspension, and stirred thoroughly for 1 h to obtain a mixed suspension. 3.291 g of nickel acetate tetrahydrate (titanium / nickel molar ratio 1:1) was dissolved in 40 mL of deionized water to obtain a nickel acetate solution. It was slowly added dropwise to the above mixed suspension, and after continuous stirring for 4 hours, it was transferred to an autoclave and reacted at 200°C for 18 hours. The reaction precipitate was repeatedly washed with absolute ethanol and deionized water, filtered three times, then vacuum-dried at 60°C for 12 hours, and finally the material was placed in a tube furnace for heat t...

Embodiment 3

[0079]Take 70 mg of carbon nanotubes that have been acid-treated in advance (see Example 1 for the treatment method), add them to 50 mL of absolute ethanol, and ultrasonicate for 30 minutes to obtain a suspension of carbon nanotubes. Then, 500 mg of PVP (molecular weight: 10100) and 3.5 mL of tetrabutyl titanate were sequentially added to the carbon nanotube suspension, and fully stirred for 2 hours to obtain a mixed suspension. 2.559 g of nickel acetate tetrahydrate (titanium / nickel molar ratio 1:1) was dissolved in 30 mL of deionized water to obtain a nickel acetate solution. It was slowly added dropwise to the above mixed suspension, and after continuous stirring for 3 hours, it was transferred to an autoclave and reacted at 200°C for 18 hours. The reaction precipitate was repeatedly washed with absolute ethanol and deionized water, filtered three times, then vacuum-dried at 60°C for 12 hours, and finally the material was placed in a tube furnace for heat treatment under an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com