Low temperature inorganic fused salt aluminium ion supercapacitor battery and preparation method therefor

A supercapacitor battery and aluminum ion technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid capacitor electrolytes, hybrid/electric double layer capacitors, etc., can solve problems such as potential safety hazards, reduce preparation costs, reduce internal resistance, and be cheap Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

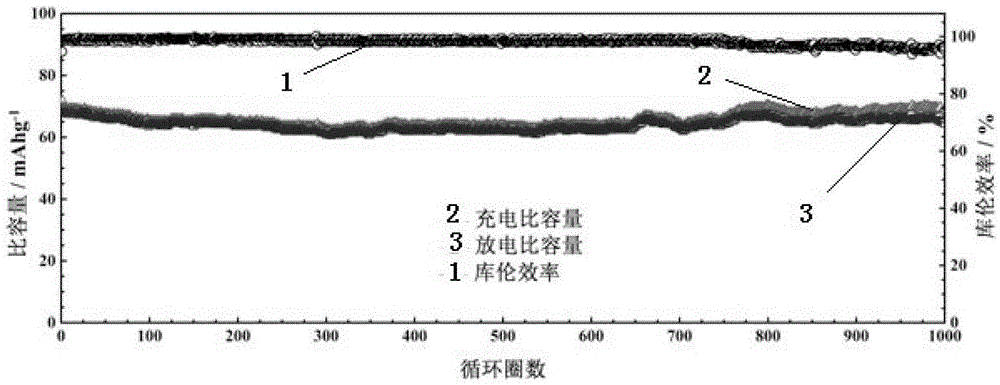

Examples

Embodiment 1

[0027] Process the graphite and titanium sulfide (mass ratio 1:1) composite block into a square sheet-shaped block with a side length of 1000mm and a thickness of 60mm, and process a thread with a depth of 100mm and a diameter of 50mm on one side of the sheet, and pass A stainless steel rod with a diameter of 50 mm was screwed as the conductive rod of the positive electrode composite material. Then wrap a layer of glass fiber diaphragm on the positive electrode composite material, and then build a cubic electrolytic cell with a side length of 1200 mm and a depth of 1200 mm as a reaction vessel. Select an aluminum ingot with a purity greater than 99%, process it into a square sheet with a side length of 1000mm and a thickness of 50mm, and process a thread with a depth of 100mm and a diameter of 30mm on one side of the sheet, and connect a stainless steel with a diameter of 30mm through the thread The rod serves as the conductive rod of the negative aluminum sheet. NaCl:AlCl in...

Embodiment 2

[0029] Process the graphite and titanium sulfide (mass ratio 1:1) composite block into a square sheet-shaped block with a side length of 1000mm and a thickness of 60mm, and process a thread with a depth of 100mm and a diameter of 50mm on one side of the sheet, and pass A stainless steel rod with a diameter of 50 mm was screwed as the conductive rod of the positive electrode composite material. Then wrap a layer of glass fiber diaphragm on the positive electrode composite material, and then build a cubic electrolytic cell with a side length of 1200 mm and a depth of 1200 mm as a reaction vessel. Select an aluminum ingot with a purity greater than 99%, process it into a square sheet with a side length of 1000mm and a thickness of 50mm, and process a thread with a depth of 100mm and a diameter of 30mm on one side of the sheet, and connect a stainless steel with a diameter of 30mm through the thread The rod serves as the conductive rod of the negative aluminum sheet. LiCl:AlCl at...

Embodiment 3

[0031] Process the graphite and titanium sulfide (mass ratio 1:1) composite block into a square sheet-shaped block with a side length of 1000mm and a thickness of 60mm, and process a thread with a depth of 100mm and a diameter of 50mm on one side of the sheet, and pass A stainless steel rod with a diameter of 50 mm was screwed as the conductive rod of the positive electrode composite material. Then wrap a layer of glass fiber diaphragm on the positive electrode composite material, and then build a cubic electrolytic cell with a side length of 1200 mm and a depth of 1200 mm as a reaction vessel. Select an aluminum ingot with a purity greater than 99%, process it into a square sheet with a side length of 1000mm and a thickness of 50mm, and process a thread with a depth of 100mm and a diameter of 30mm on one side of the sheet, and connect a stainless steel with a diameter of 30mm through the thread The rod serves as the conductive rod of the negative aluminum sheet. KCl:AlCl at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com