Electroplating selenium plating solution, and lithium-selenium battery and positive electrode material thereof

A battery cathode and plating solution technology, applied in battery electrodes, electrode manufacturing, secondary batteries, etc., can solve the problems of inability to fully utilize active components to protect active materials, cumbersome preparation methods, etc., and achieve excellent charge-discharge specific capacity and cycle. performance, the effect of improving charge-discharge specific capacity and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The preparation method of the above-mentioned plating solution of the present invention is preferably specifically:

[0059] The above-mentioned parts by weight of selenous acid or selenite, electrolyte salt, pH regulator, pH buffer, surface active agent and water are mixed to obtain a plating solution.

[0060] The present invention does not limit the specific way of mixing, and the way known to those skilled in the art is enough. The present invention does not limit the mixing method. Preferably, selenous acid or selenite is mixed with water, and then mixed with electrolyte salt, pH regulator, pH buffer, and surfactant.

[0061] The present invention provides a kind of preparation method of lithium selenium battery cathode material, comprises the following steps:

[0062] A) mixing selenous acid or selenite, electrolyte salt, pH regulator, pH buffer, surfactant and water to obtain a mixed solution;

[0063] B) Electroplating the mixed solution on the substrate at a ...

Embodiment 1

[0095] Using an electronic balance with an accuracy of 0.00001g to weigh 1.11g of selenium dioxide; using an electronic balance with an accuracy of 0.00001g to weigh 1.86g of potassium chloride; using an electronic balance with an accuracy of 0.00001g to weigh 0.02g of potassium hydroxide Utilize the electronic balance that precision is 0.00001g to weigh the polyvinylpyrrolidone of 0.1g; Utilize the electronic balance that precision is 0.00001g to weigh the potassium hydrogen phthalate of 3.75g. The medicines weighed above were mixed fully and evenly in a square mouth beaker with a capacity of 200ml adding 100ml deionized water successively to prepare the electroplating solution.

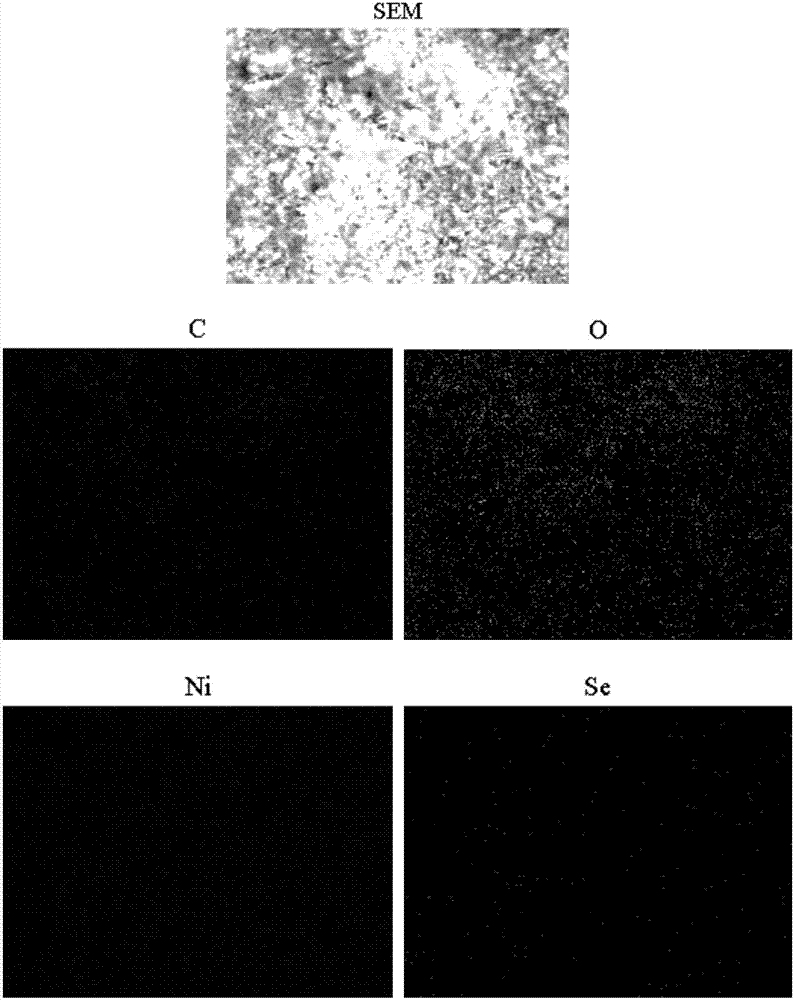

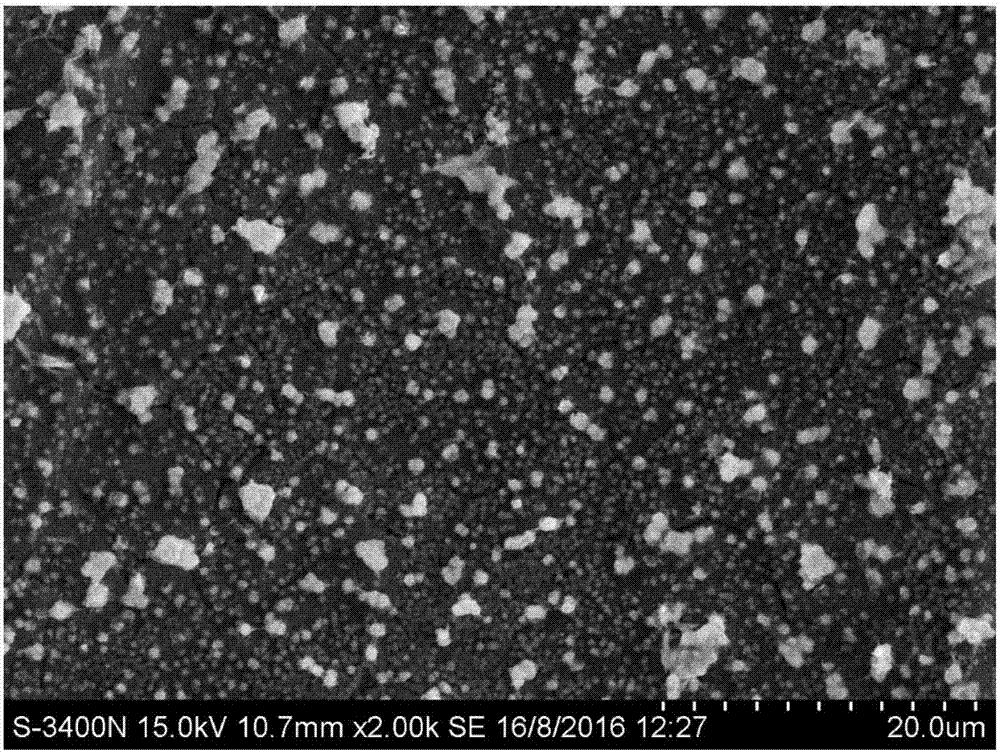

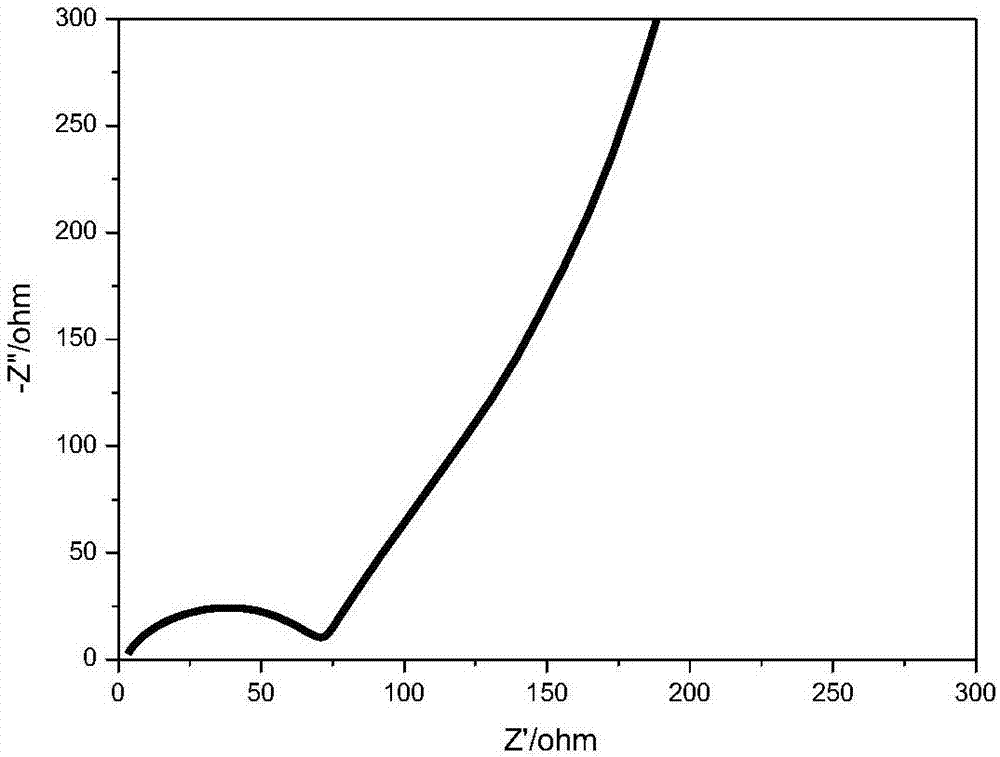

[0096] Sonicate the 0.5mm thick, long strip-shaped nickel foam of 6*1cm in acetone for 10 minutes, in ethanol for 10 minutes, in the prepared 3mol / L dilute hydrochloric acid solution for 10 minutes, soak in the above hydrochloric acid for 30 minutes, Vacuum drying for 24 hours to obtain a foamed nic...

Embodiment 2

[0100] Using an electronic balance with an accuracy of 0.001g to weigh 1.11g of selenium dioxide; using an electronic balance with an accuracy of 0.001g to weigh 1.86g of potassium chloride; using an electronic balance with an accuracy of 0.001g to weigh 0.02g of potassium hydroxide Utilize the polyethylene oxide that precision is the electronic balance of 0.00001g to weigh 0.05g; Utilize the electronic balance that precision is 0.00001g to weigh the citric acid of 2.15g.

[0101] The medicines weighed above are mixed fully and evenly in a square mouth beaker with a capacity of 200ml adding 100ml deionized water successively to prepare the electroplating solution;

[0102] Sonicate the 0.5mm thick, long strip-shaped nickel foam of 6*1cm in acetone for 10 minutes, in ethanol for 10 minutes, in the prepared 3mol / L dilute hydrochloric acid solution for 10 minutes, soak in the above hydrochloric acid for 30 minutes, Vacuum drying for 24 hours to obtain a foamed nickel substrate wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com