Preparation method and application of potassium ion battery negative electrode energy storage material

A battery negative electrode and energy storage material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as low specific capacity, cycle stability, poor rate performance, and unsatisfactory electrochemical performance, and achieve Effects of high specific capacity, good rate performance, and excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

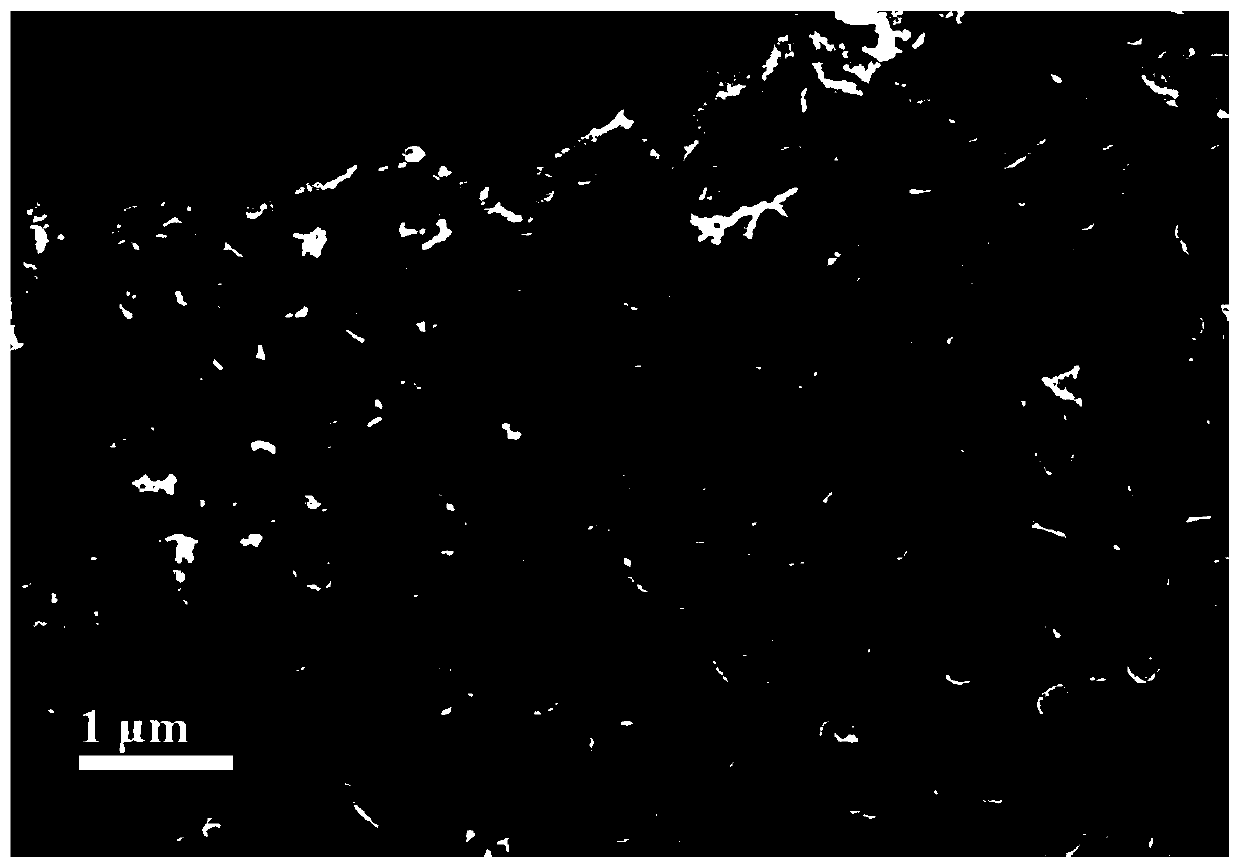

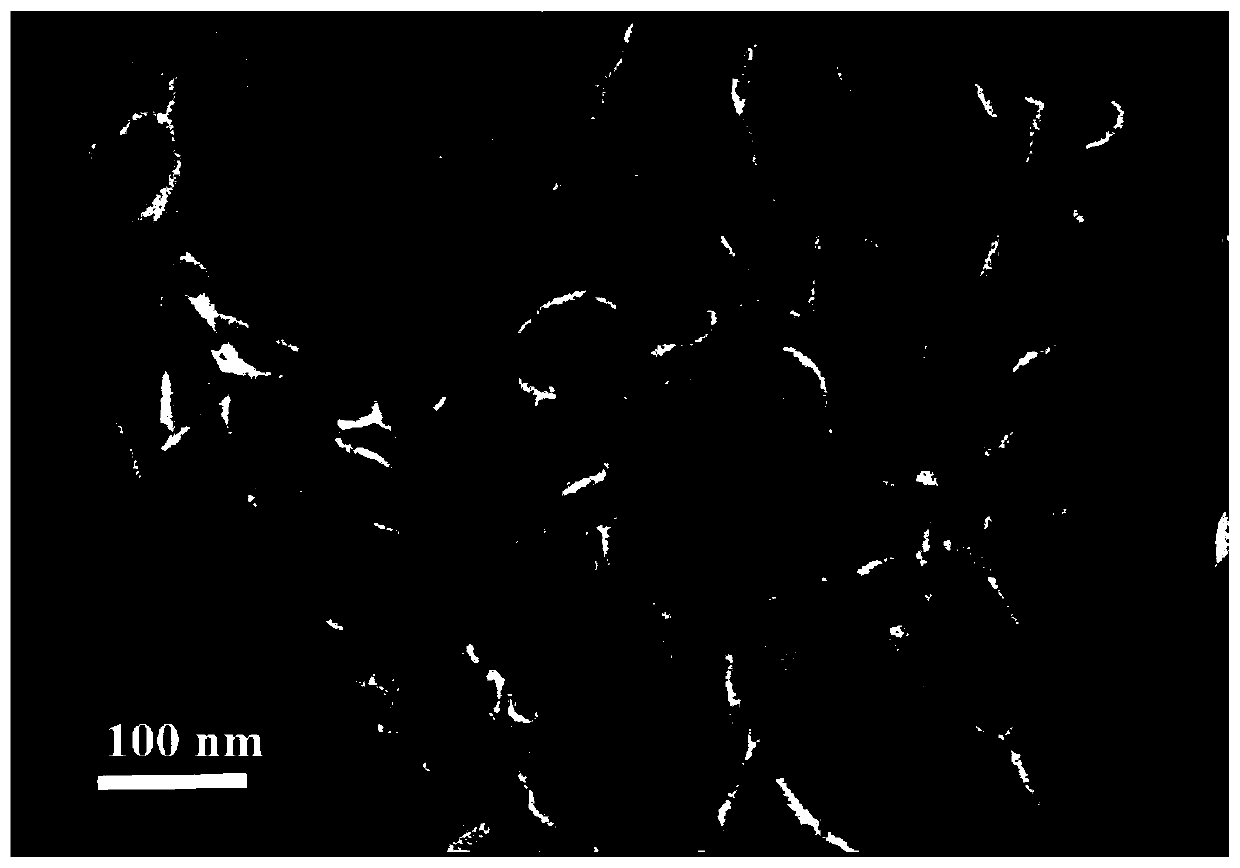

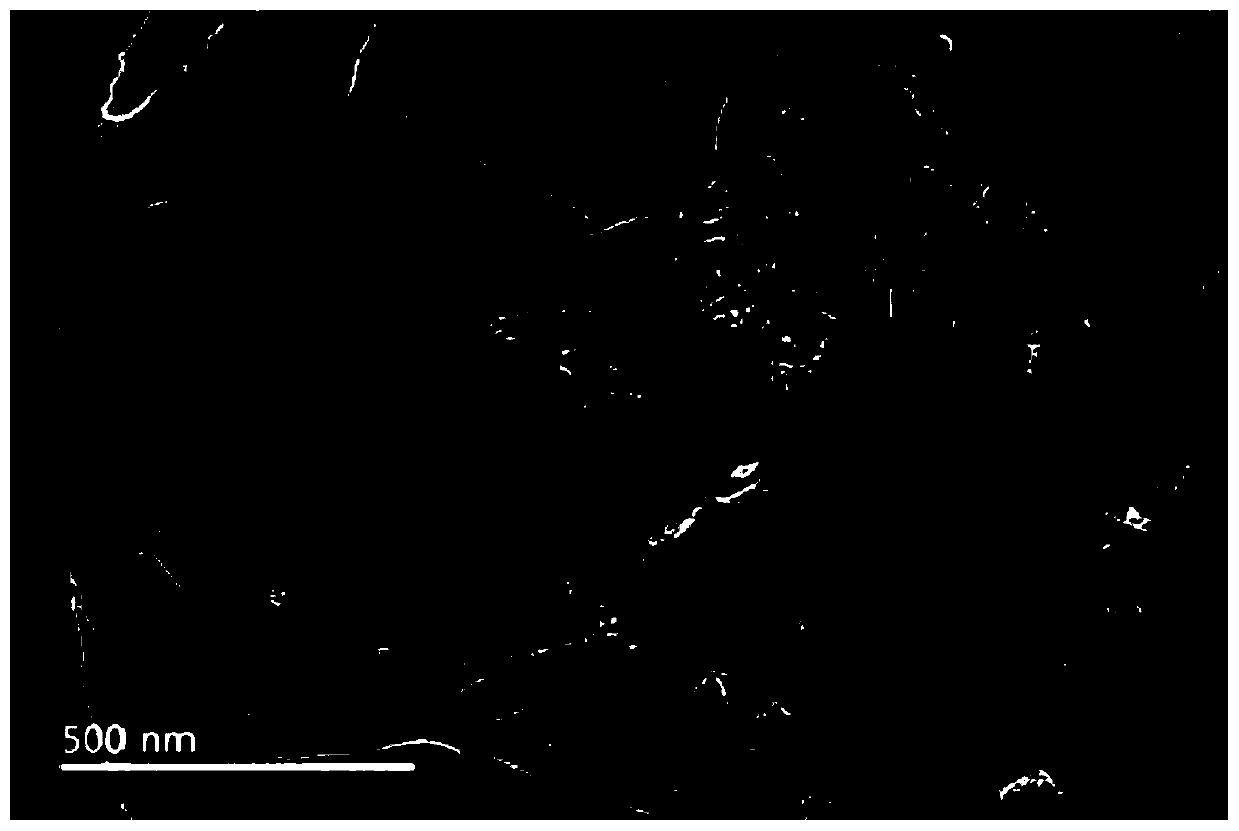

Image

Examples

Embodiment 1

[0039] A kind of preparation method of negative electrode energy storage material of potassium ion battery, is characterized in that, specifically comprises the following steps:

[0040] (1) Collect polymer water-absorbent resin particles, weigh 3g into a clean beaker, add 60ml of distilled water, and use a shaker to shake for 1 hour. After shaking, transfer it to a polytetrafluoroethylene-lined reaction kettle, and then Incubate for 3 hours under the reaction condition of 150°C, and the pretreated superabsorbent resin is converted into a hydrogel that tends to be integrated;

[0041] (2) Then transfer the hydrogel to the refrigerator and freeze it into an ice gel for 8 hours, and finally dry and sublimate the solid ice by a freeze drying machine (that is, remove the solvent in the original aqueous solution) to obtain a dry airgel precursor;

[0042](3) Transfer the dried airgel precursor to a tube furnace and calcine at high temperature. The calcination parameters are set as ...

Embodiment 2

[0049] A kind of preparation method of negative electrode energy storage material of potassium ion battery, is characterized in that, specifically comprises the following steps:

[0050] (1) Collect polymer water-absorbent resin particles, weigh 3g into a clean beaker, add 60ml of distilled water, and use a shaker to shake for 1 hour. After shaking, transfer it to a polytetrafluoroethylene-lined reaction kettle, and then Incubate for 3 hours under the reaction condition of 150°C, and the pretreated superabsorbent resin is converted into a hydrogel that tends to be integrated;

[0051] (2) Then transfer the hydrogel to the refrigerator and freeze it into an ice gel for 8 hours, and finally dry and sublimate the solid ice by a freeze drying machine (that is, remove the solvent in the original aqueous solution) to obtain a dry airgel precursor;

[0052] (3) Transfer the dried airgel precursor to a tube furnace and calcine at high temperature. The calcination parameters are set as...

Embodiment 3

[0058] A kind of preparation method of negative electrode energy storage material of potassium ion battery, is characterized in that, specifically comprises the following steps:

[0059] (1) Collect polymer water-absorbent resin particles, weigh 3g into a clean beaker, add 60ml of distilled water, and use a shaker to shake for 1 hour. After shaking, transfer it to a polytetrafluoroethylene-lined reaction kettle, and then Incubate for 3 hours under the reaction condition of 150°C, and the pretreated superabsorbent resin is converted into a hydrogel that tends to be integrated;

[0060] (2) Then transfer the hydrogel to the refrigerator and freeze it into an ice gel for 8 hours, and finally dry and sublimate the solid ice by a freeze drying machine (that is, remove the solvent in the original aqueous solution) to obtain a dry airgel precursor;

[0061] (3) Transfer the dried airgel precursor to a tube furnace and calcine at high temperature. The calcination parameters are set as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com