Method and device for testing heat pipe wick capillary on basis of quantum dots

A test method, quantum dot solution technology, applied in the direction of measuring device, suspension and porous material analysis, surface/boundary effect, etc., can solve the problem that it is difficult to accurately judge the meniscus of capillary flow, affect the accuracy of measurement results, and make capillary accurate Measurement and other issues, to achieve the effect of simple structure, easy cleaning, high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

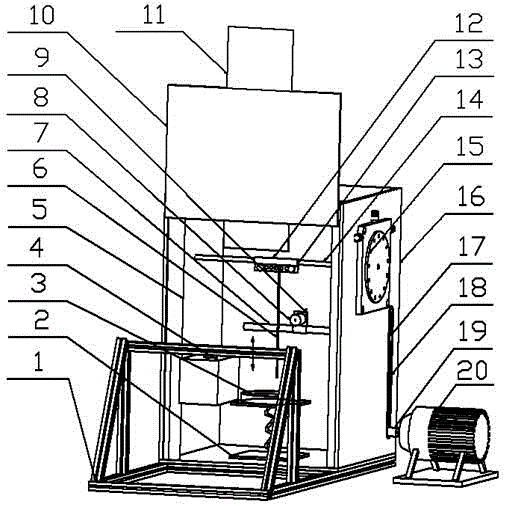

[0047] Based on the braided copper wire matrix with a diameter of 30 μm, chemical deposition-vacuum sintering is used to enhance its capillary capacity, and a liquid-absorbing core with a thickness of 0.5 mm, a width of 1.5 mm, a length of 100 mm, and a porosity of 50% is prepared; figure 1 The capillary capacity of the liquid-absorbent core prepared by the device test;

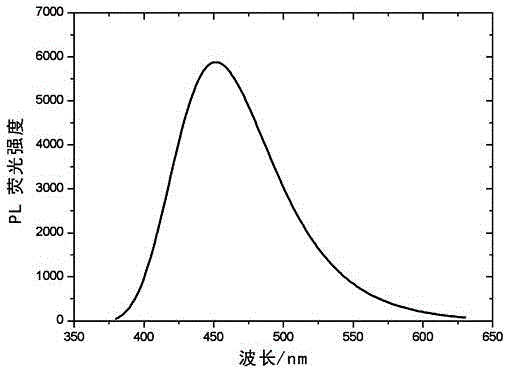

[0048] Using C quantum dots to prepare C quantum dot solution for photosensitive display, the mass concentration of C quantum dot solution is 1%; Utilize Japan Shimadzu fluorescence spectrophotometer RF-6000 to test C quantum dots, the excitation wavelength is 455nm; the emission spectrum is as follows figure 2 shown by figure 2 It can be seen that the emission wavelength is 451nm;

[0049] (1) The angle turntable 15 controls the rotating rod 14 to rotate at an angle of 0°; the C quantum dot solution is added to the container 3, and the height of the lifting platform 2 is adjusted so that the C quantum dot...

Embodiment 2

[0057] Based on copper powder with a diameter of 200 mesh, vacuum sintering is used to enhance its capillary capacity, and it is sintered at 900°C for 30 minutes to prepare a liquid-absorbing core with a thickness of 0.4mm, a width of 10mm, a length of 200mm, and a porosity of 80%. use figure 1 The capillary capacity of the liquid-absorbent core prepared by the device test;

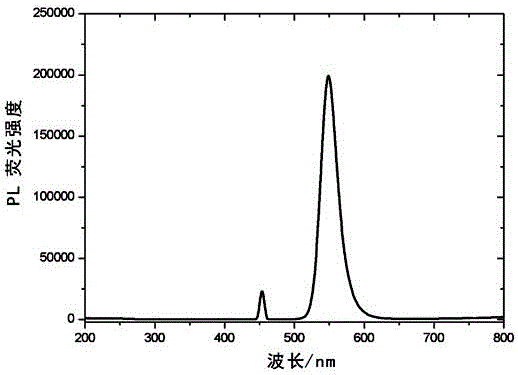

[0058] The quantum dot solution used is a CdSe / ZnS quantum dot aqueous solution, and the mass concentration of the CdSe / ZnS quantum dot solution is 5%; the CdSe / ZnS quantum dot solution is tested with a Shimadzu fluorescence spectrophotometer RF-6000, and the excitation wavelength is 455nm; Spectrum such as image 3 shown by image 3 It can be seen that the emission wavelength is 549nm;

[0059] (1) The angle turntable 15 controls the rotating rod 14 to rotate at an angle of 60°; the CdSe / ZnS quantum dot solution is added to the container 3, and the height of the lifting platform 2 is adjusted so that ...

Embodiment 3

[0066] The difference from Example 1 is that the liquid-absorbing core used in this example is based on a copper wire matrix braided mesh with a diameter of 30um, and its capillary capacity is enhanced by chemical deposition-vacuum sintering. The thickness of the preparation is 0.5mm and the width is 1.5mm. mm, a length of 100mm, and a liquid-absorbent core with a porosity of 65%; the simulated rotation condition of the liquid-absorbent core 6 is 30°; the immersion depth of the liquid-absorbent core 6 is 1.75mm; the mass concentration of C quantum dots used is 3%; capillary test The time is 17min to collect relevant data.

[0067] From the obtained fluorescent image of C quantum dots, it is known that the C quantum dots on the copper wire mesh are excited to emit light obviously, the distribution of luminous intensity is relatively uniform, and there is no obvious dark area. A meniscus boundary that is high in the middle and low on both sides appears.

[0068] The camera 4 re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com