Device for testing stress corrosion behavior of metal material under fluid high pressure

A technology of stress corrosion and metal materials, applied in measuring devices, using stable tension/pressure to test the strength of materials, analyzing materials, etc., can solve the problems of inability to greatly adjust the applied stress, apply electrochemical signals, and relax frame materials , to achieve the effect of avoiding stress conduction, high sealing requirements, simple principle, and reduced requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

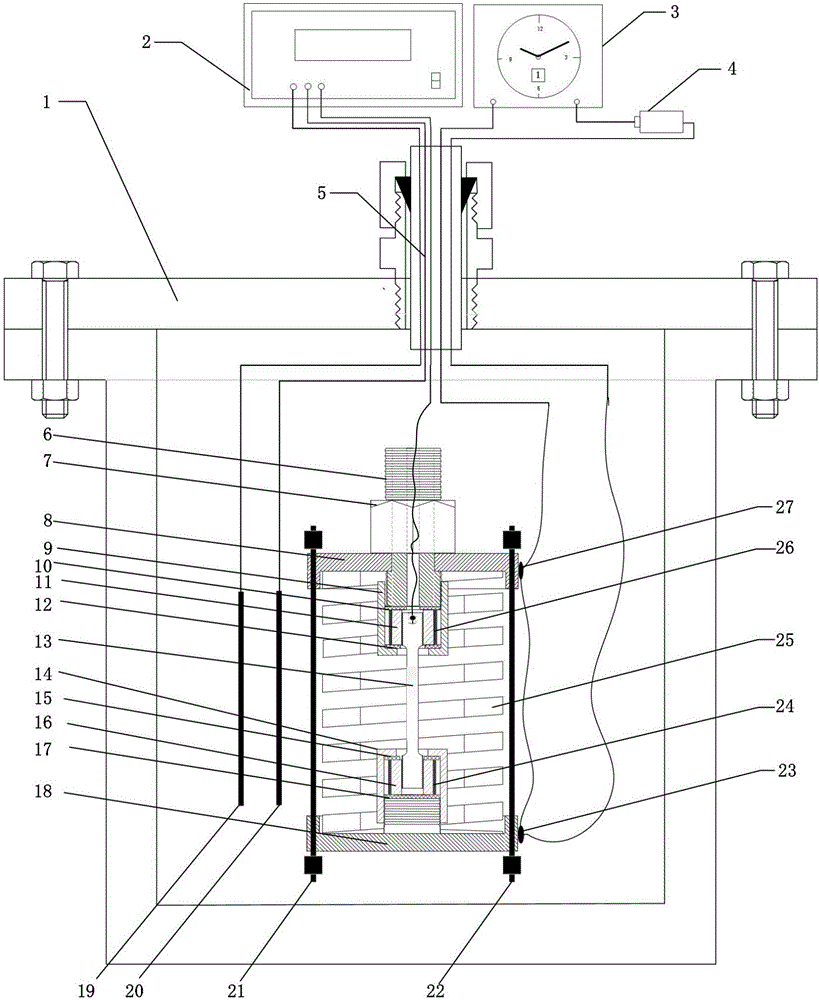

[0032] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0033] The invention provides a device for testing stress corrosion behavior of metal materials under fluid high pressure.

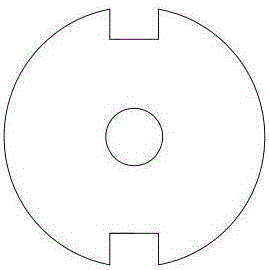

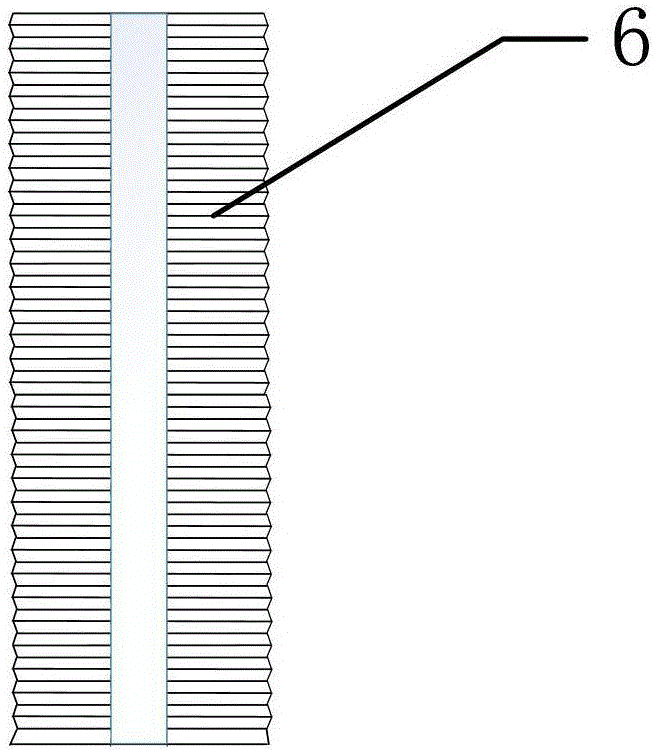

[0034] Such as figure 1 Shown is the schematic diagram of the structure of the device, the lid of the autoclave 1 is equipped with bundled wires 5, which are used to extend the wires of the electrochemical workstation 2, timer 3, and timer power supply 4 outside the autoclave 1 to the inside of the autoclave 1; 6. Loading nut 7, top plate of loading device 8, closed threaded sleeve 19, high-strength insulating circular gasket with holes 10, threaded sleeve 11, high-strength insulating circular gasket 2 12, sample 13, Neck threaded sleeve 2 14, high-strength insulating circular gasket with holes 3 15, threaded sleeve 2 16, high-str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com