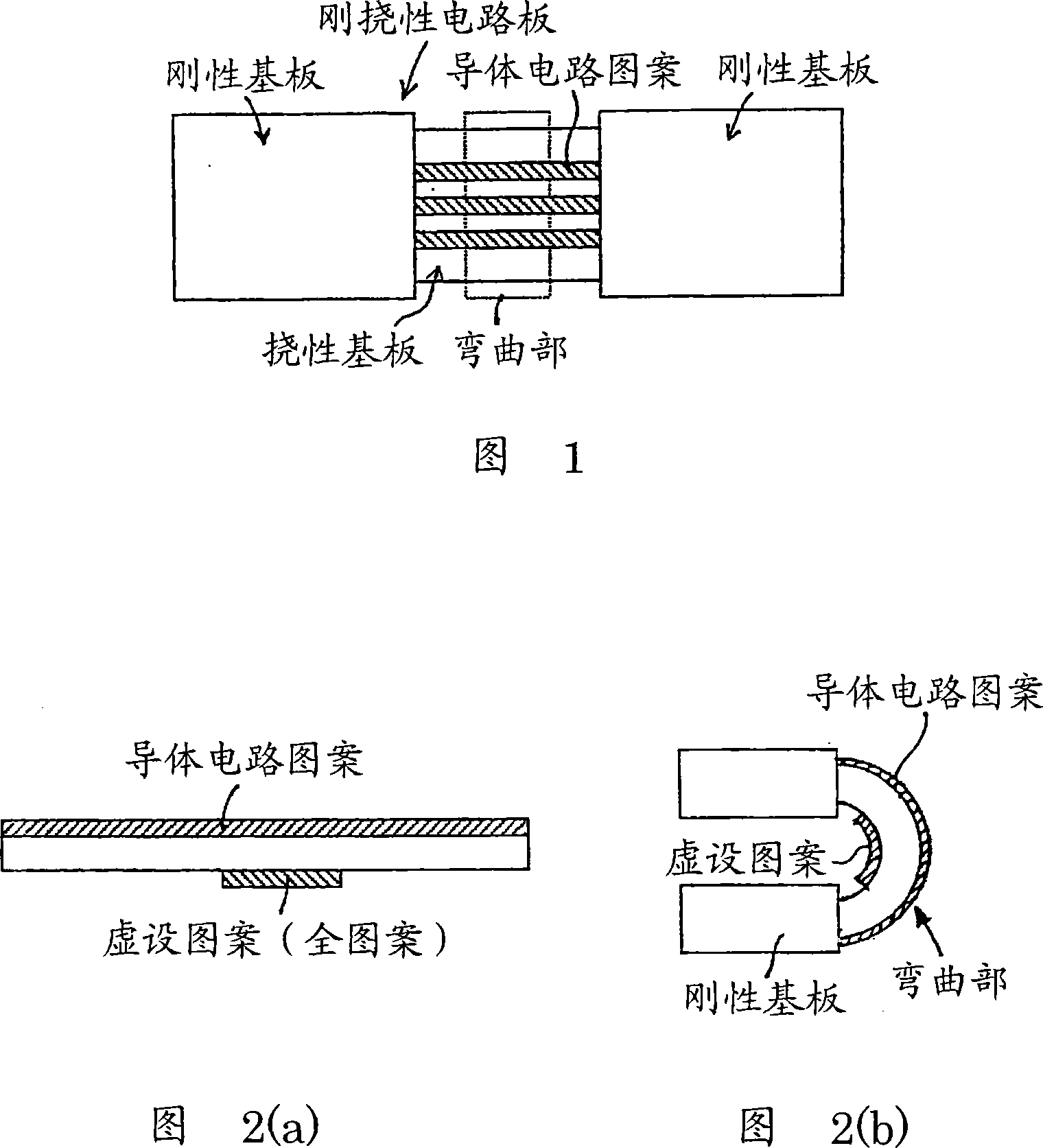

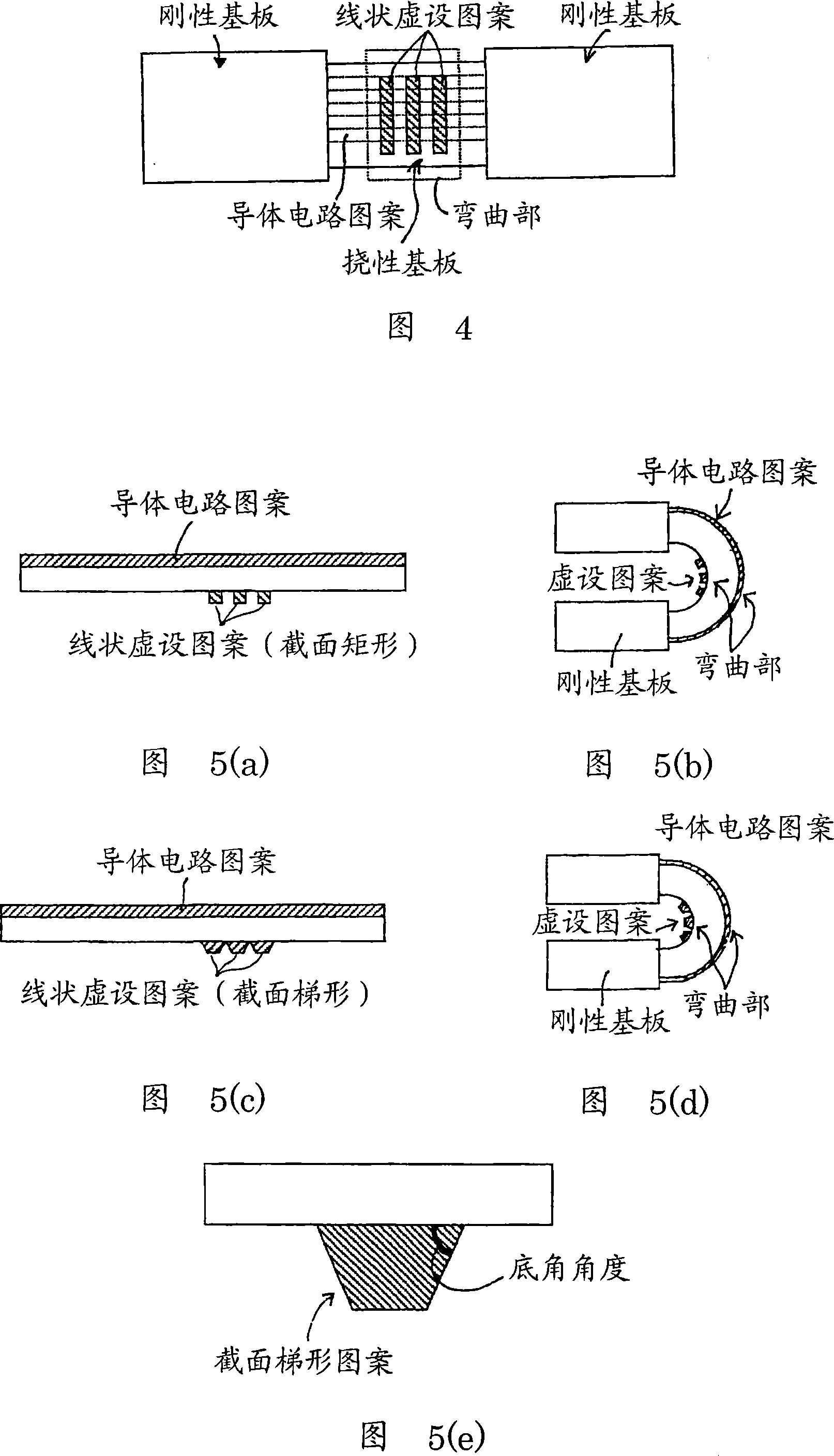

Flex-rigid wiring board and manufacturing method thereof

A technology of flexible circuit boards and flexible substrates, applied in printed circuit manufacturing, multilayer circuit manufacturing, circuit substrate materials, etc., can solve problems such as constant curvature of unbendable parts, inability to ensure strength, deformation of flexible substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0239] (A) Manufacturing process of flexible substrate

[0240] (1) When manufacturing the flex-rigid circuit board of the present invention, a double-sided copper-clad laminate (Hitachi Chemical: product name "E-67") having a thickness of 50 μm is used as a starting material for manufacturing the flexible substrate 100A constituting it. (Figure 11(a)), the double-sided copper-clad laminate is impregnated with epoxy resin in a glass fiber cloth with a thickness of 20 μm (glass fiber cloth with a thickness of 30 μm or less can be used) (the average diameter of the glass fiber Copper foil 12 having a thickness of 18 μm was laminated on both surfaces of an insulating base material 11 obtained by drying the insulating base material 11 in the thickness of 4.0 μm.

[0241] (2) The copper foil 12 laminated on both sides of the above-mentioned insulating base material 11 is etched using an aqueous copper chloride solution to form a conductor circuit pattern 13 with a line width of 300...

Embodiment 2

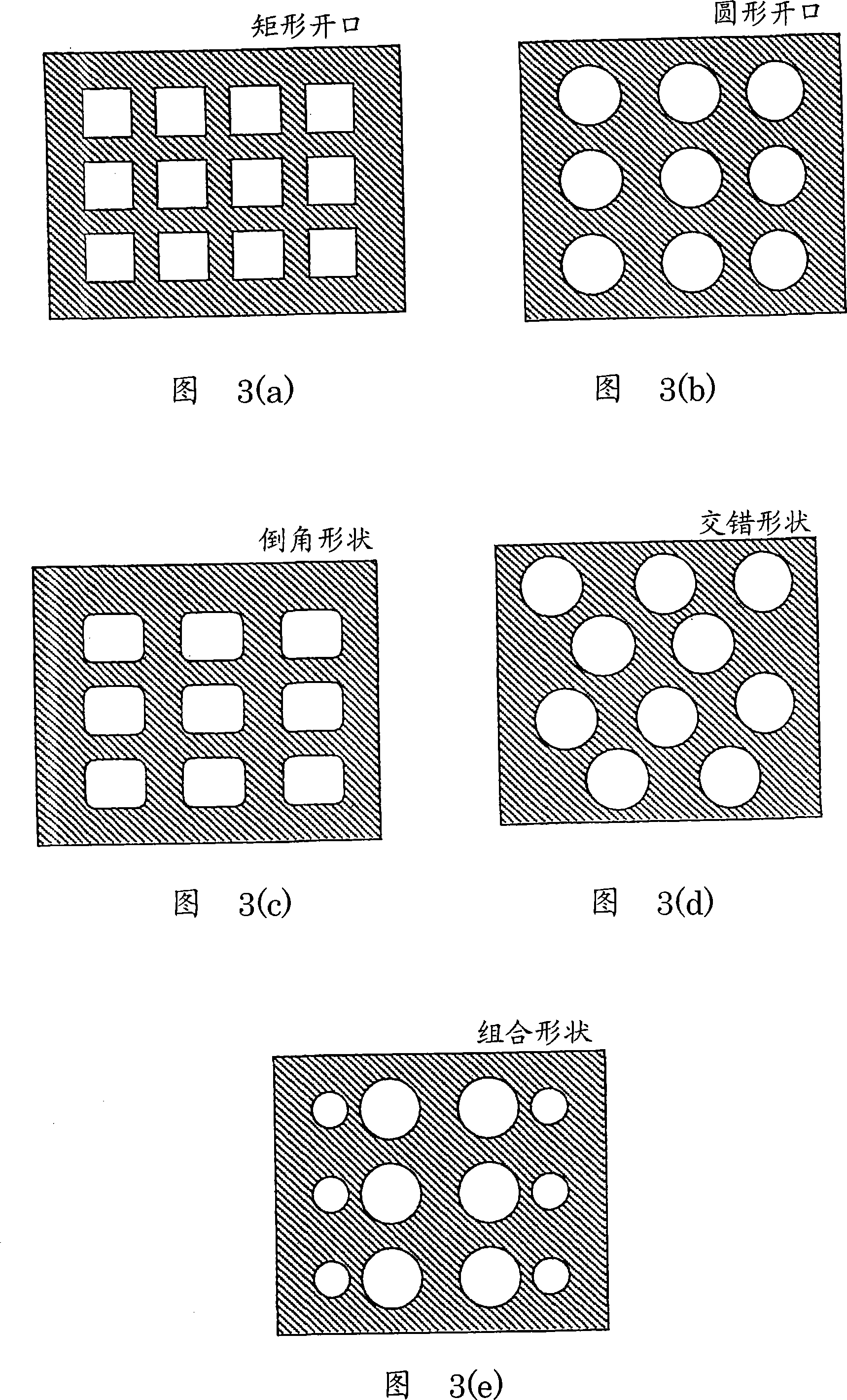

[0268] Formed on the periphery of the bending part of the flexible substrate with each opening area of 40000μm 2 The grid-shaped dummy pattern 18 with rectangular openings such that the sum of the opening areas: the area of the remainder of the pattern = 9:10 was made in the same manner as in Example 1 to manufacture the flex-rigid wiring board 300A.

Embodiment 3

[0270] Formed on the periphery of the bending part of the flexible substrate with each opening area of 90000μm 2 The grid-shaped dummy pattern 18 with rectangular openings such that the sum of the opening areas: pattern remaining area = 11:10 was the same as in Example 1 to manufacture the flex-rigid wiring board 300A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com